A device and method for preparing compound activator clinker by using semi-dry method desulfurization ash and application of the clinker

A technology of semi-dry desulfurization and combined excitation, which is applied in the restoration of polluted soil, etc., can solve the problems of high processing cost, low utilization efficiency of desulfurization ash, and complicated processing technology, so as to prevent downward movement, improve utilization efficiency and The effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

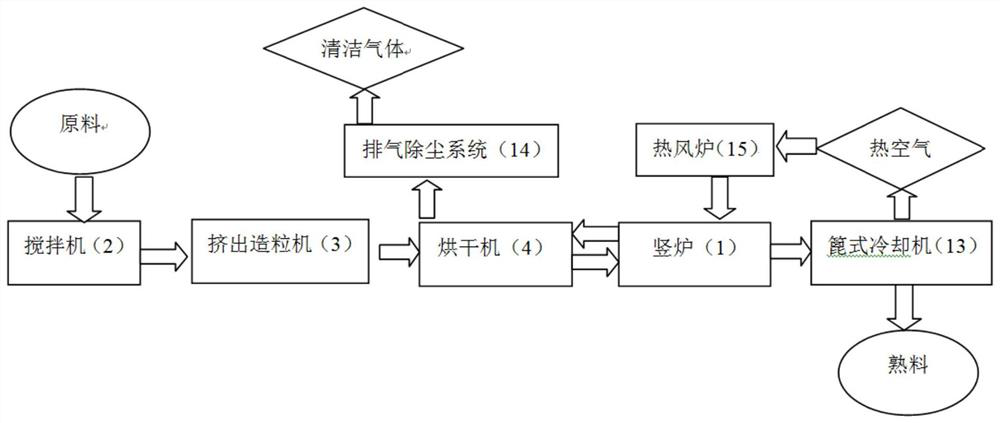

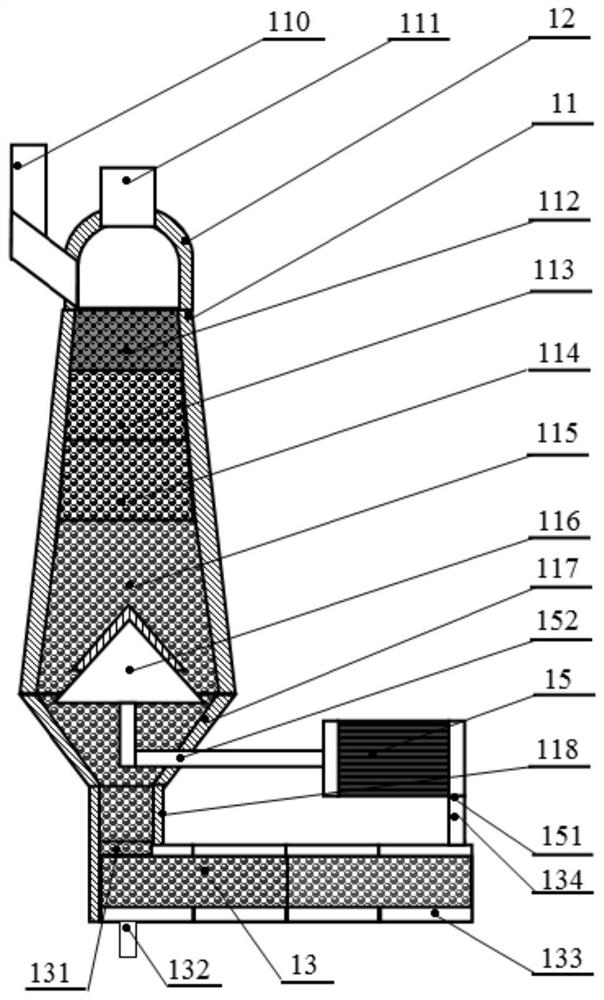

[0043] A device (sintered desulfurization ash oxidation treatment device) for preparing composite activator clinker using semi-dry desulfurization ash in this embodiment includes a shaft furnace 1, such as figure 2 As shown, the shaft furnace 1 includes a shaft furnace body 11, and the top of the shaft furnace body 11 is provided with a furnace cover 12, a feed port 110 and an exhaust gas discharge port 111, and its internal furnace includes a preheating section 112 distributed sequentially from top to bottom. , dehydration section 113, deep oxidation section 114, calcium hydroxide activation section 115 and discharge section 118, and the bottom of calcium hydroxide activation section 115 is provided with air disperser 116, and this air disperser 116 is connected with high-temperature air intake pipe.

[0044]The sintered desulfurization ash (semi-dry desulfurization ash produced in the sintering process, hereinafter referred to as "sintered desulfurization ash"), expanded per...

Embodiment 2

[0047] A device for preparing compound activator clinker using semi-dry desulfurization ash in this embodiment is basically the same in structure as in Embodiment 1, the difference mainly lies in that the cooler 13 of this embodiment adopts a grate cooler, and the bottom of the shaft furnace The discharged material is transported to the grate cooler through the hot clinker inlet 131, and the cold air is passed into the grate cooler through the cold air inlet 132 to cool the clinker. After cooling to room temperature, the composite activator clinker product obtained is cooled. Clinker outlet 133 is discharged. The hot blast outlet 134 of the grate cooler is connected to the air inlet 151 of the hot blast stove 15, and the air outlet 152 of the hot blast stove 15 is connected to the air diffuser 116 through the high-temperature air intake pipe. The hot air generated after heat exchange with the hot clinker in the grate cooler is heated by the hot blast stove 15 (using the waste ...

Embodiment 3

[0051] A method for preparing composite activator clinker using semi-dry desulfurization ash in this embodiment comprises the following steps: weighing respectively according to the mass ratio: sintering desulfurization ash, 95%; expanded perlite particles, 5%; and accounting for desulfurization Ash mass 50% water for batching. First add the desulfurized ash and water into the mixer to mix, and stir to form a slurry, then add expanded perlite to the slurry for stirring, the stirring time is 5 minutes, the stirring speed is 15 rpm, and the mud is formed after mixing well. Then the mud is taken out, and the mud is extruded into circular segment-shaped raw meal particles with a diameter of 10mm with an extrusion granulator, and it is first dried with a dryer to a green body with a certain strength (cylinder compressive strength 0.5MPa ), then add in the shaft furnace among the embodiment 2 and carry out deep oxidation reaction operation, reaction comprises: preheating, mud materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com