Seaweed cracking method and application thereof in fermentation hydrogen production

A kind of seaweed, cracking liquid technology, applied in the direction of fermentation, can solve the problems of refractory brown macromolecular substances, consumption of organic matter, long reaction time, etc., to achieve cheap and easy to obtain substrate sources, promote full release, and eliminate inhibition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

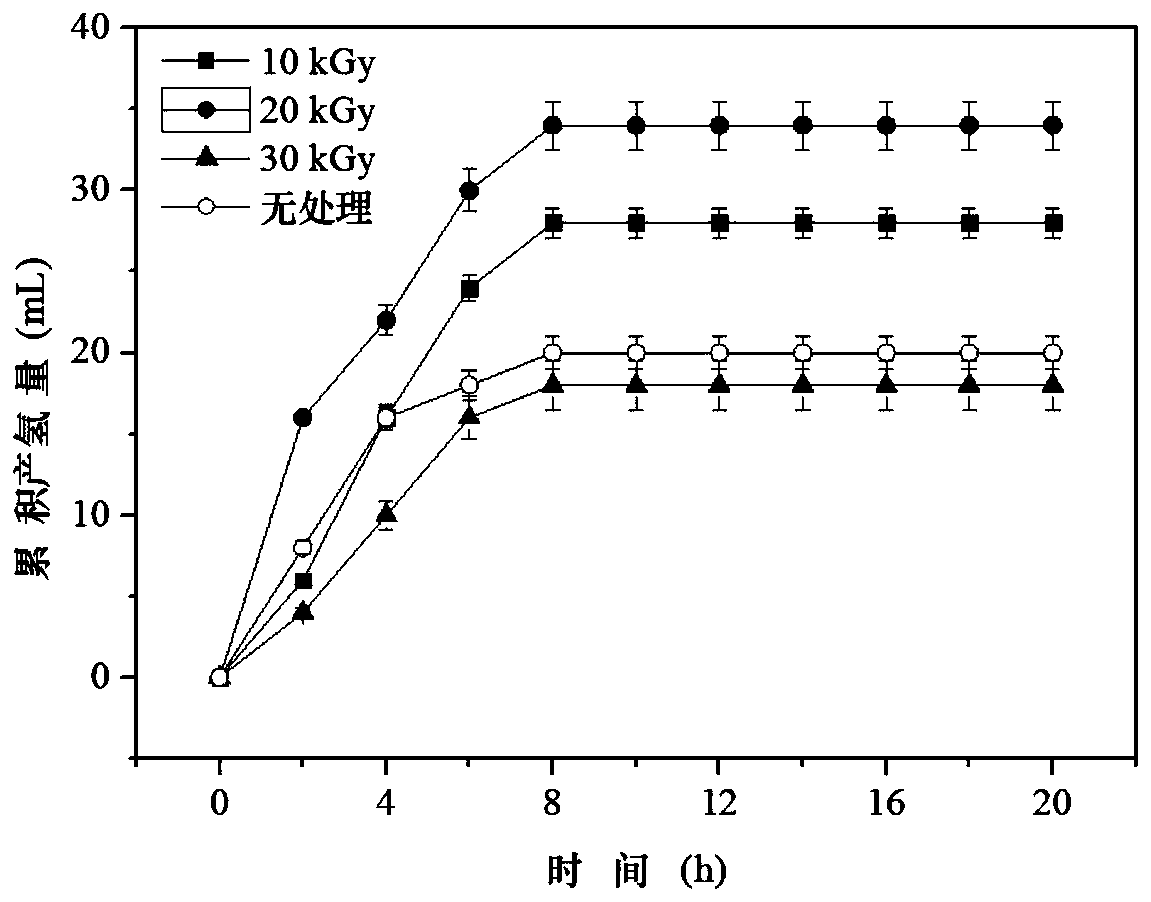

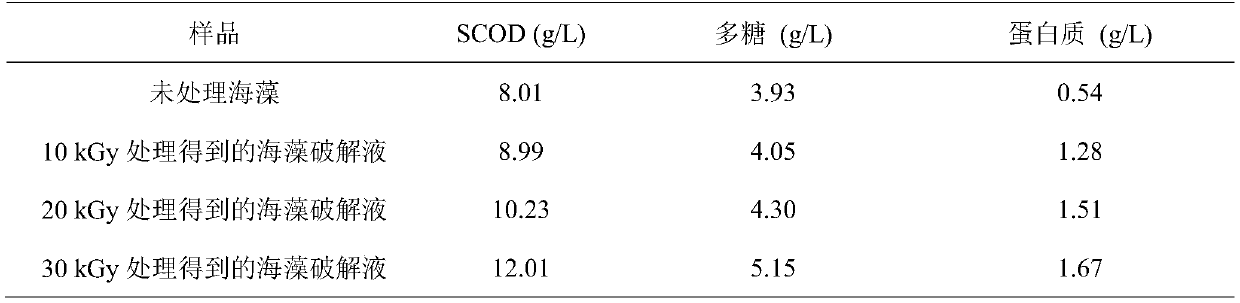

[0028] The cracking effect of 10-30kGy dose irradiation on seaweed:

[0029] Take 30g of dried and pulverized seaweed particles and place them in a 1L ground-mouth bottle, add 970mL of deionized water to it to obtain a mixed solution with a seaweed concentration of 30g TS / L. Prepare 3 bottles of seaweed and water mixture in the same way. The three mixtures were irradiated with gamma rays at doses of 10, 20 and 30 kGy at room temperature, and the radiation source was 60 Co. After the irradiation, the seaweed cracking solution was obtained; the indicators in the untreated seaweed and the seaweed cracking solution treated with each irradiation dose were analyzed, and the cracking effect of the seaweed was obtained as shown in Table 1.

[0030] Table 1 The cracking effect of 10-30kGy dose irradiation on seaweed

[0031]

[0032] It can be seen from Table 1 that the released amount of SCOD, polysaccharide and protein increases with the increase of ionizing radiation dose in s...

Embodiment 2

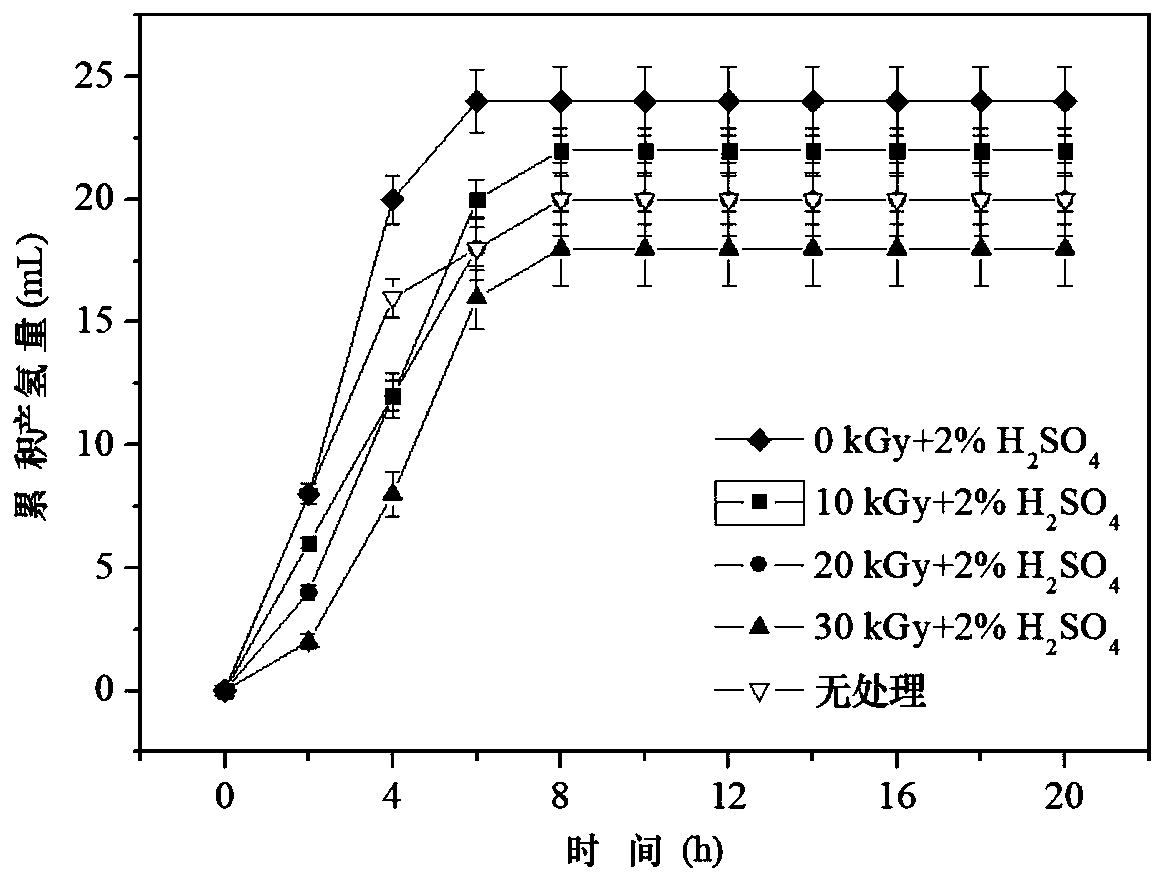

[0034] 0-30kGy dose irradiation with 2% H 2 SO 4 The cracking effect of coupling processing seaweed:

[0035] Take 30g of dried and pulverized seaweed particles and place them in a 1L ground-mouth bottle, add 970mL of deionized water to it to obtain a mixed solution with a seaweed concentration of 30g TS / L. Prepare 4 bottles of seaweed and water mixture in the same way. Add 2% concentrated H of the mixed solution quality of seaweed and water to 4 bottles of mixed solution 2 SO 4 , and received γ-ray irradiation with doses of 0, 10, 20 and 30kGy at room temperature, and the radiation source was 60 Co. After the irradiation, adjust the pH of the mixed solution to 7.0 with NaOH to obtain the seaweed cracking solution; analyze the untreated seaweed and each irradiation dose with H 2 SO 4 The results of seaweed cracking are shown in Table 2 by coupling the various indicators in the obtained seaweed cracking solution.

[0036] Table 2 0-30kGy dose irradiation with 2% H 2 SO...

Embodiment 3

[0040] 0-30kGy dose irradiation coupled with 2% NaOH cracking effect of seaweed treatment:

[0041] Take 30g of dried and pulverized seaweed particles and place them in a 1L ground-mouth bottle, add 970mL of deionized water to it to obtain a mixed solution with a seaweed concentration of 30g TS / L. Prepare 4 bottles of seaweed and water mixture in the same way. Add 2% NaOH powder of seaweed and water mixed solution to 4 bottles of mixed solution, and accept gamma ray irradiation with doses of 0, 10, 20 and 30 kGy respectively at room temperature, and the radioactive source is 60 Co. After the irradiation, use H 2 SO 4 Adjust the pH of the mixed solution to 7.0 to obtain the seaweed cracking solution; analyze the untreated seaweed and various indicators in the seaweed cracking solution coupled with each irradiation dose and NaOH, and obtain the cracking effect of the seaweed as shown in Table 3.

[0042] Table 3 Cracking effect of 0-30kGy dose irradiation and 2% NaOH coupled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com