Solid carbon sulfonic acid catalyst, preparation method thereof, tributyl citrate, and preparation method of tributyl citrate

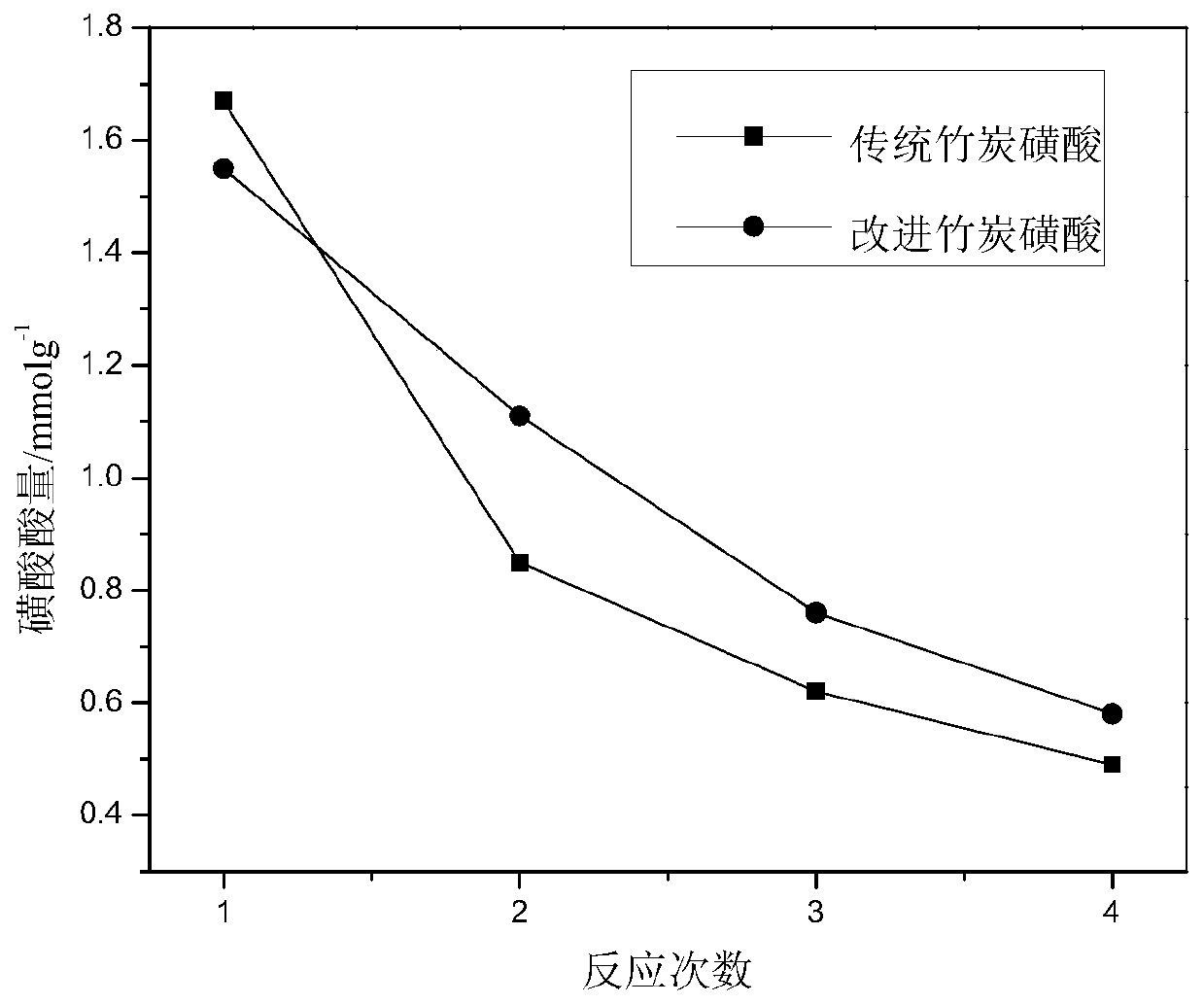

A technology of tributyl citrate and carbon sulfonic acid is applied in the field of plasticizers to achieve the effects of improving stability and improving repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

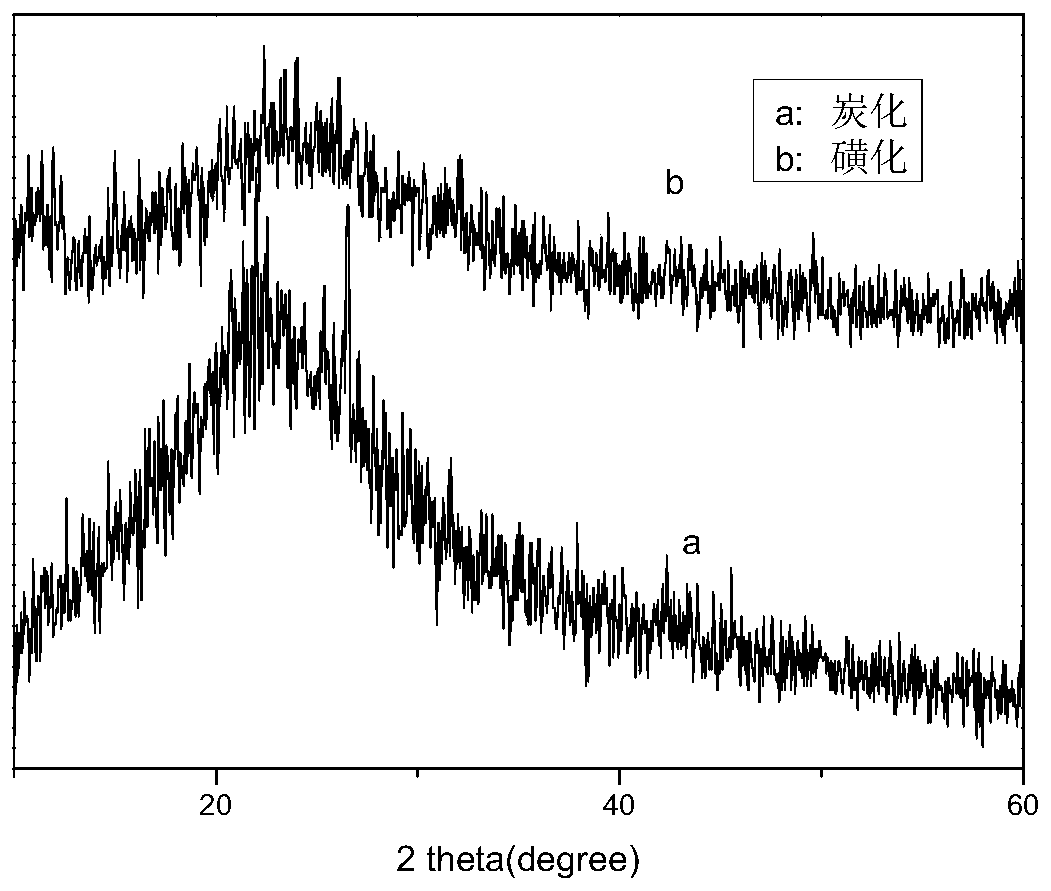

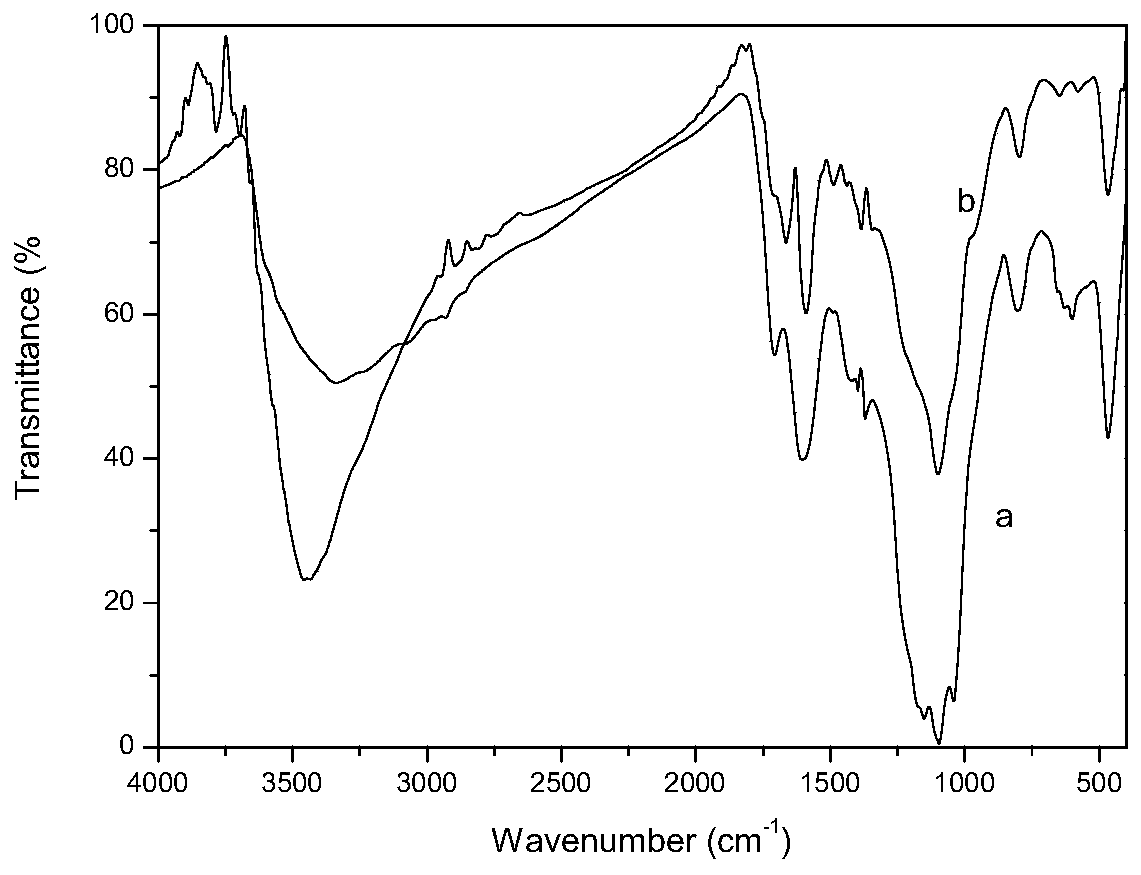

[0037] The preparation method of the solid charcoal sulfonic acid catalyst of one embodiment, comprises the steps:

[0038] S10, soaking the bamboo powder in sodium silicate solution for 15h-20h, then soaking the bamboo powder in deionized water to achieve adsorption equilibrium, filtering and drying, and then heat-treating at 130°C-150°C for 3h-5h, Bamboo powder after alkaline pretreatment is obtained.

[0039] Preferably, bamboo powder is prepared through the following steps:

[0040] Bamboo is used as raw material, after being washed with water and dried, it is successively ground in a pulverizer, sieved with a sieve of 50 mesh to 70 mesh, and vacuum dried at a temperature of 50 DEG C to obtain bamboo powder.

[0041] The purpose of alkaline pretreatment of bamboo powder is to make sodium silicate saturated and adsorbed in the structure of bamboo powder, so that there will be no residual sodium silicate attached to the surface of bamboo powder.

[0042] S20. Mix the alkal...

Embodiment 1

[0066] The preparation of embodiment 1 solid charcoal sulfonic acid catalyst

[0067] The bamboo powder pulverized with pulverizer is sieved with 60 mesh sieves, and vacuum-dried at 50 ℃ of temperature. After cooling, the bamboo powder is taken out, and the dry bamboo powder of 10g is weighed rapidly. Bamboo powder was soaked in 10% sodium silicate solution by equal-volume immersion method, soaked for 16 hours, then soaked in deionized water to reach adsorption equilibrium, filtered and dried, and passed water vapor in tube furnace for 140 ℃ heat treatment for 4h.

[0068] Add hydrochloric acid to the bamboo powder after alkaline pretreatment with sodium silicate to adjust the pH, so that the sodium silicate in the bamboo powder is converted into silicic acid. The bamboo powder was treated with 5% p-toluenesulfonic acid, heat treated with water vapor at 140° C. in a tube furnace, and then heated to 200° C. for 2 hours to obtain a pretreated composite bamboo material.

[006...

Embodiment 2

[0071] The preparation of embodiment 2 tributyl citrate

[0072] Add 0.1mol citric acid and 0.45mol n-butanol in a molar ratio to a 150ml three-necked flask equipped with a water separator, a thermometer, a reflux condenser and a stirring bar, then add 0.1g of solid carbon sulfonic acid catalyst, mix well, and simultaneously take Record the acid value of the reaction solution before the reaction, heat and stir with a collector-type constant temperature heating magnetic stirrer, stir to raise the temperature to a certain value, keep this temperature and reflux for 4 hours, and regularly take samples to measure the acid value of the reaction solution (according to GB / T1668 [93] method).

[0073] Heat the three-necked bottle with a water separator and a reflux device until the reflux starts to calculate the time, and stop the reaction when no water drops are separated. After the product is cooled and dipped, pour out the reaction solution and first recover n-butanol by normal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com