Preparation method of 3-(cyclohexylamino)-1-propanesulfonic acid

A technology of cyclohexylamine and propanesulfonic acid, which is applied in the preparation of sulfonic acid, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as unrecorded yield and complex process, and achieve improved production capacity and products. The yield, the process steps are simple, and the operation process is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

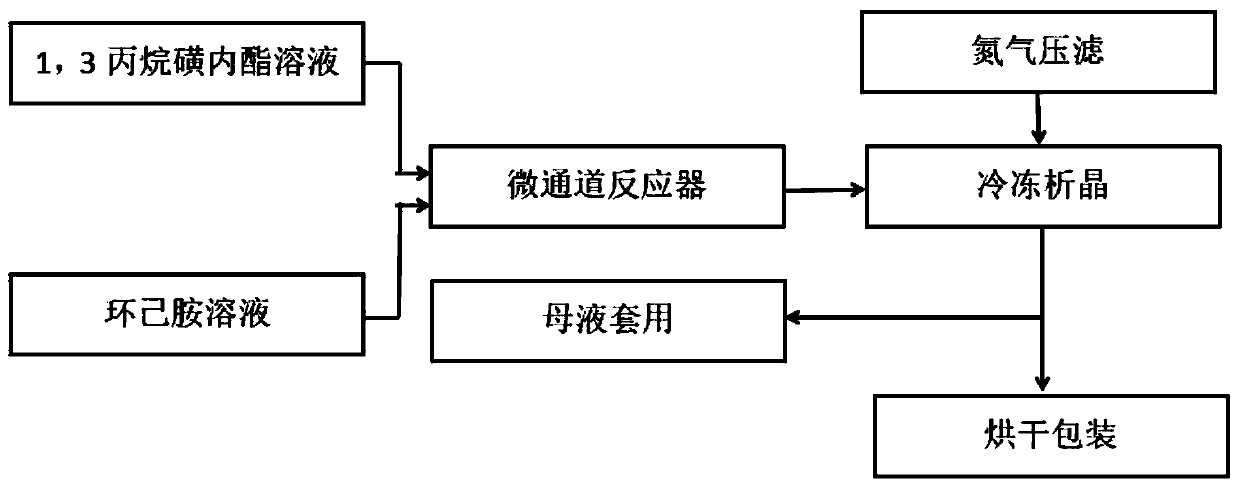

Method used

Image

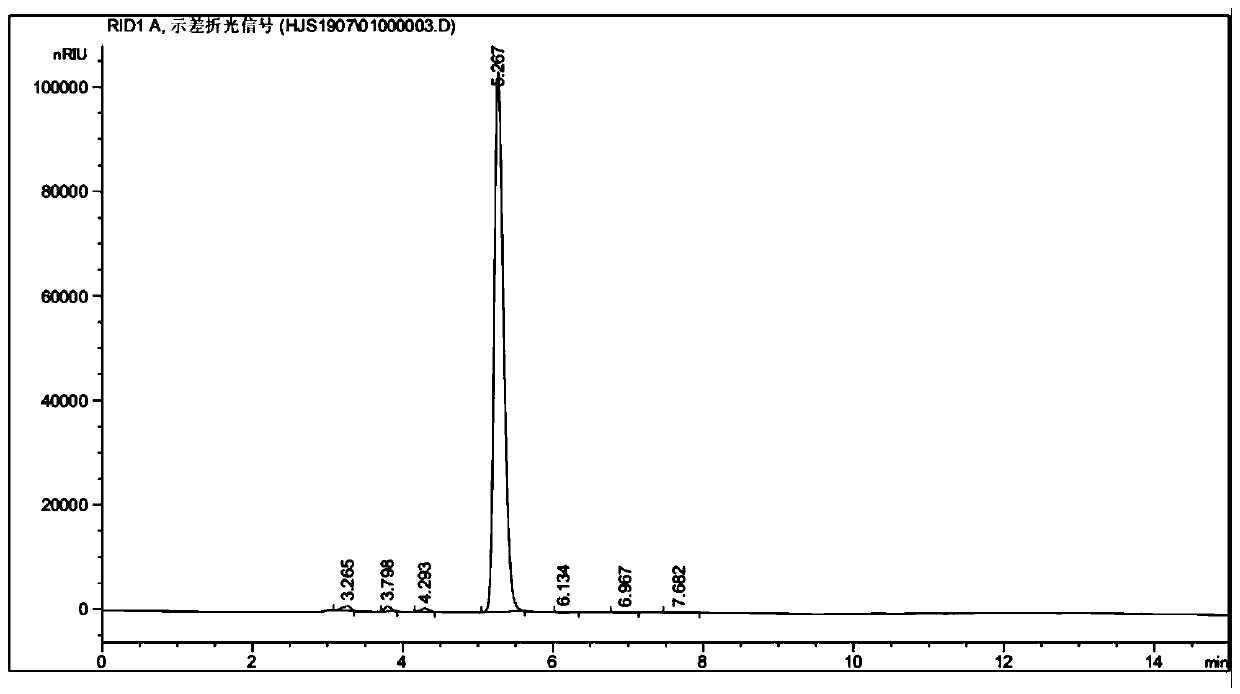

Examples

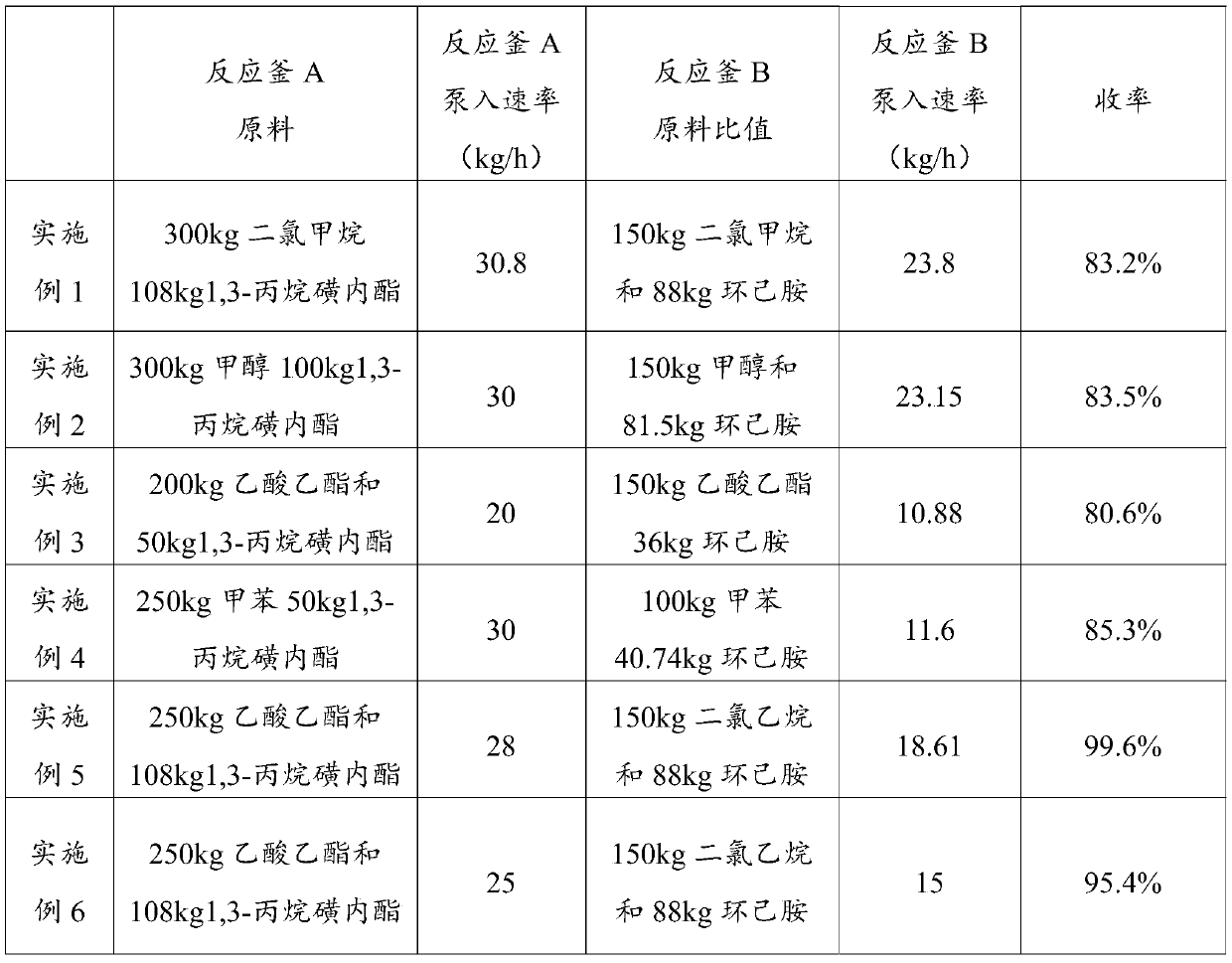

Embodiment 1

[0025] 1, Embodiment 1 of the present invention provides a kind of preparation method of 3-(cyclohexylamine)-1-propanesulfonic acid, comprises the steps:

[0026] 2. Add 300kg of dichloromethane and 108kg of electronic grade 1,3-propane sultone into the 500L enamel reaction kettle A with mechanical stirring, and stir to dissolve at room temperature;

[0027] 3. Add 150kg of dichloromethane and 88kg of cyclohexylamine into the 500L enamel reaction kettle B with mechanical stirring, and stir evenly at room temperature;

[0028] 4. Through the metering pump, pump the liquid in kettle A at 30.8kg / h, and the solution in kettle B at 23.8kg / h, and simultaneously pump them into the microchannel reactor for reaction;

[0029] 5. Collect the reaction solution in a 1000L kettle, freeze and crystallize;

[0030] 6. Feed nitrogen gas into the crystallizer and press into a fully automatic stainless steel filter. After passing the test, the obtained crystals are dried and packaged, and the ...

Embodiment 2

[0032] Embodiment 2 of the present invention provides a kind of preparation method of 3-(cyclohexylamine)-1-propanesulfonic acid, comprises the steps:

[0033] (1) Add 300kg of methanol and 100kg of electronic grade 1,3-propane sultone into a 500L enamel reactor A with mechanical stirring, and stir to dissolve at room temperature;

[0034] (2) Add 150kg methanol and 81.5kg cyclohexylamine in the 500L enamel reactor B with mechanical stirring, and stir evenly at room temperature;

[0035] (3) by metering pump, the liquid in the A kettle is pumped into the microchannel reactor simultaneously with 30kg / h, and the solution in the B kettle is reacted at 23.15kg / h;

[0036] (4) Collect the reaction solution with a 1000L kettle, freeze and crystallize;

[0037] (5) Nitrogen gas is introduced into the crystallization kettle, and a fully automatic stainless steel filter is pressed into it. After the obtained crystals pass the test, they are dried and packaged, and the methanol mother ...

Embodiment 3

[0039] Embodiment 3 of the present invention provides a kind of preparation method of 3-(cyclohexylamine)-1-propanesulfonic acid, comprises the steps:

[0040] (1) Add 200kg of ethyl acetate and 50kg of electronic grade 1,3-propane sultone to a 500L enamel reactor A with mechanical stirring, and stir to dissolve at room temperature;

[0041] (2) Add 150kg ethyl acetate and 36kg cyclohexylamine in the 500L enamel reaction kettle B with mechanical stirring, stir evenly at room temperature;

[0042] (3) by metering pump, with 20kg / h of liquid in the still of A, with 10.88kg / h of solution in the still of B, pump into microchannel reactor simultaneously and react;

[0043] (4) Collect the reaction solution with a 1000L kettle, freeze and crystallize;

[0044] (5) Feed nitrogen into the crystallizer, press into a full-automatic stainless steel filter, the obtained crystals pass the test, dry and pack, and the ethyl acetate mother liquor is recycled to the next batch of production. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com