Equipment and method for preparing high-purity tellurium

A technology for high-purity tellurium and equipment, which is applied in the field of industrialized preparation of high-purity tellurium, can solve the problems of poor tellurium purification effect, high energy consumption, low distillation efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

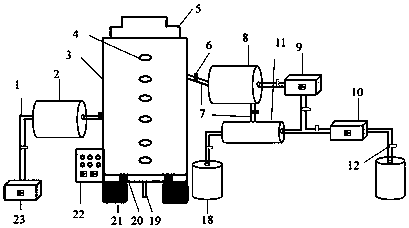

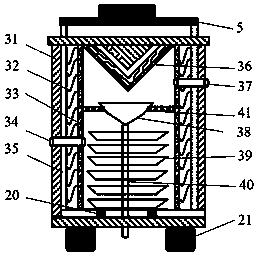

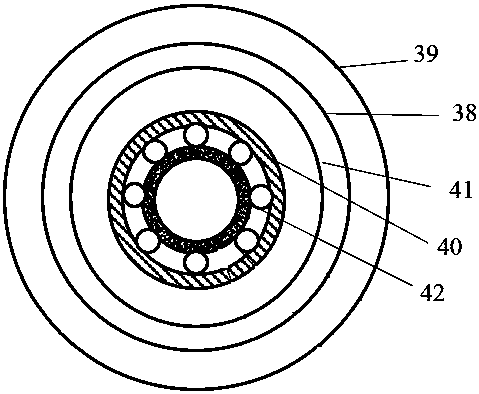

[0073] Evenly place 5 kg of crude tellurium raw material with a purity of 5N in a clean 6-layer graphite retort 39, record the data displayed by the weight sensor 20, fix and seal the sampling monitoring tube 19, graphite tray 41, collecting funnel 38 and distillation top in sequence. Cover 5, open single-hole vacuum suction filter 23 and double-hole vacuum suction filter 9 to carry out vacuum treatment, vacuum still 3, molten metal buffer kettle 8, hydrogen reduction furnace 11 and each molten metal feeding pipe 7 that is connected are in a vacuum state. Wait for the vacuum degree to reach 8×10 -3 After pa, turn on the high-frequency heating device for heating, control the internal heating temperature of the vacuum distillation kettle 3 to about 500°C, and keep the temperature of the conical condenser 36 and the vertical sampling detection tube 19 at 270°C for 4 hours. During this process, the crude tellurium raw material gradually melts, and The impurity elements whose satu...

Embodiment 2

[0083] Evenly place 5 kg of crude tellurium raw material with a purity of 5N in a clean 6-layer graphite retort 39, record the data displayed by the weight sensor, fix and seal the sampling monitoring tube 19, graphite tray 41, collecting funnel 38 and distillation top cover in sequence 5, open the single-hole vacuum suction filter 23 and the double-hole vacuum suction filter 9 to carry out vacuum treatment, the vacuum still 3, the molten metal buffer kettle 8, the hydrogen reduction furnace 11 and each molten metal feeding pipe 7 connected in a vacuum. Wait for the vacuum degree to reach 9×10 -3 After pa, turn on the high-frequency heating device to heat, control the internal heating temperature of the vacuum distillation kettle 3 to about 505°C, and the temperature of the conical condenser 36 and the vertical sampling detection tube 19 to be 273°C for 4 hours. During this process, the tellurium raw material gradually melts and becomes saturated. The impurity elements whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com