Device and method for treating phenol-containing coal chemical industry wastewater by advanced oxidation method in cooperation with immobilized white-rot fungi

A technology for coal chemical wastewater and white rot fungi, which is applied in biological treatment devices, chemical instruments and methods, oxidized water/sewage treatment, etc. Degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

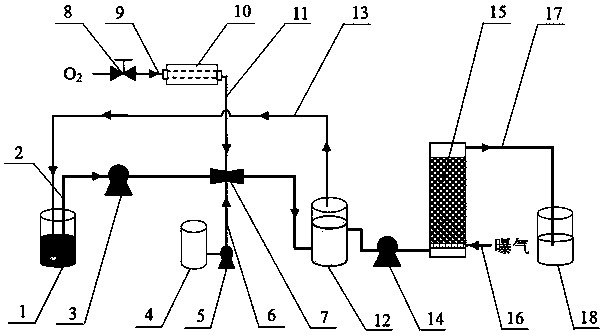

Method used

Image

Examples

Embodiment 1

[0038] This embodiment adopts batch processing mode to test device and method provided by the invention

[0039] Take domestic sewage to simulate phenol-containing wastewater for experiment, take 20L of domestic sewage from the sewage plant, add phenol to make the phenol concentration in the raw water 500 mg / L (the determination method of phenol content is 4-aminoantipyrine method), and then use the device O 3 / H 2 o 2 Carry out oxidation treatment, water pump flow rate 1 L / min, adjust O 3 Generator 10 makes O 3 The total dosage is 50mg / L, adjust the peristaltic metering pump 5 to make H 2 o 2 The dosage is 50 mg / L, the oxidation treatment is 20 minutes, and then 10 L of the oxidized wastewater is added to the white rot fungus biofilm reactor 15, and the batch treatment is adopted. The hydraulic retention time of the biofilm is 24 hours, and the aeration adopts intermittent aeration Aerate once every 3 hours, 5 minutes each time. After treatment, the concentration of phe...

Embodiment 2

[0042] This embodiment adopts continuous processing mode to test device and method provided by the invention

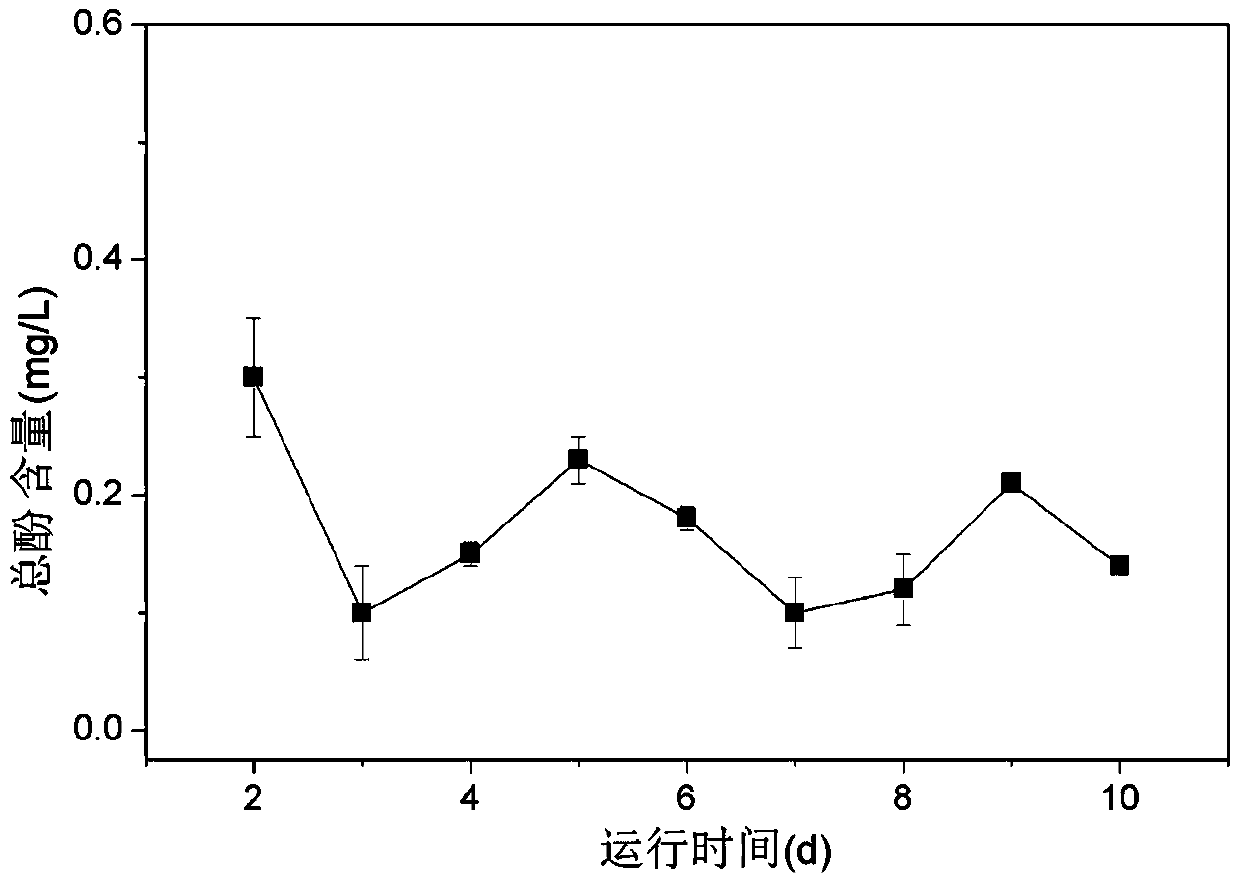

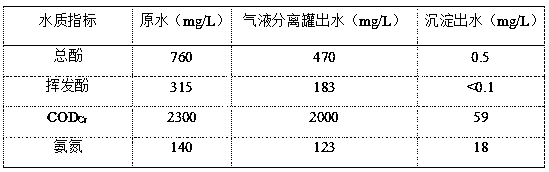

[0043] The waste water after recovery of phenol and ammonia in coal-to-gas enterprises (see Table 1 for the quality of waste water before and after treatment), first oxidizes the waste water for 30 min through the oxidation treatment unit in the system, and adjusts the O 3 Generator 10 and peristaltic metering pump 5 make total dosing of oxidant O 3 and H 2 o 2 The dosage is 100 mg / L and 50 mg / L, the flow rate of the water pump is 3 L / min, and the contact reaction time is 30 min. After oxidation treatment, the wastewater enters the white rot fungus biofilm reactor 15 through the peristaltic metering pump 5, and the flow rate of the metering pump is 4 mL / min. min, while the white-rot fungus biofilm reactor 15 is continuously aerated, the air flow rate is 150mL / min, the hydraulic retention time of the white-rot fungus biofilm reactor 15 is 48 h, and the waste water af...

Embodiment 3

[0047] This embodiment adopts batch processing mode to test device and method provided by the invention

[0048] Take phenol-containing coal chemical wastewater sample 2 (see Table 2 for the water quality conditions of water sample 2), and use the system oxidation unit to oxidize and degrade the wastewater to adjust O 3 Generator 10 and peristaltic metering pump 5 make the oxidant O 3 and H 2 o 2 The dosage is 120 mg / L and 40 mg / L respectively, the flow rate of the water pump is 5 L / min, and the contact oxidation time is 40 min. After the oxidation treatment, the coal chemical industry wastewater is stored in the gas-liquid separation tank, and then the white rot fungus biofilm reactor 15 The wastewater after oxidation treatment is biodegraded. The influent flow rate of the white rot fungus biofilm reactor 15 is 10 mL / min, the aeration interval is 3 h, each aeration is 5 min, the air flow rate is 300 mL / min, and the hydraulic retention of the biofilm The time was 36 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com