Shell powder-based porous high-temperature-resistant material as well as preparation method and application thereof

A technology of shell powder and high temperature resistance, which is applied in the field of porous high temperature materials, can solve the problems of inability to achieve continuous purification, adsorption, inability to continuously remove harmful gases, and the adsorption performance needs to be improved, and achieves high strength and good thermal shock resistance. , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

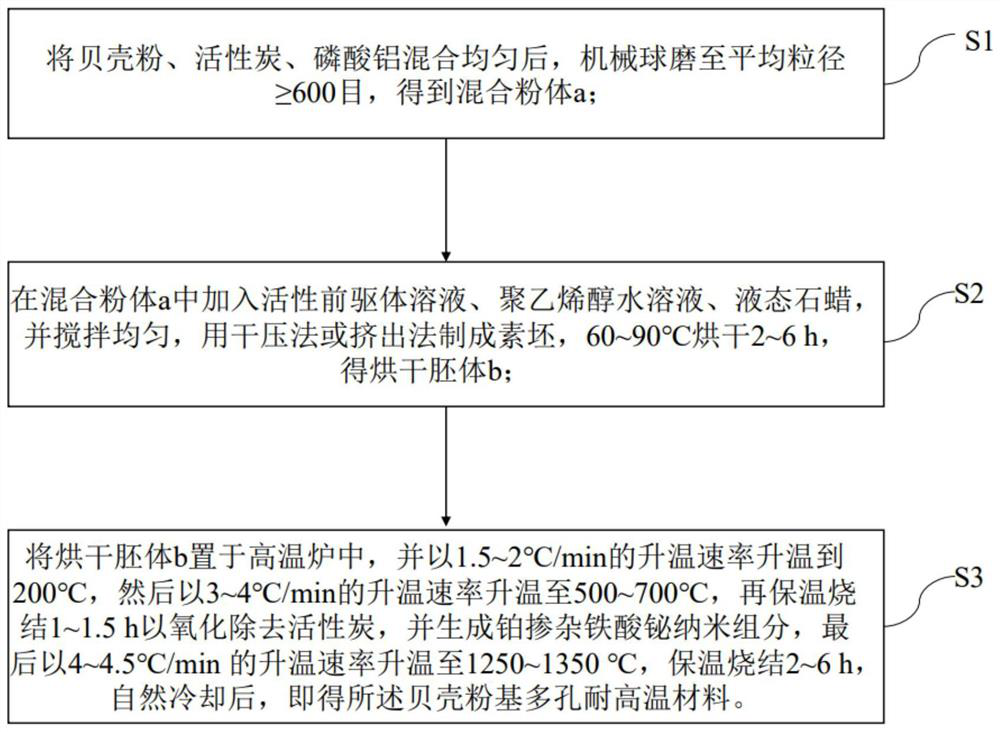

[0031] A preparation method of a shell powder-based porous high-temperature-resistant material, comprising the following steps:

[0032] (1) Add ferric nitrate, bismuth nitrate, and chloroplatinic acid into deionized water, stir to dissolve, add cetyltrimethylammonium bromide, and stir in a water bath at 60°C for 3 hours to obtain an active precursor solution; the soluble The dosage ratio of iron salt, soluble bismuth salt, chloroplatinic acid, deionized water and cetyltrimethylammonium bromide is 0.1mol: 0.1mol: 0.01mol: 200mL: 3g;

[0033] (2) Weigh 80 parts of shell powder, 5 parts of activated carbon, 3 parts of aluminum dihydrogen phosphate, 3 parts of active precursor solution, 2 parts of polyvinyl alcohol aqueous solution with a mass fraction of 1%, and 1 part of light wax oil in order by mass parts ;

[0034] (3) After uniformly mixing the shell powder, activated carbon, and aluminum dihydrogen phosphate, mechanical ball milling until the average particle size is ≥ 60...

Embodiment 2

[0038] A preparation method of a shell powder-based porous high-temperature-resistant material, comprising the following steps:

[0039] (1) Add ferric chloride, bismuth chloride, and chloroplatinic acid into deionized water, stir and dissolve, add polyvinylpyrrolidone, and stir in a water bath at 60°C for 5 hours to obtain an active precursor solution; the soluble iron salt, soluble bismuth The dosage ratio of salt, chloroplatinic acid, deionized water and structure directing agent is 0.1mol: 0.1mol: 0.02mol: 200mL: 4g;

[0040] (2) Weigh in turn 85 parts of shell powder, 10 parts of activated carbon, 4 parts of aluminum tripolyphosphate, 5 parts of active precursor solution, 3.5 parts of polyvinyl alcohol aqueous solution with a mass fraction of 6%, and 5.5 parts of heavy wax oil ;

[0041] (3) After uniformly mixing the shell powder, activated carbon, and aluminum tripolyphosphate, mechanical ball milling until the average particle size is ≥ 600 mesh, to obtain the mixed p...

Embodiment 3

[0045] A preparation method of a shell powder-based porous high-temperature-resistant material, comprising the following steps:

[0046] (1) Add ferric nitrate, bismuth acetate, and chloroplatinic acid into deionized water, stir and dissolve, add a structure-directing agent, and stir in a water bath at 60°C for 6 hours to obtain an active precursor solution; the soluble iron salt, soluble bismuth salt, The dosage ratio of chloroplatinic acid, deionized water and cetyltrimethylammonium bromide is 0.1mol: 0.1mol: 0.03mol: 200mL: 5g;

[0047](2) Weigh 90 parts of shell powder, 15 parts of activated carbon, 5 parts of aluminum metaphosphate, 7 parts of active precursor solution, 5 parts of polyvinyl alcohol aqueous solution with a mass fraction of 10%, and 10 parts of light wax oil in order by mass parts;

[0048] (3) After uniformly mixing the shell powder, activated carbon and aluminum metaphosphate, mechanical ball milling until the average particle size is ≥ 600 mesh, to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com