Fluorine-containing superhydrophobic porous material for oil-water separation and preparation method thereof

A technology for porous materials and oil-water separation, applied in the field of composite materials, can solve the problems of high temperature resistance, low acid and alkali resistance, low chemical inertness, and insufficient hydrophobic and lipophilic properties, achieve good hydrophobic and lipophilic properties, improve oil-water separation efficiency, and facilitate The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of a fluorine-containing superhydrophobic porous material for oil-water separation, the steps are as follows:

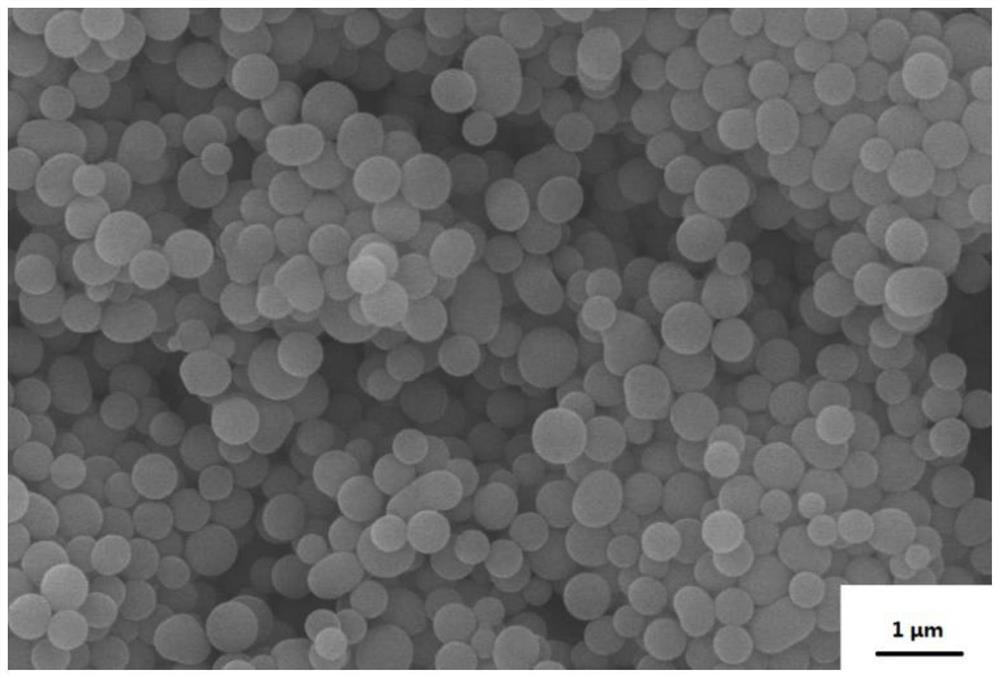

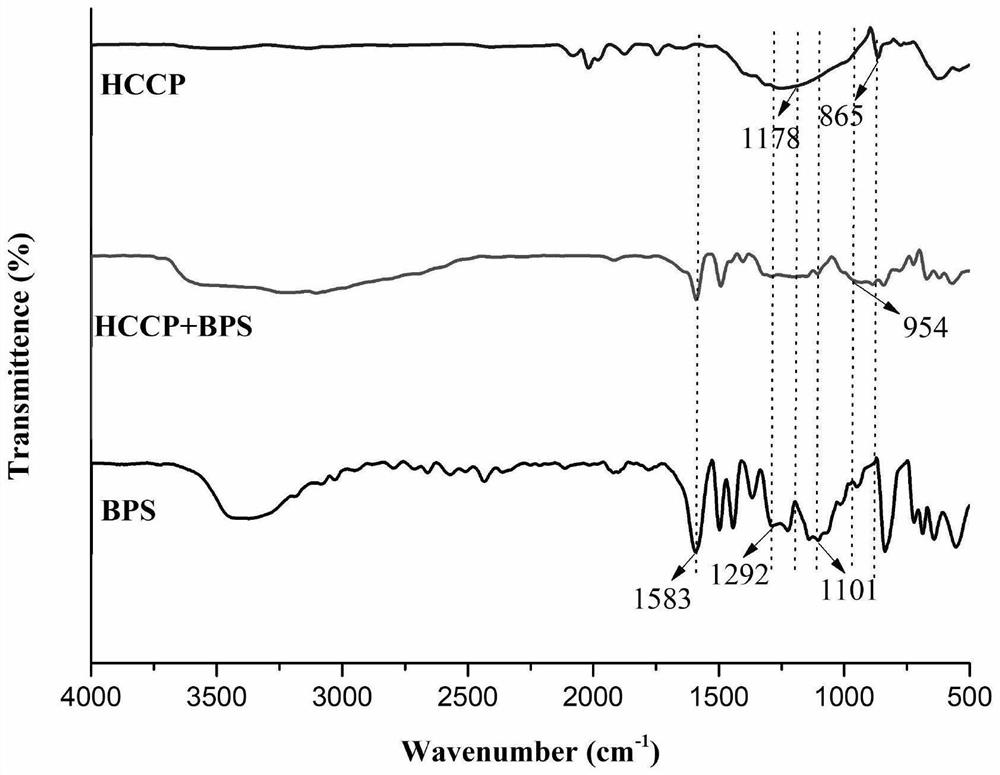

[0043] (1) 80 parts by weight of hexachlorocyclotriphosphazene, 230 parts by weight of bisphenol S, and 20,000 parts by weight of acetonitrile were mixed uniformly, ultrasonicated at 40 Hz, reacted at 50°C for 30 minutes, added 8 parts by weight of triethylamine, and heated at 50°C Ultrasonic reaction for 4 hours. The obtained product was washed with acetone, ethanol and deionized water respectively, centrifuged three times, and dried at 50° C. for 5 hours to finally obtain polyphosphazene microspheres with a particle diameter of about 0.5 microns.figure 1 It is the bisphenol S polyphosphazene microsphere figure described in embodiment 1, and its diameter is about 0.5 micron. figure 2 It is the infrared image of bisphenol S polyphosphazene microspheres described in embodiment 1, 1292cm -1 It is the O=S=O absorption peak.

[0044] (2) 20...

Embodiment 2

[0048] A preparation method of a fluorine-containing superhydrophobic porous material for oil-water separation, the steps are as follows:

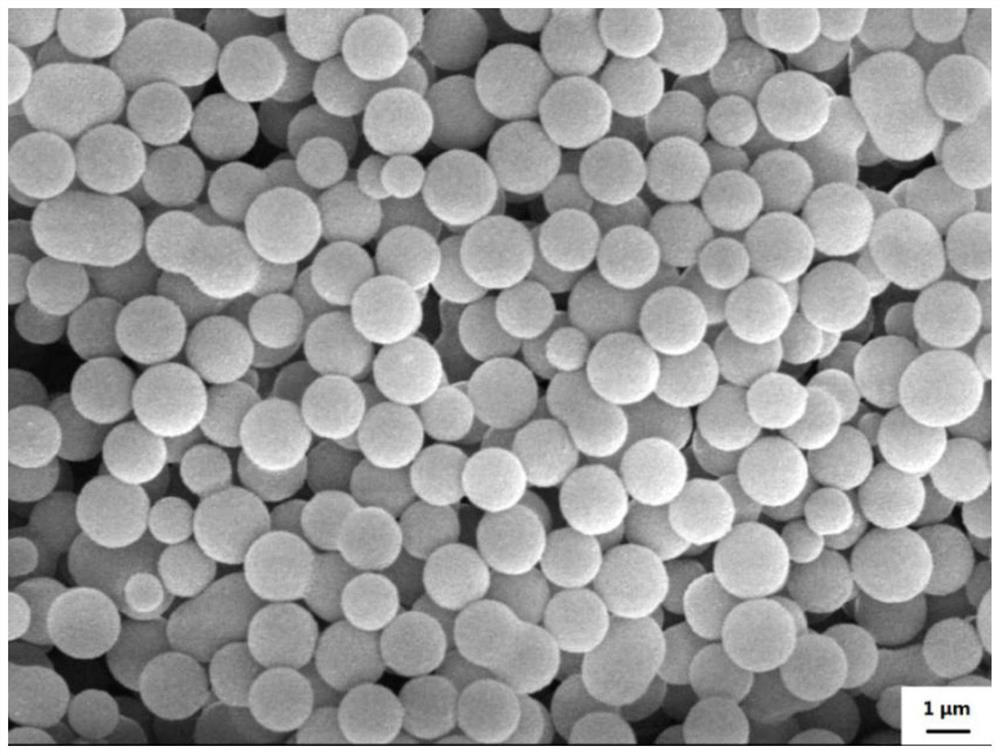

[0049] (1) 80 parts by weight of hexachlorocyclotriphosphazene, 230 parts by weight of bisphenol F, and 20,000 parts by weight of acetonitrile were uniformly mixed, ultrasonicated at 40 Hz, reacted at 50°C for 30 minutes, added 8 parts by weight of triethylamine, and heated at 50°C Ultrasonic reaction for 4 hours. The obtained product was washed with acetone, ethanol and deionized water respectively, centrifuged three times, and dried at 50° C. for 5 hours to finally obtain polyphosphazene microspheres with a particle diameter of about 1 micron. image 3 It is the bisphenol F polyphosphazene microsphere figure described in embodiment 2, and its diameter is about 1 micron. Figure 4 It is the infrared figure of bisphenol F polyphosphazene microspheres described in embodiment 2, 1516cm -1 It is the C-F absorption peak.

[0050] (2) 20 par...

Embodiment 3

[0054] A preparation method of a fluorine-containing superhydrophobic porous material for oil-water separation, the steps are as follows:

[0055] (1) Mix 100 parts by weight of hexachlorocyclotriphosphazene, 300 parts by weight of bisphenol A, and 25,000 parts by weight of toluene, ultrasonicate at 30 Hz, react at 60°C for 15 minutes, add 10 parts by weight of pyridine, and react ultrasonically at 65°C 2 hours. The obtained product was washed with acetone, ethanol and deionized water respectively, centrifuged three times, and dried at 80° C. for 3 hours to finally obtain polyphosphazene microspheres.

[0056] (2) 50 parts by weight of styrene, 20 parts by weight of perfluorohexyl ethyl methacrylate, 20 parts by weight of polyphosphazene microspheres, 50 parts by weight of pentaerythritol triacrylate, 10 parts by weight of cuprous naphthenate / peroxide Dibenzoyl and 30 parts by weight of Span40 were ultrasonically dispersed at 40 Hz for 5 minutes to obtain a mixed system.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com