High-activity aluminum oxide three-dimensional electrode particle filler as well as preparation method and application thereof

A technology of three-dimensional electrodes and alumina, which is applied in chemical instruments and methods, wastewater treatment in processing, and special treatment targets, etc., can solve problems such as agglomeration and loss of active components, achieve simple preparation process, reduce preparation cost, and repeat The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

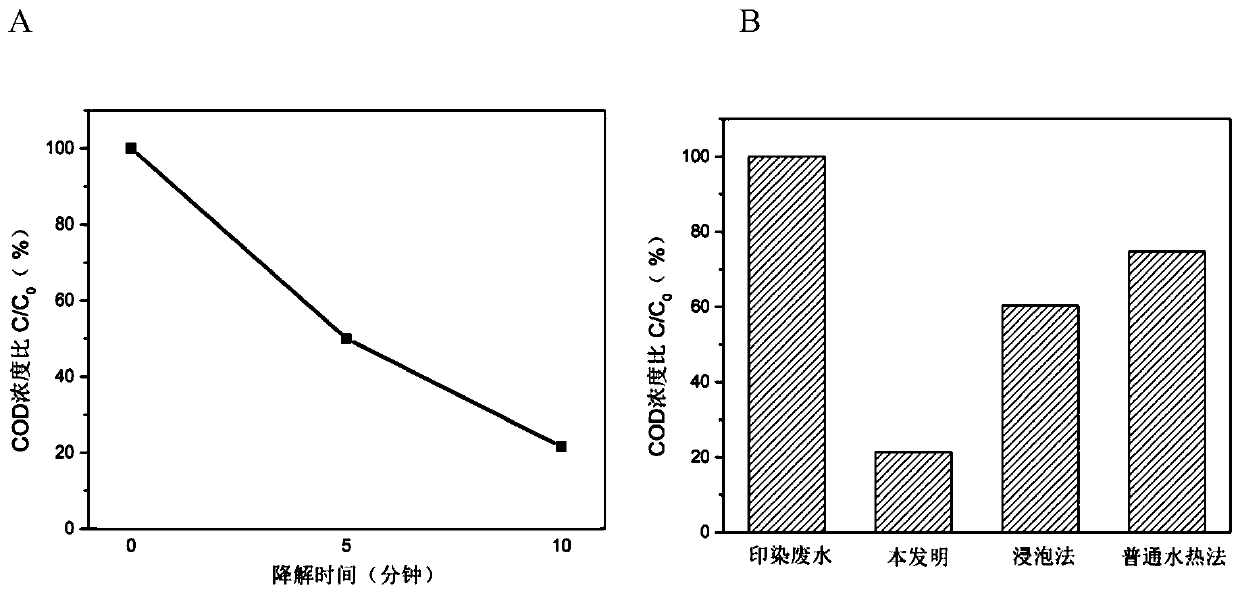

Embodiment 1

[0028] The preparation method of a highly active alumina three-dimensional electrode particle filler in this embodiment comprises the following steps:

[0029] (1) Alumina carrier pretreatment: the γ-Al 2 o 3 After washing with deionized water, dry at 100°C for 12 hours, and set aside;

[0030] (2) Microwave pretreatment: Weigh 5.9g glucose, 1.2g nickel acetate tetrahydrate, 3.0g copper acetate monohydrate and 0.95g cobalt acetate tetrahydrate, place in 40mL 10% v / v dilute nitric acid, heat to dissolve at 80°C, Then add the γ-Al after step (1) pretreatment 2 o 3 20g, microwave hydrothermal reaction at 170°C for 20min; after the reaction, dry at 100°C to obtain the pretreated particle filler;

[0031] (3) Quartz sand roasting: put the pretreated particle filler obtained in step (2) into a crucible, cover the surface with a layer of quartz sand, roast in a muffle furnace at 800°C for 4 hours, and remove it after cooling to room temperature. Quartz sand is used to obtain hi...

Embodiment 2

[0034]The preparation method of a highly active alumina three-dimensional electrode particle filler in this embodiment comprises the following steps:

[0035] (1) Alumina carrier pretreatment: the γ-Al 2 o 3 After washing with deionized water, dry at 100°C for 12 hours, and set aside;

[0036] (2) Microwave pretreatment: Weigh 3.0g glucose, 1.2g nickel acetate tetrahydrate, 3.0g copper acetate monohydrate and 0.95g cobalt acetate tetrahydrate, place in 40mL 10% v / v dilute nitric acid, heat to dissolve at 80°C, Then add the γ-Al after step (1) pretreatment 2 o 3 20g, microwave hydrothermal reaction at 170°C for 20min; after the reaction, dry at 100°C to obtain the pretreated particle filler;

[0037] (3) Quartz sand roasting: put the pretreated particle filler obtained in step (2) into a crucible, cover the surface with a layer of quartz sand, and roast in a muffle furnace at 800°C for 4 hours, and remove the quartz after cooling to room temperature. sand to obtain highly...

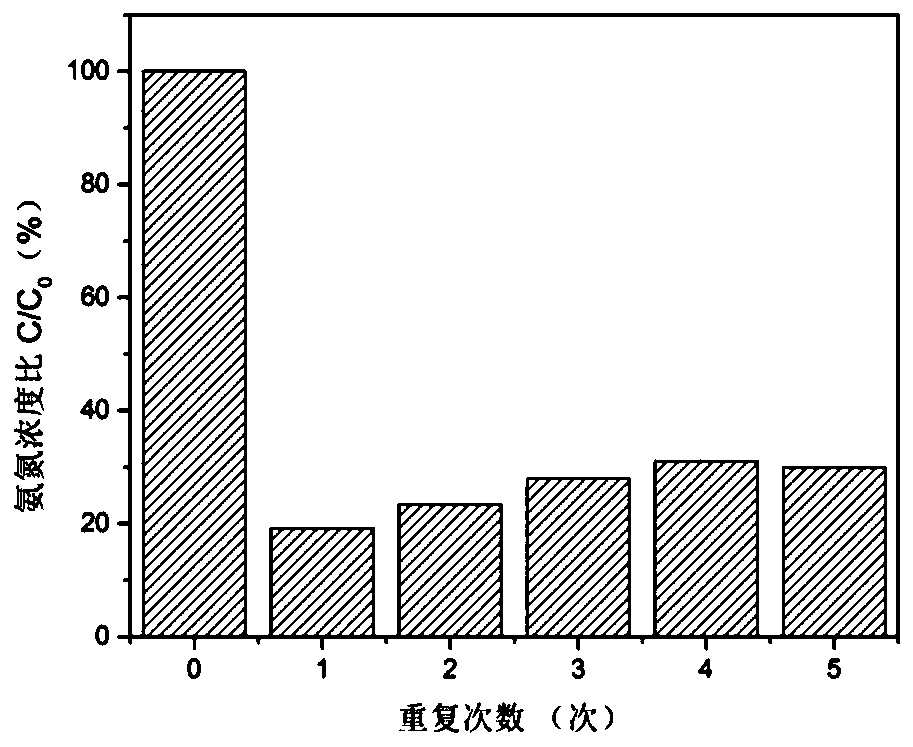

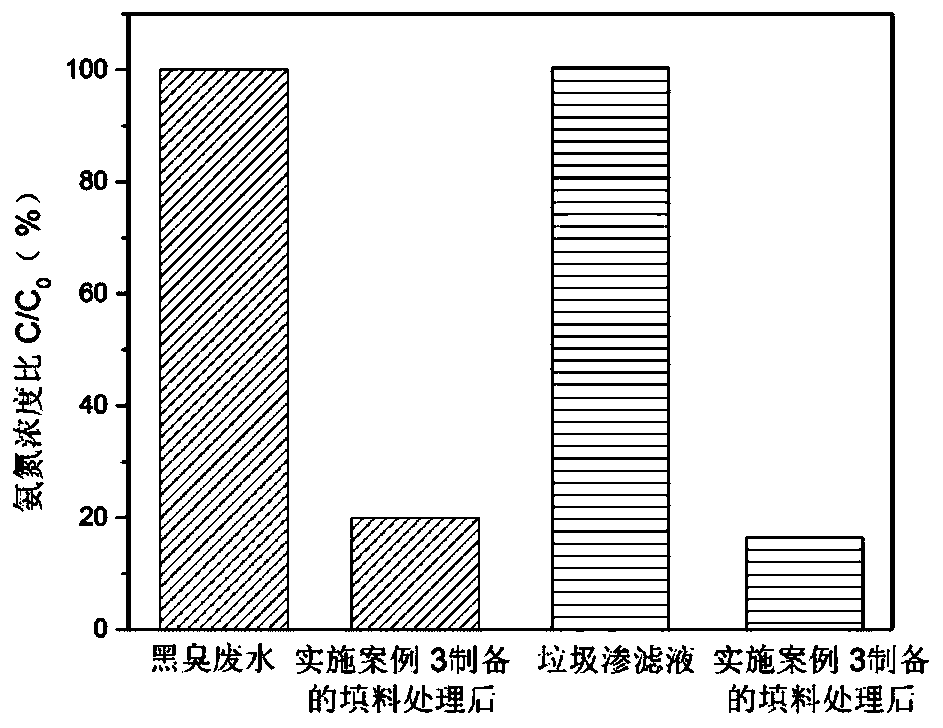

Embodiment 3

[0045] The preparation method of a highly active alumina three-dimensional electrode particle filler in this embodiment comprises the following steps:

[0046] (1) Alumina carrier pretreatment: the γ-Al 2 o 3 After washing with deionized water, dry at 100°C for 12 hours;

[0047] (2) Microwave pretreatment: Weigh 5.9g glucose, 2.4g nickel acetate tetrahydrate, 6.0g copper acetate monohydrate and 1.9g cobalt acetate tetrahydrate, place in 40mL 10% v / v dilute nitric acid, heat to dissolve at 80°C, Then add the γ-Al after step (1) pretreatment 2 o 3 20g, microwave hydrothermal reaction at 170°C for 20min; after the reaction, dry at 100°C;

[0048] (3) Quartz sand roasting: the pretreated particle filler obtained in step (2) is packed into a crucible, the surface is covered with a layer of quartz sand, roasted at 600° C. for 4 hours, and the quartz sand is removed after being cooled to room temperature to obtain high Activated alumina three-dimensional electrode particle fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com