Preparation method of rare earth substituted yttrium iron garnet crystal

A technology for yttrium iron garnet and crystal is applied in the field of preparation of rare earth substituted yttrium iron garnet crystal, and achieves the effects of promoting growth and growth, reducing growth difficulty and energy consumption cost, and promoting the development of industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

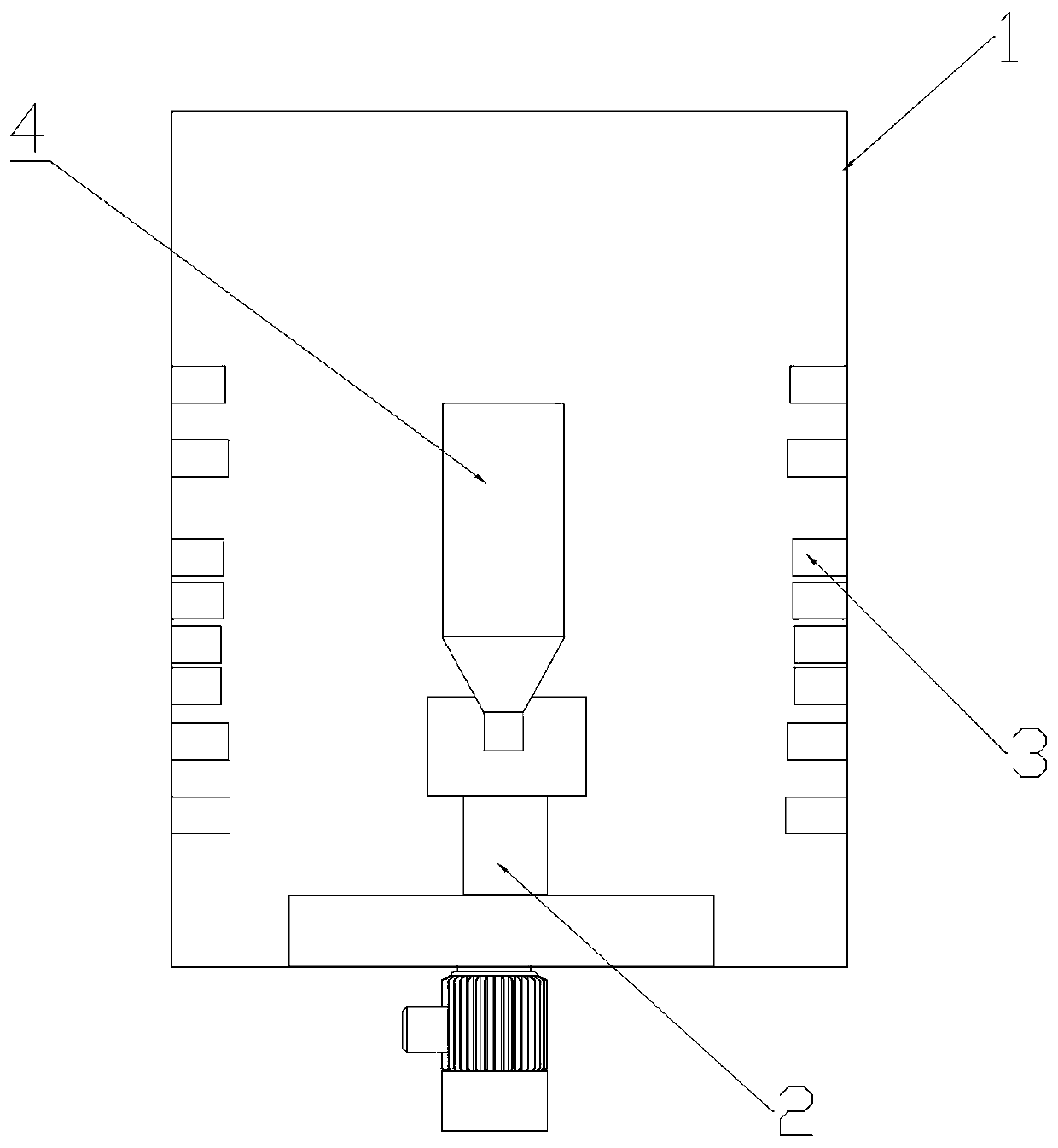

Image

Examples

Embodiment 1

[0029] A preparation method for ytterbium-substituted yttrium-iron garnet crystals, comprising the following steps:

[0030] (1) According to the crystal molecular formula Y (3-x) Yb x Fe 5 o 12 , where x=0.45, weigh Y with a purity ≥99.99% according to the molar ratio 2 o 3 , Yb 2 o 3 and Fe 2 o 3 raw materials, and mixed and stirred various weighed raw materials for 30-50 minutes to obtain mixed powder raw materials; after the mixed powder raw materials were pressed into blocks, they were placed in a solid state reaction at a temperature of 1100 ° C for 12 hours to obtain polycrystalline blocks ;

[0031] (2) Crushing and grinding the polycrystalline material block obtained in step (1), adding a flux and placing it in an agate mortar for full grinding until uniform to obtain a mixed material; the flux is Bi 2 o 3 +B 2 o 3 Main composite flux, its raw material purity is 99.999%, which accounts for 58% of the total mass of the mixed material;

[0032] (3) Select ...

Embodiment 2

[0038] A preparation method of yttrium iron garnet crystal, comprising the following steps:

[0039] (1) According to the crystal molecular formula Y 3 Fe 5 o 12 , weigh Y with a purity ≥99.99% according to the molar ratio 2 o 3 and Fe 2 o 3 raw materials, and put the weighed various raw materials in an agate mortar and grind them fully until they are uniform to obtain the mixed powder raw materials; after the mixed powder raw materials are pressed into blocks, they are placed at a temperature of 1150°C for solid phase reaction for 20 hours, Obtain a polycrystalline block;

[0040] (2) Crushing and grinding the polycrystalline block obtained in step (1), and adding a flux to grind for 40-60 minutes to obtain a mixed material; the flux is Bi 2 o 3 +B 2 o 3 Main composite flux, its raw material purity is 99.999%, which accounts for 64% of the total mass of the mixed material;

[0041] (3) Put the mixed material obtained in step (2) into the crucible and seal it; put t...

Embodiment 3

[0047] A method for preparing terbium-substituted yttrium-iron garnet crystals, comprising the following steps:

[0048] (1) According to the crystal molecular formula Y (3-x) Tb x Fe 5 o 12 , where x=1.25, weigh Y with a purity ≥99.99% according to the molar ratio 2 o 3 , Tb 2 o 3 and Fe 2 o 3 Raw materials, put the weighed raw materials in an agate mortar and grind them until they are uniform for 30-50 minutes to obtain the mixed powder raw materials; after the mixed powder raw materials are pressed into blocks, they are placed in a solid phase at a temperature of 1300°C Reaction 10h, obtain polycrystalline block;

[0049] (2) Crushing and grinding the polycrystalline material block obtained in step (1), adding a flux and placing it in an agate mortar for full grinding until uniform to obtain a mixed material; the flux is Bi 2 o 3 +B 2 o 3 Main composite flux, its raw material purity is 99.999%, which accounts for 50% of the total mass of the mixed material;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com