Method for preparing cerium doped yttrium aluminum garnet

A technology doped with yttrium aluminum garnet and cerium, which is applied in chemical instruments and methods, alumina/aluminum hydroxide, luminescent materials, etc., can solve the problems of increased production and synthesis costs, harsh synthesis conditions, and complicated preparation processes, and achieves Small impurity phase, low synthesis temperature, and good particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Mix 2.4557g of yttrium oxide and 10mL of concentrated nitric acid in a closed reaction kettle, heat to 120°C under magnetic stirring, and keep the temperature for 10 minutes. Dissolve 15.4574g of aluminum nitrate and 0.3257g of cerium nitrate in 30mL of deionized water, add 3.6g of urea as a combustion agent, and add 0.8g of polyethylene glycol as an organic dispersant.

[0028] After mixing the two solutions, place them in a high-temperature sintering furnace with an air atmosphere at 800°C for 10 minutes. After a vigorous reaction, grind the resulting yellow powder and place it at 1100°C (the heating rate is 300°C per hour) with hydrogen and The sintering was carried out for 5 hours in a reducing atmosphere mixed with nitrogen 4:96. Cool the obtained sample to room temperature, wash with acid and alcohol, and sieve through a 400-mesh sieve to obtain YAG: Ce 3+ Powder.

example 2

[0030] Mix 2.4952g of yttrium oxide with 10mL of concentrated nitric acid with a mass fraction of 67% in a closed reaction kettle, heat to 140°C under magnetic stirring, and keep the temperature for 5 minutes. Dissolve 14.0674g of aluminum nitrate and 0.2605g of cerium nitrate in 30mL of deionized water, add 1.8g of urea as a combustion agent, and add 0.5g of polyethylene glycol as an organic dispersant.

[0031] After mixing the two solutions, place them in a high-temperature sintering furnace with an air atmosphere at 700°C for 5 minutes. After a vigorous reaction, grind the resulting yellow powder and place it at 900°C (the heating rate is 300°C per hour) with hydrogen and The sintering was carried out in a reducing atmosphere mixed with nitrogen 4:96 for 3 hours. Cool the obtained sample to room temperature, wash with acid and alcohol, and sieve through a 400-mesh sieve to obtain YAG: Ce 3+ Powder.

example 3

[0033] Mix 2.4133g of yttrium oxide with 10mL of concentrated nitric acid with a mass fraction of 67% in a closed reaction kettle, heat to 120°C under magnetic stirring, and keep the temperature for 5 minutes. Dissolve 14.0674g of aluminum nitrate and 0.6741g of cerium nitrate in 30mL of deionized water, add 5.4g of urea as a combustion agent, and add 1.2g of polyethylene glycol as an organic dispersant.

[0034] After mixing the two solutions, place them in a high-temperature sintering furnace with an air atmosphere at 900°C for 15 minutes. After a vigorous reaction, grind the resulting yellow powder and place it at 1300°C (the heating rate is 300°C per hour) with hydrogen and The sintering was carried out in a reducing atmosphere mixed with nitrogen 4:96 for 6 hours. The obtained sample was cooled to room temperature, washed with acid and alcohol, and sieved through a 400-mesh sieve to obtain YAG: Ce 3+ Powder.

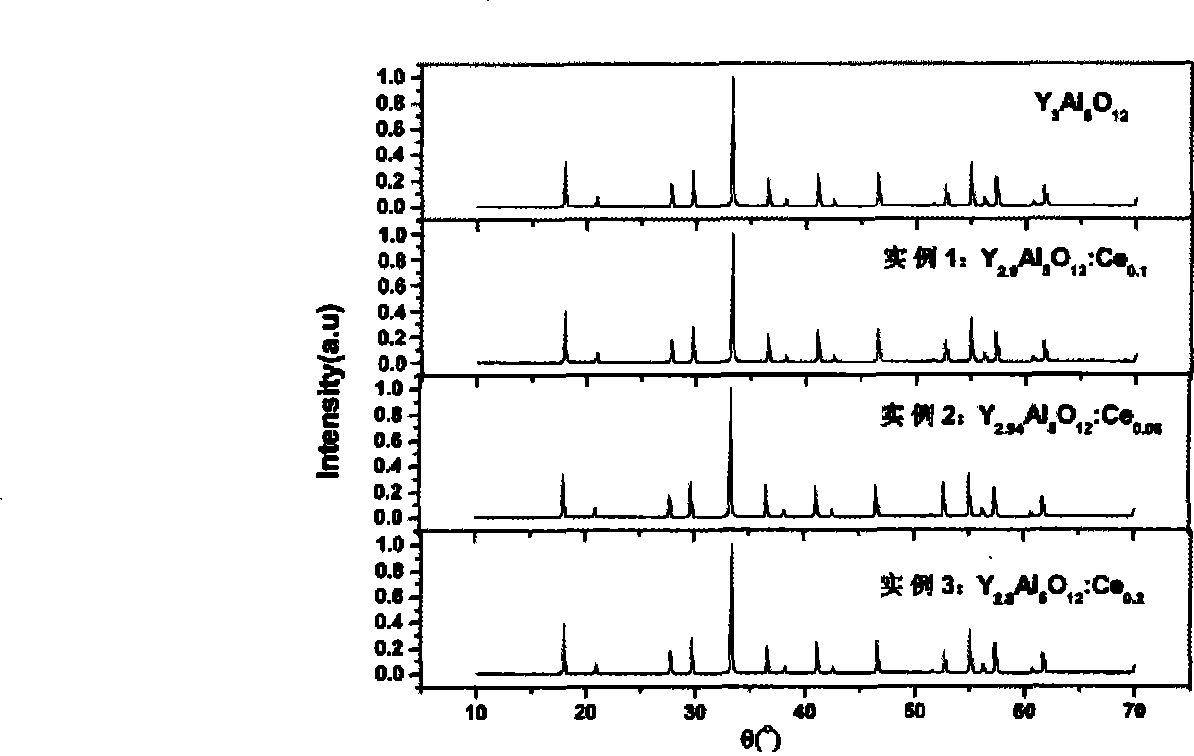

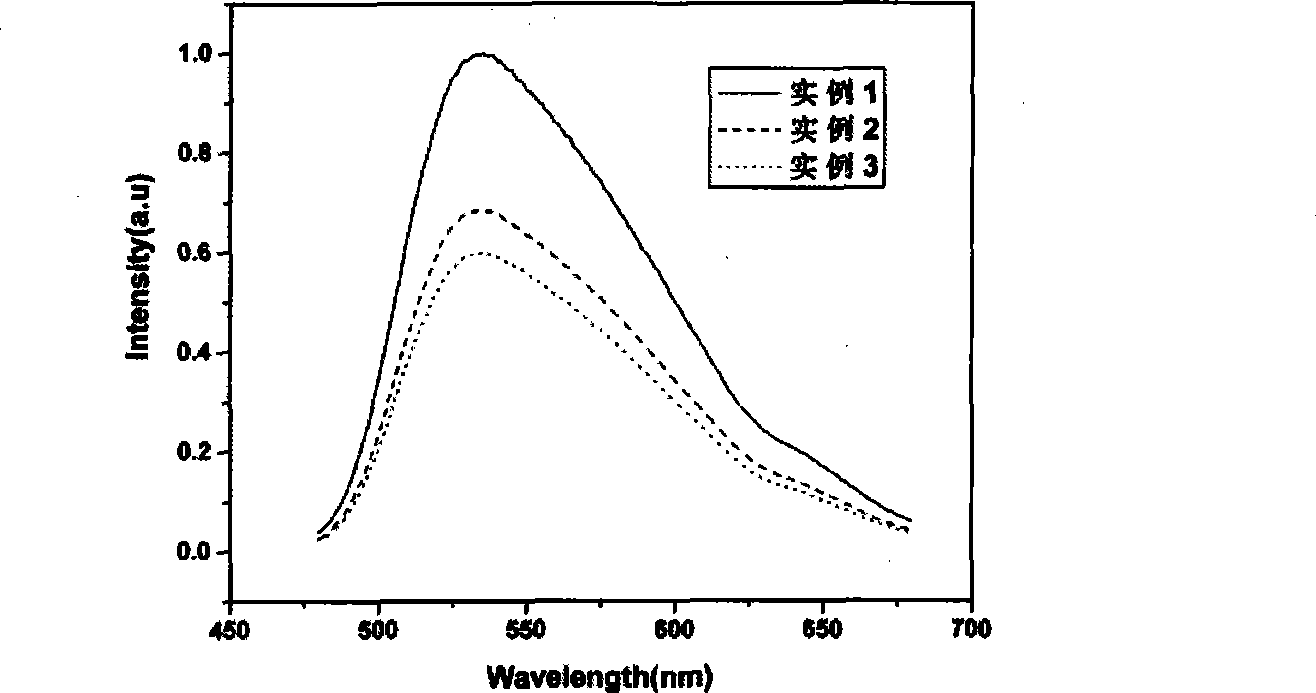

[0035] attached by figure 1 It can be seen that the doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com