Light flexible paper-based 1T-phase tungsten disulfide/carbon nanotube composite thermoelectric material and preparation method thereof

A carbon nanotube composite, tungsten disulfide technology, applied in the direction of thermoelectric device node lead-out material, thermoelectric device manufacturing/processing, etc., can solve problems such as unfavorable ZT value, low conductivity, etc. The effect of reducing thermal conductivity and increasing the Seebeck coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

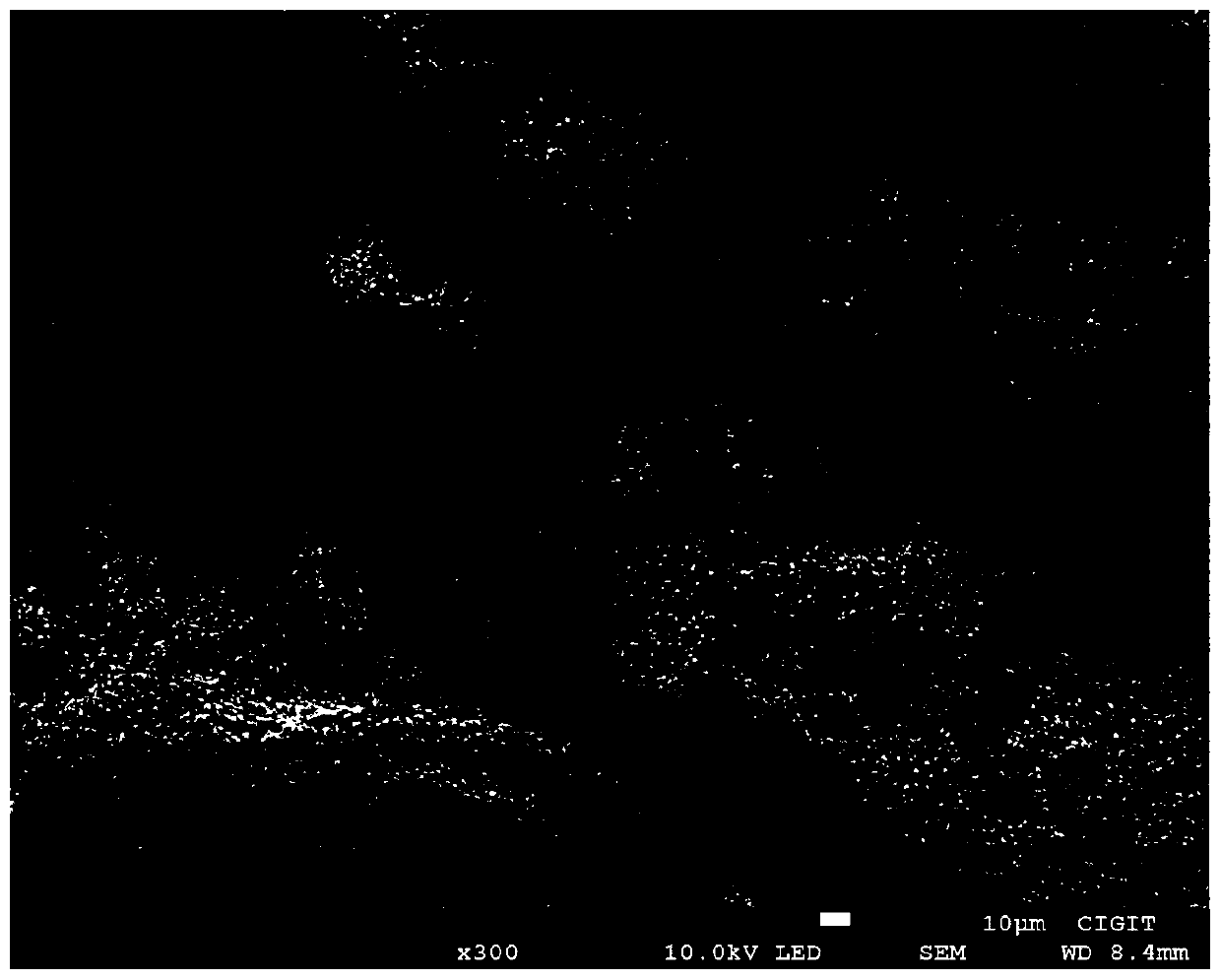

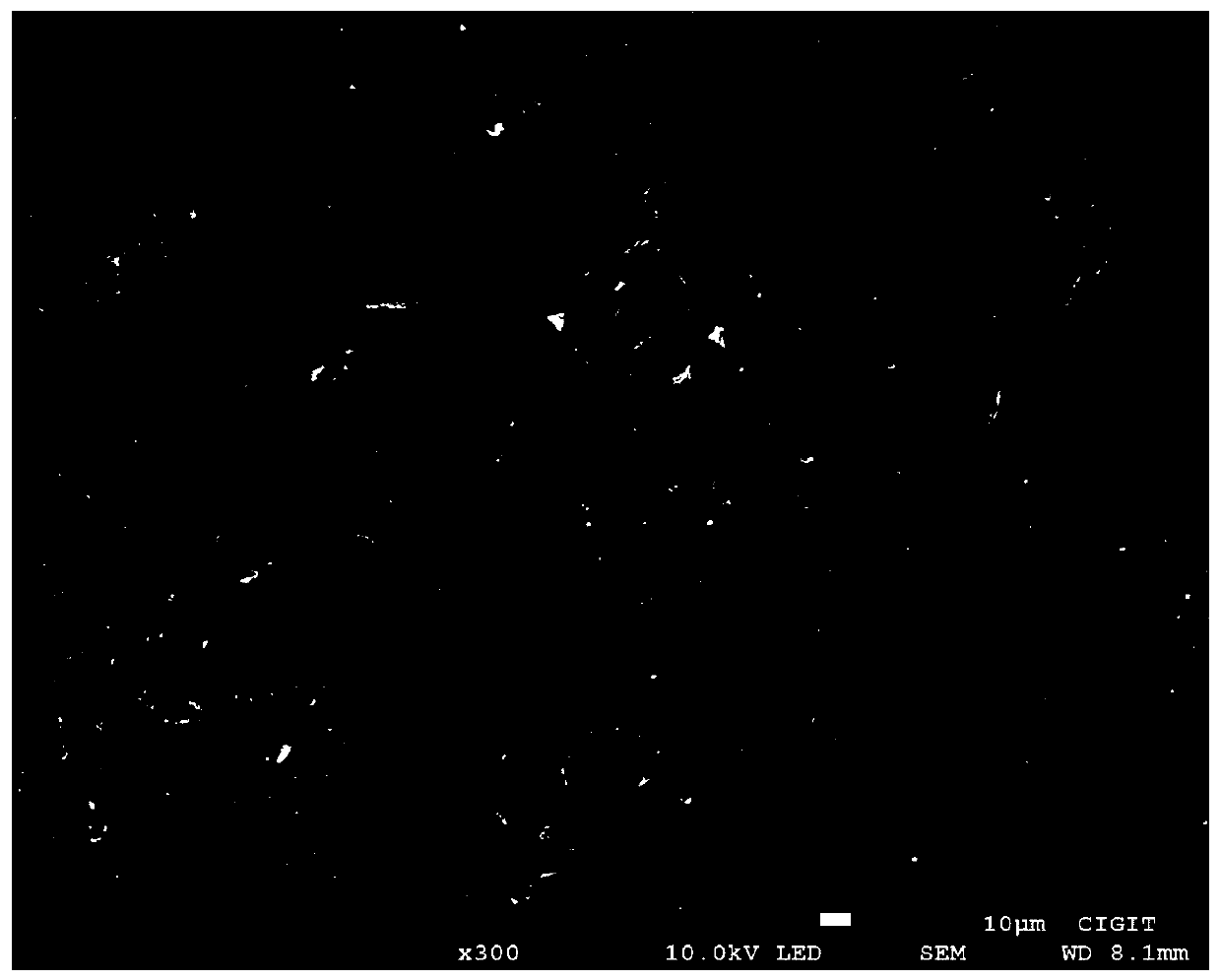

Image

Examples

Embodiment 1

[0039] A method for preparing a lightweight flexible cellulose paper-based 1T phase tungsten disulfide / carbon nanotube composite thermoelectric material, characterized in that it comprises the following steps:

[0040] (1) 15mg of single-walled carbon nanotube powder is added to 30ml of sodium dodecylbenzenesulfonate aqueous solution (concentration is 1%), and ultrasonic dispersion is carried out by an ultrasonic cell breaker to obtain a stable dispersion of carbon nanotubes in water liquid;

[0041] Dissolve 0.8g of ammonium metatungstate hydrate and 0.8g of thiourea in 30ml of water, stir magnetically at room temperature until completely dissolved, then add 0.28g of oxalic acid dihydrate and stir vigorously until completely dissolved;

[0042] (2) Mix the above two solutions, stir at room temperature for 15 minutes, then transfer to a 100ml reactor lined with polytetrafluoroethylene, and react at 220°C for 24 hours; after the reaction, the reactor is naturally After cooling...

Embodiment 2

[0051] A method for preparing a lightweight flexible cellulose paper-based 1T phase tungsten disulfide / carbon nanotube composite thermoelectric material, characterized in that it comprises the following steps:

[0052] (1) Add 15 mg of single-walled carbon nanotube powder to 30 ml of cetyltrimethylammonium bromide aqueous solution (concentration is 0.5%), and carry out ultrasonic dispersion by an ultrasonic cell disruptor to obtain stably dispersed carbon nanotubes water dispersion;

[0053] Dissolve 0.8g of ammonium metatungstate hydrate and 0.8g of thiourea in 30ml of water, stir magnetically at room temperature until completely dissolved, then add 0.28g of oxalic acid dihydrate and stir vigorously until completely dissolved;

[0054] (2) Mix the above two solutions, stir at room temperature for 15 minutes, then transfer to a 100ml reactor lined with polytetrafluoroethylene, and react at 220°C for 24 hours; after the reaction, the reactor is naturally After cooling to room ...

Embodiment 3

[0063] A method for preparing a lightweight flexible cellulose paper-based 1T phase tungsten disulfide / carbon nanotube composite thermoelectric material, characterized in that it comprises the following steps:

[0064] (1) 15 mg of single-walled carbon nanotube powder is added to 30 ml of Triton X-100 aqueous solution (concentration is 2%), and ultrasonically dispersed by an ultrasonic cell disruptor to obtain a stably dispersed carbon nanotube aqueous dispersion;

[0065] Dissolve 0.8g of ammonium metatungstate hydrate and 0.8g of thiourea in 30ml of water, stir magnetically at room temperature until completely dissolved, then add 0.28g of oxalic acid dihydrate and stir vigorously until completely dissolved;

[0066] (2) Mix the above two solutions, stir at room temperature for 15 minutes, then transfer to a 100ml reactor lined with polytetrafluoroethylene, and react at 220°C for 24 hours; after the reaction, the reactor is naturally After cooling to room temperature, the obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com