Transition metal nano oxidase, preparation method, water treatment device and application

A water treatment device and transition metal technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult surface water treatment, limited removal rate of water-soluble humus, etc., and achieve the production cost Low, reduced chemical and energy costs, strong acid and alkali resistance and environmental stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Preparation:

[0052] (1) Heat the Prussian blue in a tube furnace under nitrogen protection, control the gas flow rate / precursor mass to 100mL / min g, heat up at 2°C / min, keep at 600°C for 6h, and cool down naturally;

[0053] (2) Washing away unstable Fe with sulfuric acid with a mass fraction of 0.5%, washing with water until neutral, and then drying to obtain transition metal nano-oxidase.

[0054] Carry out magnetic separation to above-mentioned transition metal nanooxidase, the result is as follows figure 1 shown.

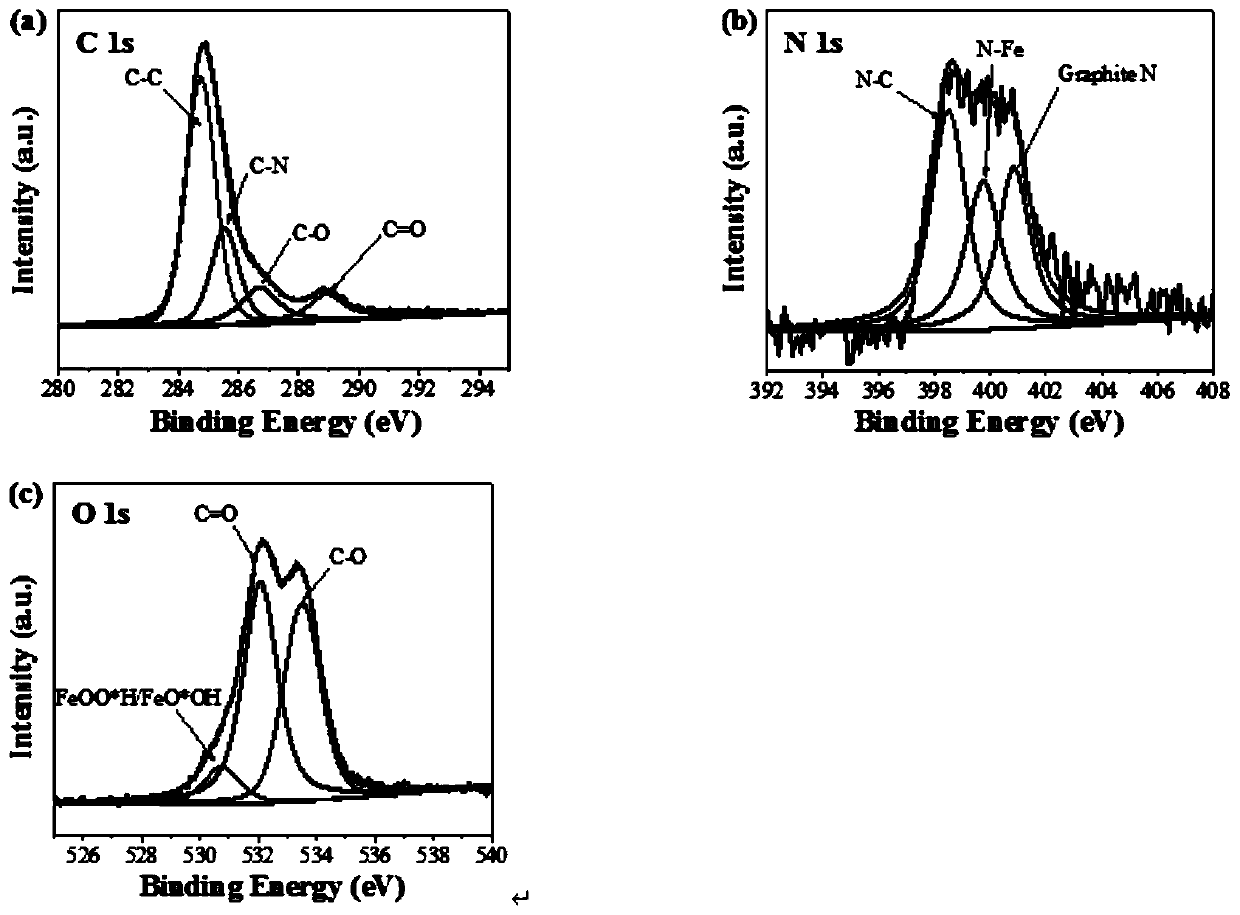

[0055] Carry out XPS characterization to above-mentioned transition metal nanooxidase, the result is as follows figure 2 shown;

[0056] figure 2 XPS C 1s in (a) can observe the characteristic peak of -C-O / -C=O structure;

[0057] figure 2 (b) The characteristic peaks of the N-Fe structure can be observed in the N1s image;

[0058] figure 2 The characteristic peaks of FeOO*H and FeO*OH active structures can be observed in the O1s image in (c...

Embodiment 2

[0063] (1) Heat Prussian blue in a tube furnace, use a mixture of oxygen and nitrogen with an oxygen content of 0.02% as a protective gas, control the gas flow rate / precursor mass to 100mL / min g, and heat up at 2°C / min, Keep warm at 600°C for 6 hours, then cool down naturally;

[0064] (2) Washing away unstable Fe with sulfuric acid with a mass fraction of 0.5%, washing with water until neutral, and then drying to obtain transition metal nano-oxidase.

[0065] The above-mentioned Prussian blue precursor can be replaced by a metal organic framework material containing one or more elements of Fe, Co, Cu, Mn, Zn, Ni, Ti, Zr, and Mo.

Embodiment 3

[0067] Preparation:

[0068] (1) Mix melamine: iron trichloride in a mass ratio of 2:1, dissolve in methanol and evaporate to dryness to obtain a melamine precursor;

[0069] (2) Heat the precursor in a tube furnace, under the protection of nitrogen, control the gas flow rate / precursor mass to 200mL / min g, heat up at 5°C / min, keep at 800°C for 3h, and cool down naturally;

[0070] (3) washing the unstable Fe with a mixed acid of nitric acid and phosphoric acid with a mass fraction of 5% to remove the unstable Fe, washing with water until neutral, and then drying to obtain the transition metal nano-oxidase.

[0071] The above ferric chloride can be replaced by any one or several soluble metal salts of Co, Cu, Mn, Zn, Ni, Ti, Zr, Mo, so as to obtain the nano-oxidase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com