Porous silicon dioxide double-spherical-shell hollow composite microsphere as well as preparation method and application thereof

A technology of porous silica and composite microspheres, which is applied in the field of powder materials, can solve the problems of separation, recovery and recycling, weak interfacial force, and independent nucleation, etc., and achieve the improvement of independent nucleation and strong acid Alkali resistance, effect of avoiding deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

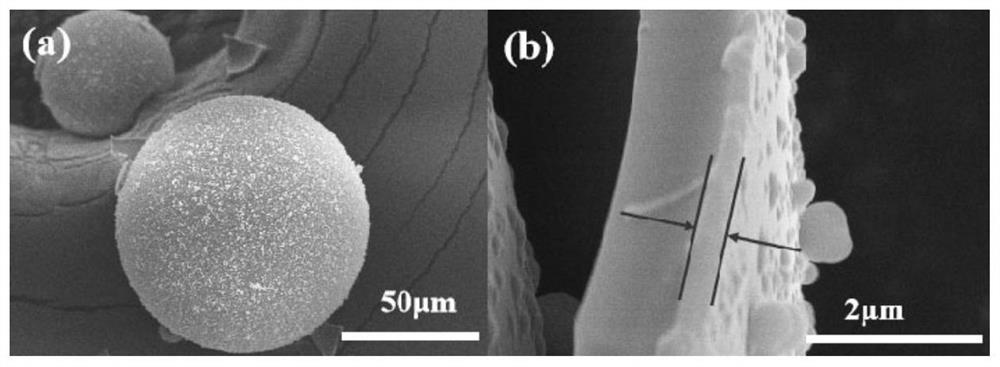

[0060] A method for preparing porous silica double-shell hollow composite microspheres, comprising the steps of:

[0061] The first step is surface treatment of hollow glass microspheres. Mix 10mL 3-aminopropyltriethoxysilane coupling agent with 150mL distilled water, stir for 10min; add 150mL absolute ethanol, then add 15g glass beads (0.3-0.5g / cm 3 ), stirred for 30 min, suction filtered, washed with ethanol, and dried at 80°C.

[0062] The second step is the coating experiment. First weigh 2g of CTAB into a single-necked flask, add 80ml of distilled water, stir in a 50°C water bath, dissolve until the solution is transparent, and remove from the water bath. Then, add 100ml of absolute ethanol and 5g of the hollow glass microspheres obtained in the first step to the single-necked flask containing the CTAB solution, and stir to mix. Add 10ml of concentrated ammonia water and 0.03g of sodium chloride to the above mixed solution, and stir for 10min. Finally, the mixed solut...

Embodiment 2

[0068] The pretreatment steps were the same as in Example 1, except that the mass of the hollow glass microspheres obtained in the first step was added to be 10 g, and the rest of the conditions remained unchanged to prepare porous silica double-shell hollow composite microspheres.

Embodiment 3

[0070] The pretreatment steps were the same as in Example 1, except that the mass of CTAB added was 3 g, and the rest of the conditions remained unchanged, and porous silica double-shell hollow composite microspheres were prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com