Preparation method of low-temperature sintered alumina ceramic membrane

An alumina ceramic membrane and low-temperature sintering technology, which is applied in the fields of inorganic ceramic porous materials and inorganic ceramic separation membrane materials, can solve the problems of high sintering temperature of alumina ceramic membrane, high manufacturing cost and investment cost, and achieves simplified sintering process and high production cost. The effect of low cost and investment cost and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

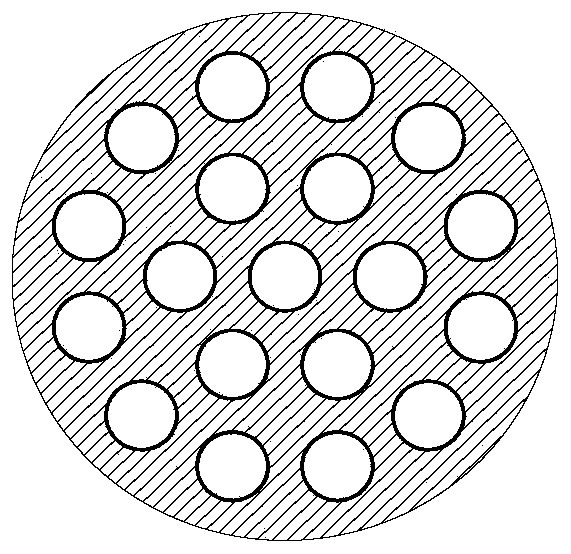

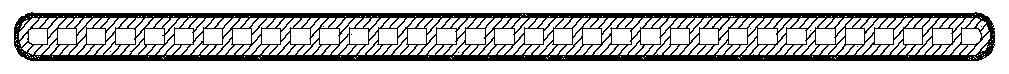

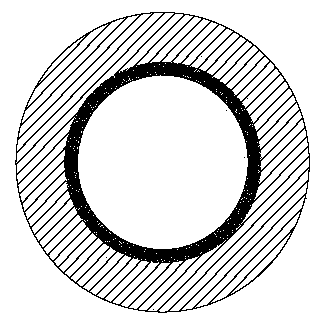

[0031] 85% α-Al with a medium particle size of 5 μm 2 o 3 powder, 15% sintering aids (35% kaolin, 20% magnesium oxide, 10% calcium carbonate, 20% silicon micropowder, 10% borosilicate glass powder and 5% water glass), 5.5% hydroxypropyl methylcellulose (Viscosity 100,000) 6% graphite powder (5000 mesh), 6% oleic acid and 22% water (including 2‰ polyacrylic acid dissolved in water), mixed in a strong mixer for 40 minutes; then kneaded in a kneader for 30 minutes ;After refining the mud on the rough mud machine for 1 to 3 times, practice the mud again under a vacuum degree of not less than -0.095MPa; stale for 24 hours at a temperature of 20-25°C and a humidity of 50-80%; and then again in a vacuum degree of not less than -0.095MPa; The mud is drilled once at 0.095MPa; the tubular alumina support with multiple channels is extruded on the extruder with a vacuum degree of not less than -0.095MPa, the outer diameter of the support is 30mm, 19 channels, and the channel diameter is ...

Embodiment 2

[0034] Only the firing temperature of the film layer was changed to 1100° C., and the other operation steps, addition amount and control parameters were the same as in Example 1.

Embodiment 3

[0036] Only the firing temperature of the film layer was changed to 1120° C., and the other operation steps, addition amount and control parameters were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com