Method of separating N-methyl pyrrolidone from massive chloroform systems

A methyl pyrrolidone and its separation technology, applied in the field of fine chemistry, can solve problems such as partial acidity, accelerated NMP decomposition, deterioration, corrosion of equipment, etc., to improve separation efficiency and product recovery rate, prevent NMP decomposition, and prolong equipment life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

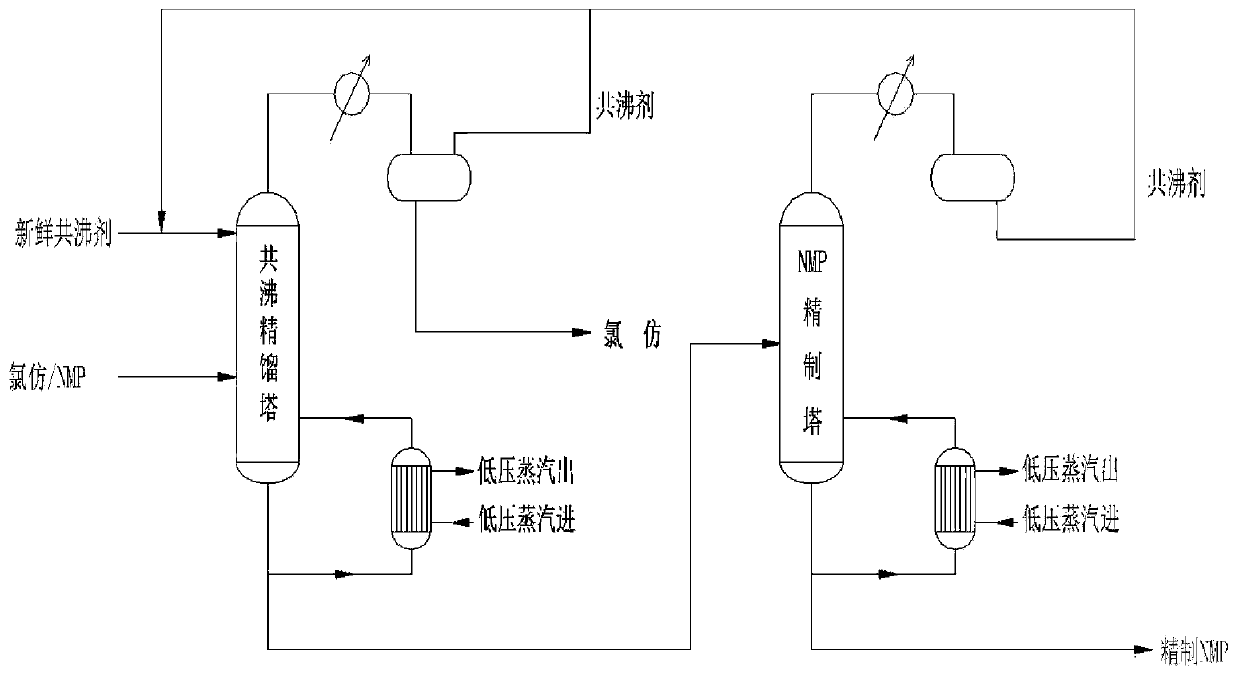

Image

Examples

Embodiment 1

[0019] A kind of method for separating N-methylpyrrolidone from a large amount of chloroform system, concrete steps are as follows:

[0020] Get the chloroform system containing 8% NMP and transport it to the middle part of the azeotropic rectification tower, and deliver the entrainer to the first layer plate of the azeotropic rectification tower according to 7% of the chloroform mass in the above-mentioned system at the same time, utilize the entrainer water and chloroform The principle of forming the lowest azeotrope, the lowest azeotrope is distilled to the top of the tower, condensed to the reflux tank, and then the chloroform and the azeotropic agent are not dissolved and separated, and the upper layer of the top reflux tank is the azeotropic agent, and the lower layer is chloroform. The entrainer returns to the entrainer inlet of the azeotropic rectification column to continue recycling, and the chloroform is extracted. Control the operating pressure of the entrainer rec...

Embodiment 2

[0022] A kind of method for separating N-methylpyrrolidone from a large amount of chloroform system, concrete steps are as follows:

[0023] Get the chloroform system that contains 7%NMP and deliver to the middle part of the azeotropic rectification tower, transport the entrainer to the first floor plate of the azeotrope rectification tower by 15% of the chloroform quality in the above-mentioned system, utilize the entrainer water / ethanol ( 9:1) The principle of forming the lowest azeotrope with chloroform, the lowest azeotrope is distilled to the top of the tower, condensed to the reflux tank, and then the chloroform and the azeotropic agent do not dissolve each other, layered, and the upper layer of the top reflux tank is azeotropic agent, the lower floor is chloroform, and the entrainer returns to the entrainer inlet of the azeotropic rectification tower to continue recycling, and the chloroform is extracted. Control the operating pressure of the entrainer rectification tow...

Embodiment 3

[0025] A kind of method for separating N-methylpyrrolidone from a large amount of chloroform system, concrete steps are as follows:

[0026] Get the chloroform system that contains 9%NMP and deliver to the middle part of the azeotropic rectification tower, transport the entrainer to the first floor plate of the azeotrope rectification tower by 10% of the chloroform quality in the above-mentioned system, utilize the entrainer water / methanol ( 9:1) The principle of forming the lowest azeotrope with chloroform, the lowest azeotrope is distilled to the top of the tower, condensed to the reflux tank, and then the chloroform and the azeotropic agent do not dissolve each other, layered, and the upper layer of the top reflux tank is azeotropic agent, the lower floor is chloroform, and the entrainer returns to the entrainer inlet of the azeotropic rectification tower to continue recycling, and the chloroform is extracted. Control the operating pressure of the entrainer rectification to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com