Lithium ion battery cathode material and preparation method and application thereof

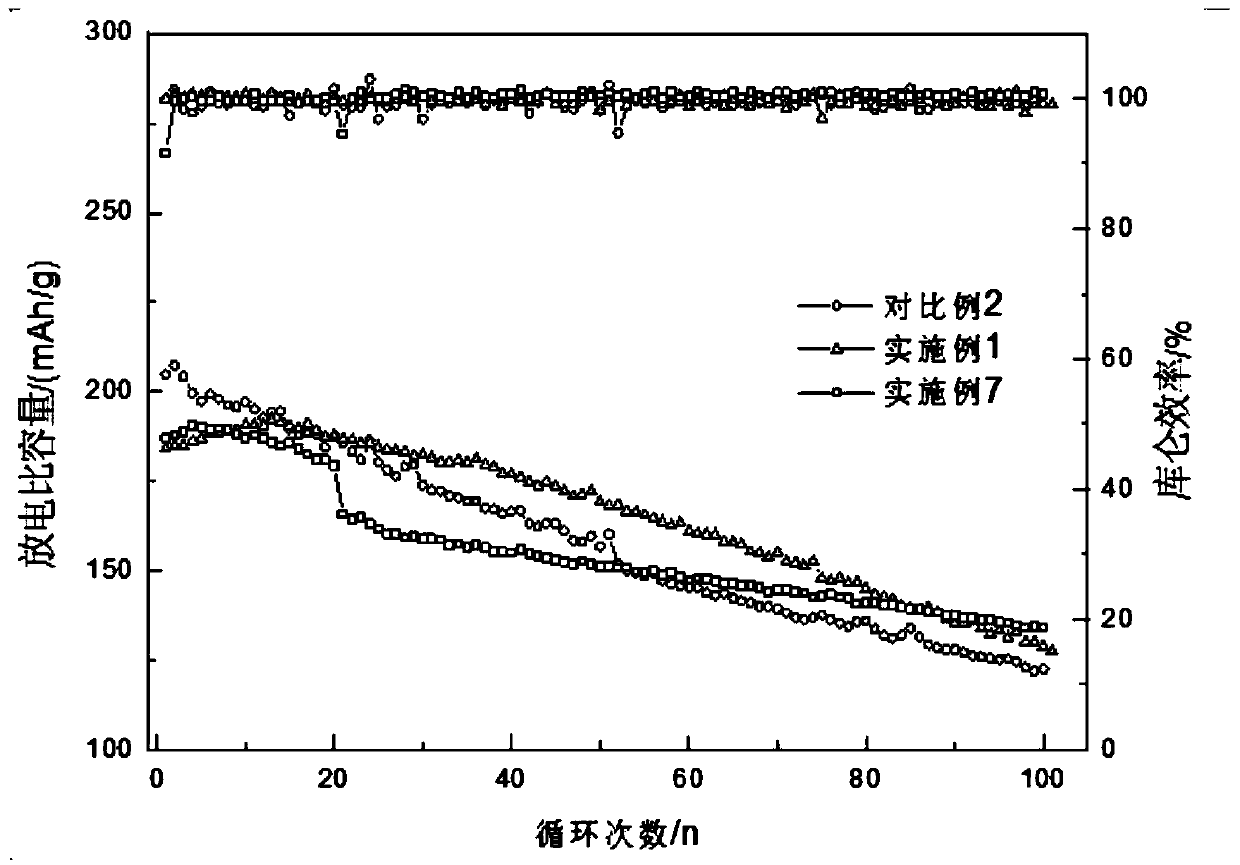

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as the impact of NCA materials on the electrochemical performance, achieve precise control of stoichiometric ratio, improve electrochemical performance, particle size Narrow distribution of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] A method for preparing a positive electrode material for a lithium-ion battery provided in an embodiment of the present invention includes:

[0085] The ternary precursor is obtained by hydrolyzing the metal alkoxide aluminum salt to coat the pseudo-boehmite layer on the surface of the nickel-cobalt binary precursor. The chemical formula of the binary precursor is Ni x co y (OH) 2 , where both x and y are greater than 0, and x+y=1;

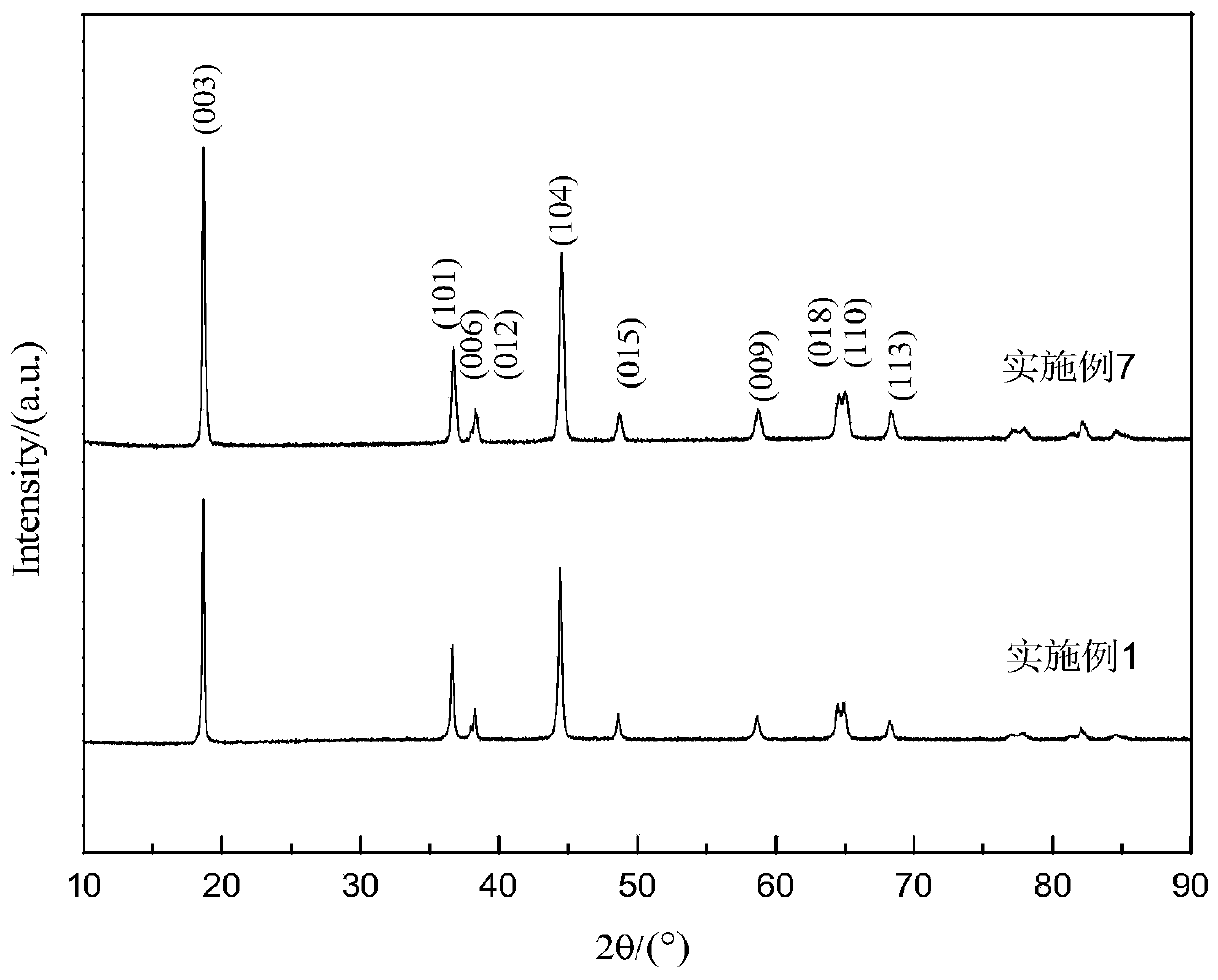

[0086] After mixing the ternary precursor and lithium salt evenly, sintering in an oxygen atmosphere to obtain LiNi a co b Al c o 2 , where a, b and c are all greater than 0, and a+b+c=1.

[0087] The reaction system of the metal alkoxide aluminum salt hydrolysis method is uniform, which is conducive to the growth of the crystal grains into a spherical shape, and the pseudo-boehmite is formed after the particles are agglomerated. The hydroxyl group produced by the adsorption of water on the surface of the binary precursor can provide...

Embodiment 1

[0129] Weigh 4.26g of aluminum isopropoxide, dissolve it in 50ml of absolute ethanol, and stir with a magnetic stirrer at room temperature at 1300rpm for 1.5h to obtain an aluminum isopropoxide solution. Then prepare 60ml of mixed reaction solvent, the volume ratio of water and absolute ethanol in the mixed reaction solvent is 1:1. The mixed reaction solvent was added to the first aluminum isopropoxide solution, and magnetic stirring was continued for 0.5 h to obtain an aluminum mixed solution. Weigh 36.6g Ni 0.928 co 0.072 (OH) 2 Add the powder into the aluminum mixed solution to obtain a mixed slurry, heat the slurry to 60°C, stir at 1000rpm for 4h to obtain a jelly, and then place the jelly in a drying oven for 24h at 80°C. Take 19.15g dry powder and 9.18g LiOH·H 2 O is evenly mixed, where Li:(Ni+Co+Al)=1.05:1 (molar ratio), sintered in stages in an atmosphere furnace filled with oxygen, first at 500°C for 5h, then at 700°C for 10h, and finally with The furnace was coo...

Embodiment 2

[0131] Weigh 4.26g of aluminum isopropoxide, dissolve it in 50ml of absolute ethanol, and stir with a magnetic stirrer at room temperature at 1300rpm for 1.0h to obtain an aluminum isopropoxide solution. Then prepare 60ml mixed reaction solvent, wherein the volume ratio of water and absolute ethanol is 1:1. Weigh 36.6g Ni 0.928 co 0.072 (OH) 2 The powder was added into the mixed reaction solvent, and the nickel-cobalt slurry was obtained after magnetic stirring for 0.5 h. Add the aluminum isopropoxide solution to the nickel-cobalt slurry to obtain a mixed slurry, stir while mixing, heat the mixed slurry to 60°C, stir at 1000rpm for 3.5h to obtain a jelly, and then place the jelly in Dry in a drying oven at 80°C for 24h. Take 19.15g dry powder and 9.18g LiOH·H 2 O is evenly mixed, where Li: (Ni+Co+Al) = 1.05:1 (molar ratio), sintered in stages in an atmosphere furnace filled with oxygen, first at 500°C for 5h, then at 700°C for 10h, and finally with the furnace Cool to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com