Novel solid-liquid battery with lithium metal negative electrode and high-voltage positive electrode

A lithium metal negative electrode, high voltage technology, applied in the manufacture of lithium batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc., can solve the problems of lithium metal cycle life limitation, poor solid-solid interface compatibility, and lower battery energy density. Excellent voltage resistance and charge-discharge cycle performance, reducing the probability of burning or even explosion, and reducing the effect of surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

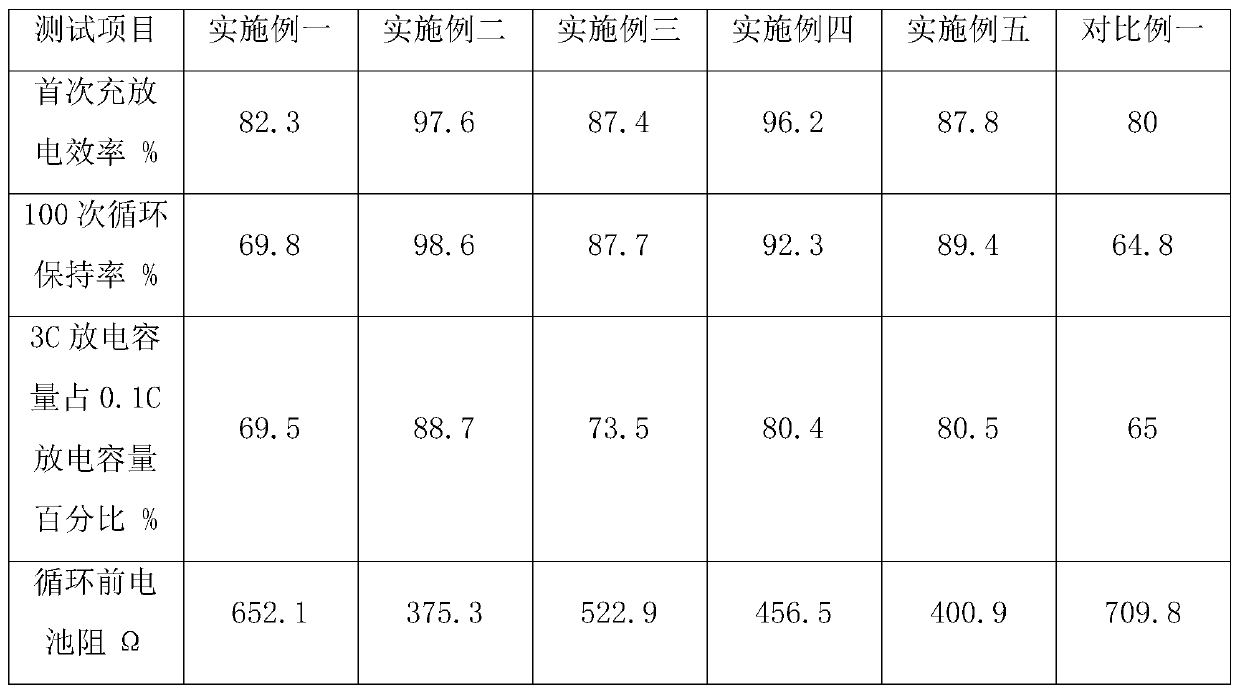

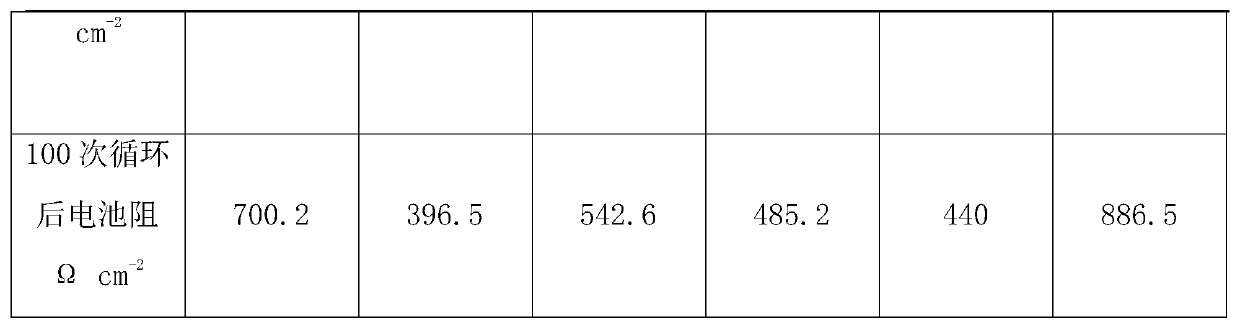

Embodiment 1

[0030] A method for preparing a novel solid-liquid battery with a lithium metal negative extremely high-voltage positive electrode, comprising the following steps:

[0031] Step 1. Coating lithium metal on the copper foil, and then placing the copper foil with lithium metal in a nitrogen atmosphere for 7 hours, and the temperature of the nitrogen gas is 45°C, and the flow rate is 4m / s, and finally the negative electrode sheet is obtained ;

[0032] Step two, LiNi 0.8 co 0.1 mn 0.1 o 2 The material, conductive carbon black and polyethylene oxide-polyvinylidene fluoride are added into tetrahydrofuran at a mass ratio of 90:4:6 and fully mixed to prepare positive electrode slurry;

[0033] Step 3: Coating the positive electrode slurry evenly on the aluminum foil with a coating thickness of 25 μm, drying at a temperature of 110°C to 150°C, and then rolling and cutting to obtain the positive electrode sheet;

[0034] Step 4. Melt and mix lithium lanthanum zirconium oxide, polyv...

Embodiment 2

[0039] A novel preparation method of a solid-liquid battery with a lithium metal negative extremely high voltage positive electrode, the only difference from Example 1 is that the positive electrode slurry in step 2 is made of LiNi 0.5 mn 1.5 o 4 , conductive carbon black and polyoxyethylene-polyvinylidene fluoride are obtained by adding and mixing in tetrahydrofuran at a mass ratio of 45:2:3.

Embodiment 3

[0041] A novel method for preparing a solid-liquid battery with a lithium metal negative extremely high voltage positive electrode, the only difference from Example 1 is that the ether electrolyte consists of dimethyl carbonate, LiFSI and additives in a mass ratio of 7:5:1 Mixing, the ester electrolyte consists of 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether, LiTFSI and trifluoroethylene carbonate in a mass ratio of 6:6: 1 for mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com