Thionyl chloride production system

A production system, technology of thionyl chloride, applied in the direction of thionyl chloride, sulfur and halogen compounds, etc., can solve the problems of increased floor space and investment, cumbersome process, increased system tail gas volume, etc., to reduce process complexity and , reduce process risk, and meet the effect of cooling demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

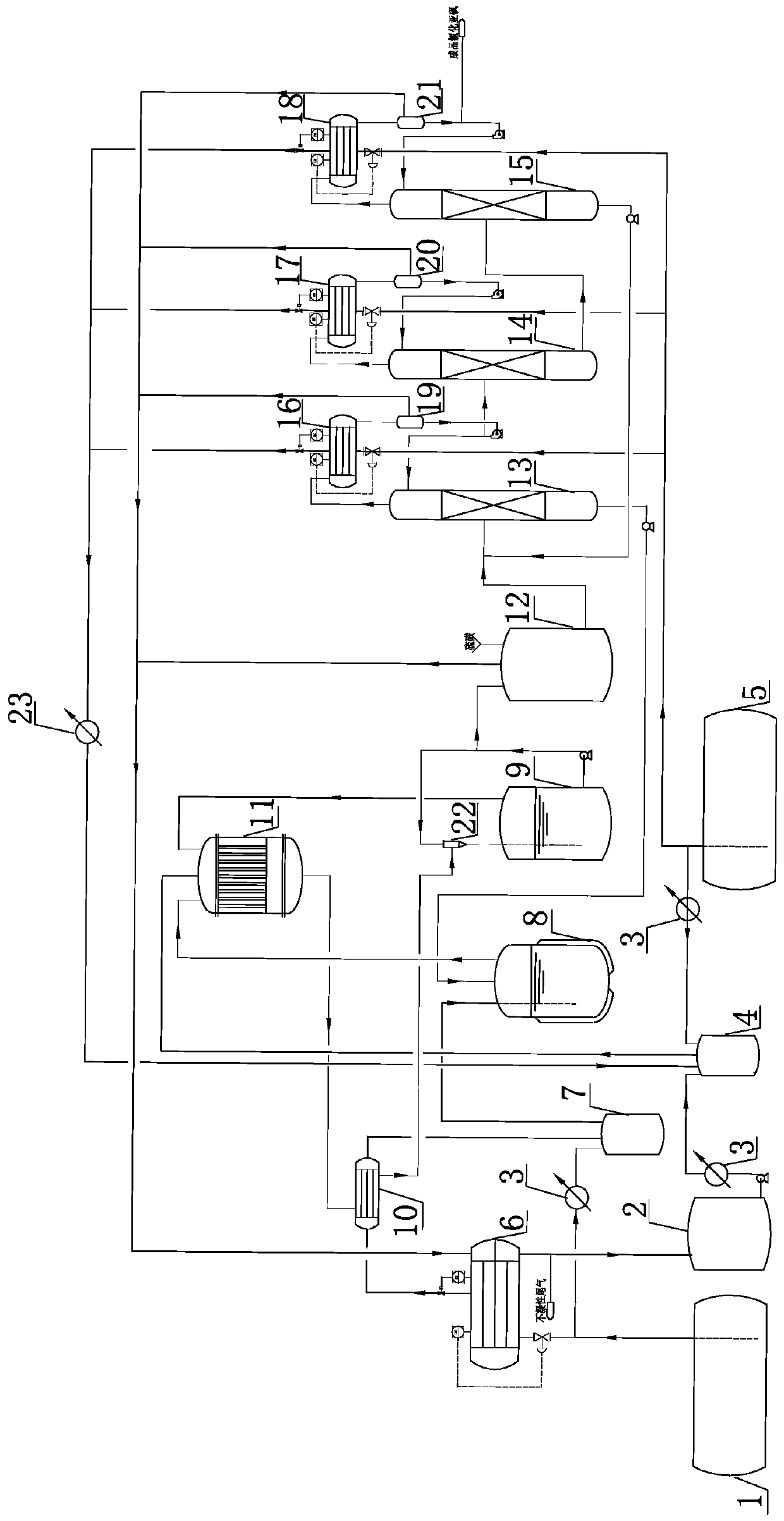

[0043] The thionyl chloride production system of the present invention comprises sulfur dioxide storage tank 5, weight removal tower 13, synthesis kettle 8, sulfur mixing kettle 12, catalytic reactor 11 and liquid chlorine storage tank 1, and liquid chlorine storage tank 1 passes through pipe The road is connected with the second buffer tank 7, and the second buffer tank 7 is connected with the synthesis kettle 8 through a pipeline; the bottom of the weight removal tower 13 is connected with the synthesis kettle 8 through a pipeline, and the synthesis kettle 8 is connected with the catalytic reactor 11 through a pipeline; Sulfur dioxide storage tank 5 links to each other with first buffer tank 4 by pipeline, and first buffer tank 4 links to each other with catalytic reactor 11 through pipeline; Catalytic reactor 11 bottom links to each other with catalytic condenser 10 through pipeline, catalytic condenser 10 bottom Link to each other with injector 22 through pipeline, injector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com