Terbium coordination compound composite fluorescent material taking inorganic salt as matrix, and preparation method thereof

A technology for compounding fluorescent and terbium complexes, which is applied in the field of fluorescent materials and can solve the problems of limited application of rare earth complexes and difficulties in the recovery of rare earth complexes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a second aspect, the present invention provides a method for preparing a composite fluorescent material containing a terbium complex, preferably preparing the above-mentioned composite fluorescent material, and the preparation method includes the following steps:

[0038] Step 1: mixing a terbium-containing compound with an organic acid;

[0039] Step 2: preparing matrix substances;

[0040] Step 3: reacting the matrix substance with the mixed solution of step 1;

[0041] Step 4: post-processing to obtain the final product.

[0042] Step 1, mixing a terbium-containing compound with an organic acid;

[0043] In step 1, the terbium-containing compound is an inorganic salt of terbium, such as terbium nitrate, terbium chloride, preferably terbium chloride;

[0044] The organic acid is that the organic acid is o-chlorobenzoic acid, phthalic acid, salicylic acid, preferably phthalic acid;

[0045] A solvent is also added during the mixing, and the solvent is one or mor...

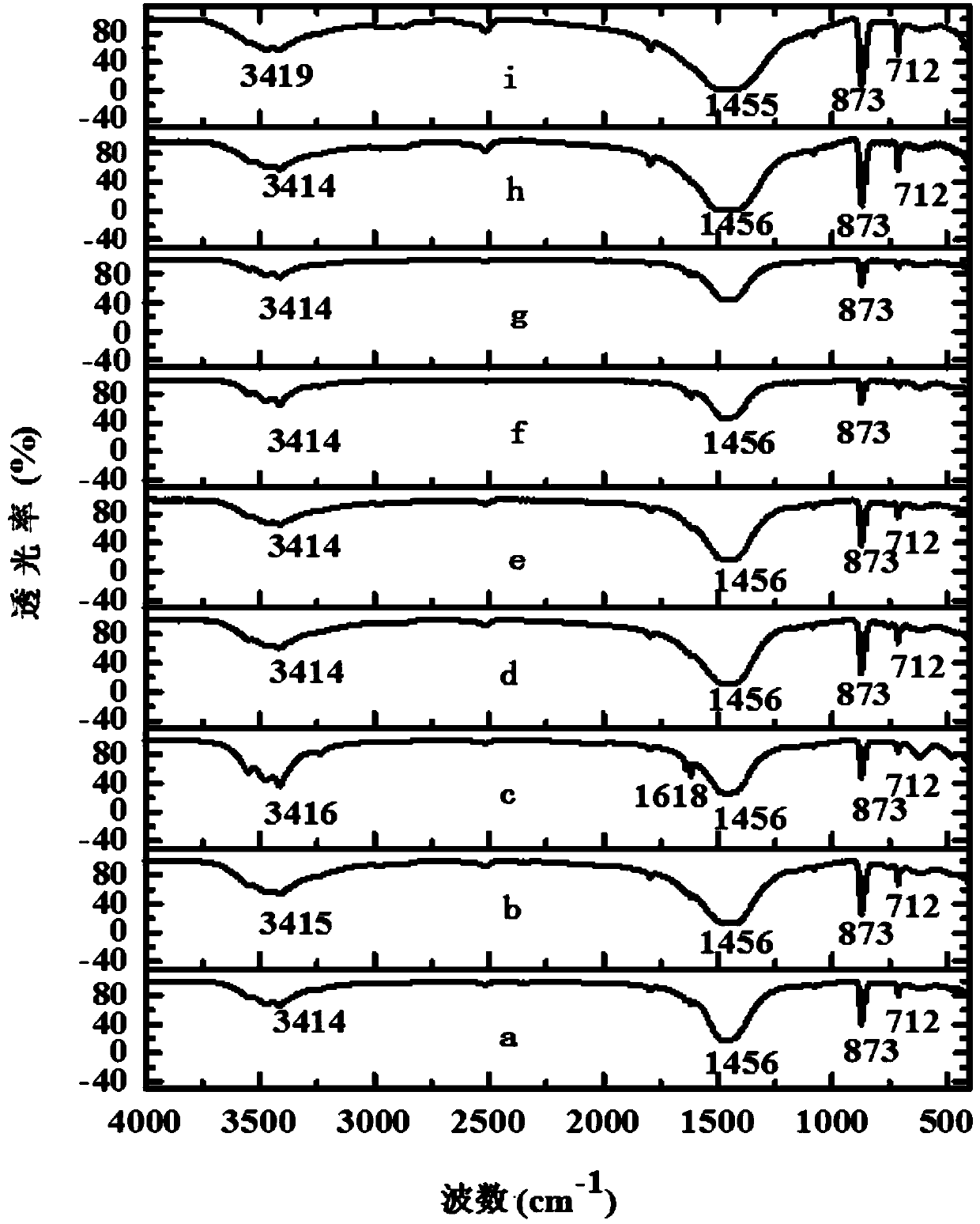

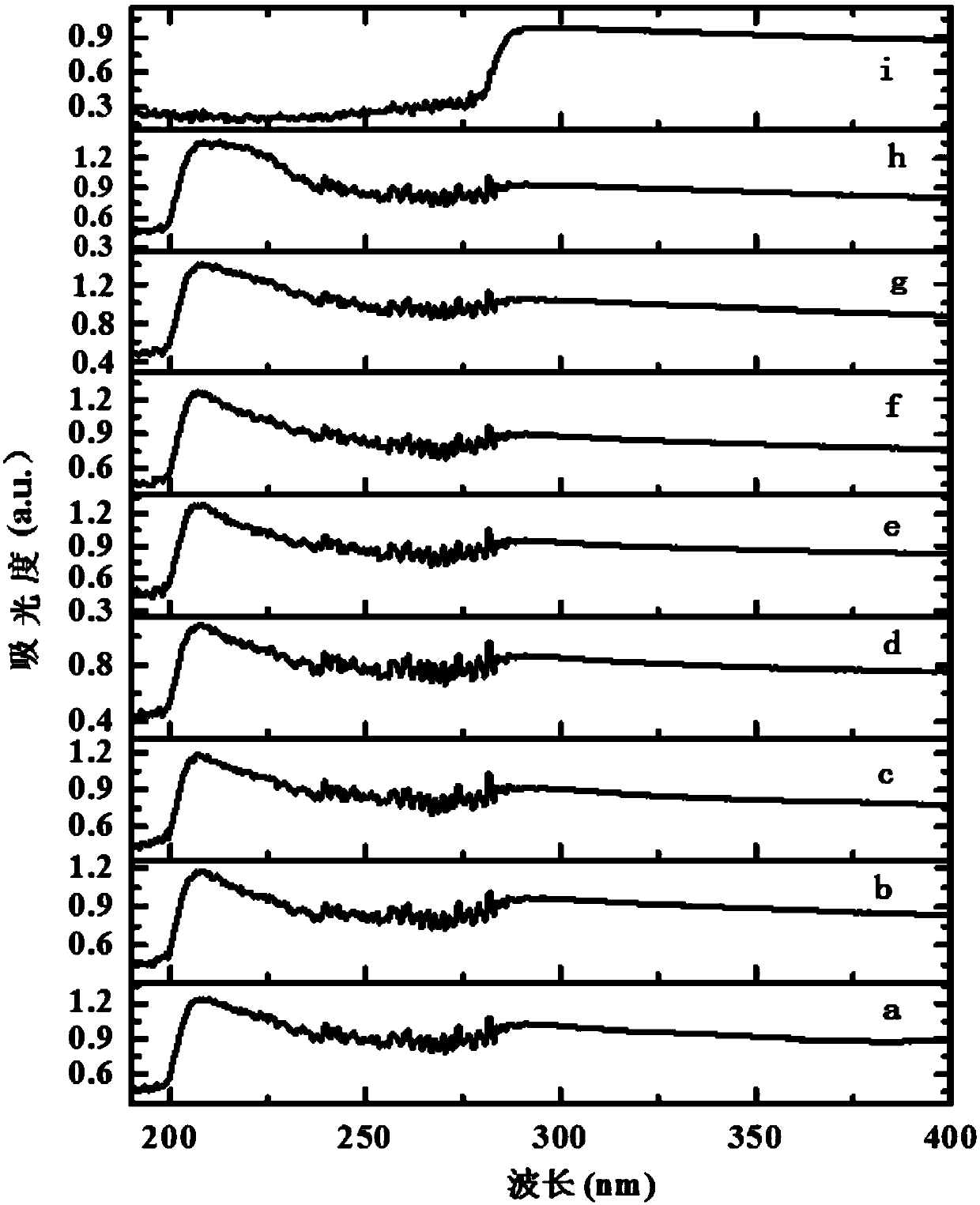

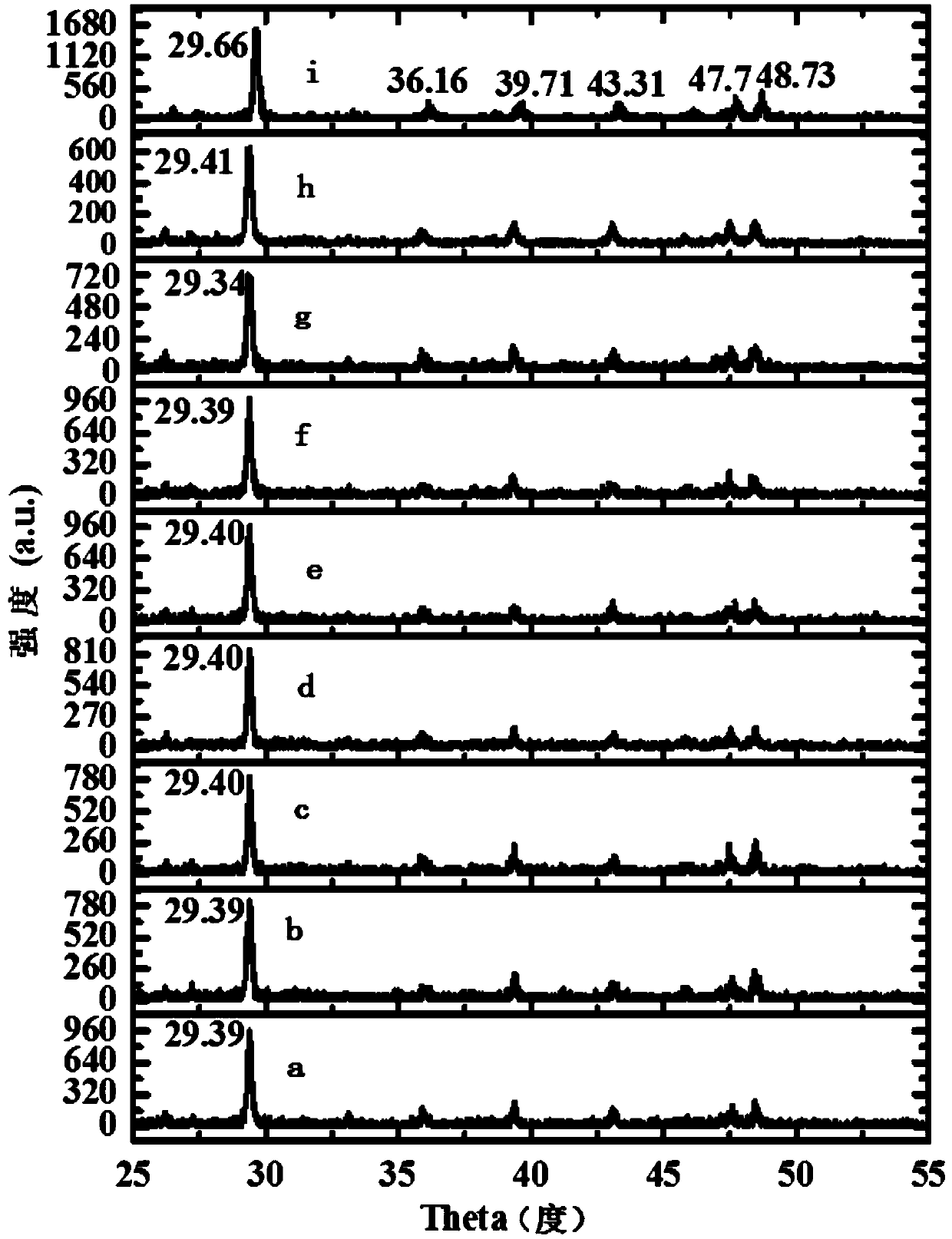

Embodiment 1

[0098] Use an analytical balance to quickly weigh 1 mmol (0.3734 g) of terbium chloride and 3 mmol (0.4984 g) of phthalic acid that have been prepared, and pour them into a 250 mL three-hole round-bottomed flask equipped with a spherical reflux condenser. Stopper the remaining two holes, measure 10mL of absolute ethanol with a graduated cylinder, pour it into a three-hole round bottom flask, stir on a magnetic stirrer, and oscillate ultrasonically for 10 minutes;

[0099] Weigh 1.0000g of anhydrous calcium carbonate CaCO with an analytical balance 3 In a 50mL beaker, add 20mL of absolute ethanol, put it into an ultrasonic cleaner, and ultrasonically oscillate for 30min under the condition of constant stirring with a glass rod;

[0100] Ultrasonic shaken CaCO 3 The solution was quickly poured into the above-mentioned three-hole round-bottomed flask, and allowed to heat, stir and reflux together with terbium chloride and phthalic acid solution for 2.0 h;

[0101] Stop heating,...

Embodiment 2~8

[0103] The difference between embodiment 2~8 and embodiment 1 is that used calcium carbonate CaCO 3The quality is different, and the quality of calcium carbonate used in embodiments 2~8 is respectively 2.0g, 3.0g, 4.0g, 5.0g, 6.0g, 7.0g, 8.0g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com