Cold/thermal light source double-response fluorescence chameleon fiber and preparation and application thereof

A color-changing fiber and responsive technology, which is applied to the dual-responsive fluorescent color-changing fiber of cold/heat light source and its preparation and application fields, can solve the problems of low fiber strength, inability to change multiple colors and light sensing indications, and difficulty in weaving. , to achieve the effect of wide color selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

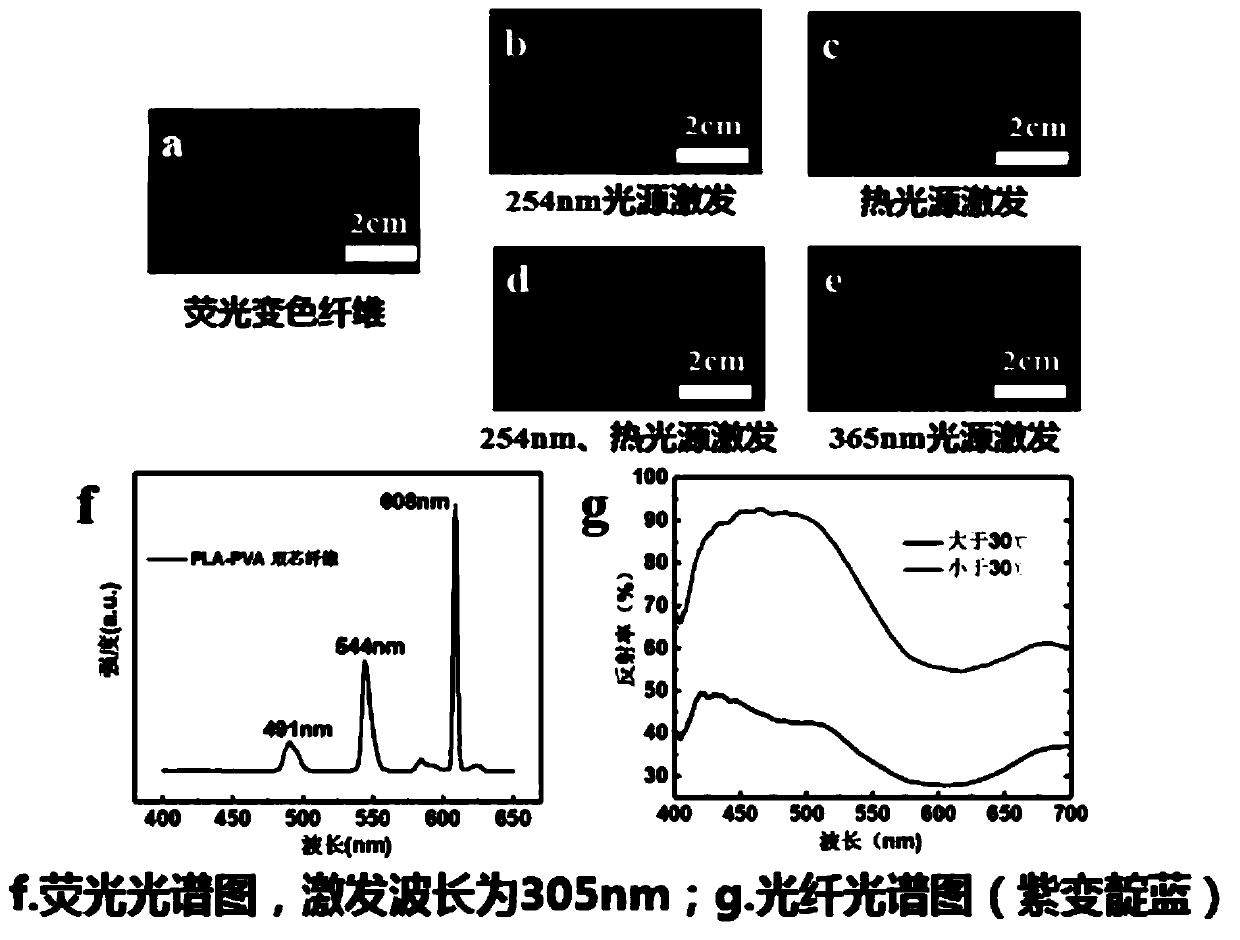

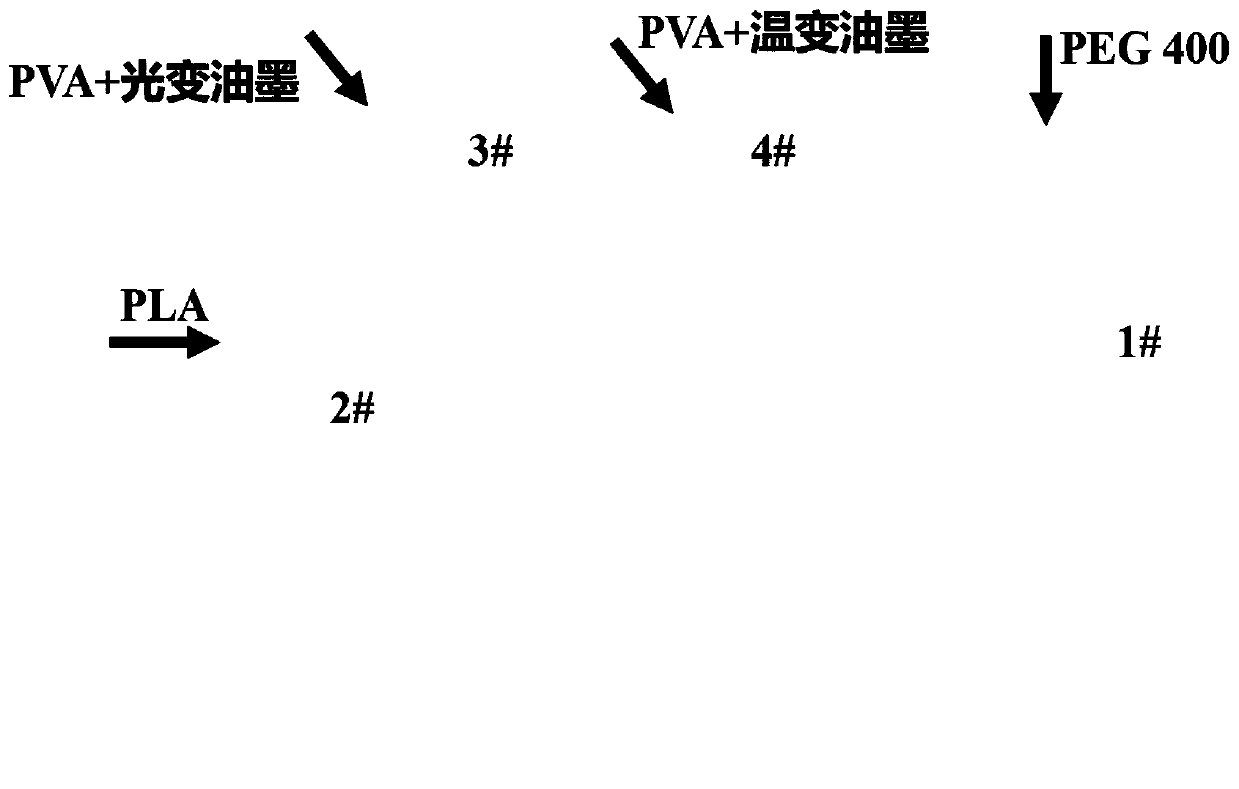

[0041] (1) Disperse 25g of polylactic acid particles in 75g of dichloromethane solvent, ultrasonically disperse for 8 hours to obtain a uniform and clear polylactic acid solution, weigh 100mL of polyethylene glycol 400 for later use; 5g of green fluorescent ink, weigh 5g of ink that changes from gray to cyan at a heat radiation temperature of 28°C, disperse cold light source fluorescent (photoluminescence) ink and hot light source color change (temperature-sensitive color change) ink in 90g to remove Add 5g of polyvinyl alcohol to deionized water mixed with cold light source fluorescence (photoluminescence) ink and heat light source color change (temperature-sensitive color change) ink, and ultrasonically disperse for 7 hours to obtain a 254nm ultraviolet light excitation. The mixed aqueous solution of white green fluorescent ink and polyvinyl alcohol, and the mixed aqueous solution of gray-colored ink and polyvinyl alcohol with a heat radiation temperature above 28°C are ready...

Embodiment 2

[0049] (1) Disperse 22g of polylactic acid particles in 78g of dichloromethane solvent, ultrasonic 8h to obtain a uniform and clear polylactic acid solution, weigh 140mL of polyethylene glycol 400 for later use; weigh it under the excitation of 254nm ultraviolet light from white to green fluorescence Weigh 7g of the ink that changes from purple to indigo at a heat radiation temperature of 31°C, and disperse the fluorescent (photoluminescence) ink caused by the cold light source and the color-changing (temperature-sensitive discoloration) ink caused by the hot light source in 85g of deionized water, respectively. , and add 8g polyvinyl alcohol to the deionized water mixed with cold light source fluorescence (photoluminescence) ink and heat light source color change (temperature-sensitive color change) ink, and ultrasonically disperse for 7 hours to obtain a white luminescence under the excitation of 254nm ultraviolet light. A mixed aqueous solution of 12g of green fluorescent in...

Embodiment 3

[0053] (1) Disperse 20g of polylactic acid particles in 80g of dichloromethane solvent, ultrasonically disperse for 8 hours to obtain a uniform and clear polylactic acid solution, weigh 200mL of polyethylene glycol 400 for later use; 9g of green fluorescent ink, weigh 9g of ink that changes from purple to indigo at a heat radiation temperature of 28°C or more, and disperse the fluorescent (photoluminescent) ink caused by cold light source and the color-changing (temperature-sensitive color-changing) ink caused by hot light source in 81g to remove Add 10g of polyvinyl alcohol to deionized water mixed with cold light source fluorescence (photoluminescence) ink and thermal light source color change (temperature-sensitive color change) ink, and ultrasonically disperse for 7 hours to obtain The mixed aqueous solution of white green fluorescent ink and polyvinyl alcohol, and the mixed aqueous solution of ink and polyvinyl alcohol that change from purple to indigo at a heat radiation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com