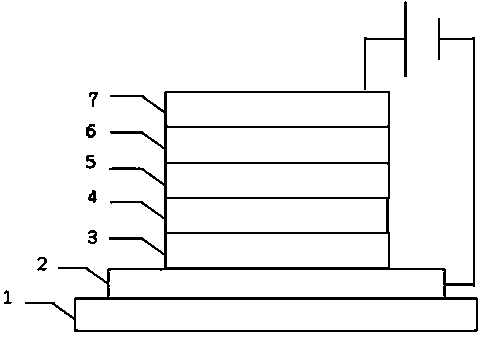

Quantum dot light-emitting diode and preparation method thereof

A quantum dot light-emitting and diode technology, which is used in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices to achieve the effects of improving luminous efficiency, promoting transmission, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: The following uses titanium acetate, ethanol, sodium hydroxide, PFN, and ethanol as examples for detailed introduction.

[0054] Add appropriate amount of titanium acetate to 50ml ethanol to form a concentration of 0.5M titanium acetate solution, at 70 o Stir to dissolve at C; dissolve sodium hydroxide in 10ml ethanol to form a sodium hydroxide solution, add sodium hydroxide solution to the titanium acetate solution (the molar ratio of sodium hydroxide to titanium ions is 4:1, pH=12), Continue stirring at 70°C for 4 h to form Ti(OH) 4 solution.

[0055] Subsequently, an appropriate amount of PFN was dissolved in ethanol to form a 1.5 mg / ml PFN solution.

[0056] Finally, on the treated substrate, Ti(OH) 4 The solution was spin-coated with a coater and heated at 250 o C annealed to form TiO 2 layer; and drop the PFN solution onto the TiO 2 layer, and at 100 o C annealed to form a film to form TiO 2 layer / PFN layer stack structure.

Embodiment 2

[0057] Embodiment 2: The following takes titanium nitrate, methanol, potassium hydroxide, PFN, and methanol as examples for detailed introduction.

[0058] An appropriate amount of titanium nitrate was added to 50ml of methanol to form a concentration of 0.5M titanium nitrate solution, at 60 o Stir and dissolve under C; dissolve potassium hydroxide in 10ml methanol to form sodium hydroxide solution, add sodium hydroxide solution to titanium nitrate solution (the molar ratio of potassium hydroxide to titanium ions is 4:1, pH=12), Continue stirring at 60°C for 4h to form Ti(OH) 4 solution.

[0059] Subsequently, an appropriate amount of PFN was dissolved in methanol to form a 1.5 mg / ml PFN solution.

[0060] Finally, on the treated substrate, Ti(OH) 4 The solution was spin-coated with a coater and heated at 250 o C annealed to form TiO 2 layer; and drop the PFN solution onto the TiO 2 layer, and at 100 o C annealed to form a film to form TiO 2 layer / PFN layer stack struc...

Embodiment 3

[0061] Embodiment 3: The following uses titanium chloride, propanol, lithium hydroxide, PFN, and propanol as examples for detailed introduction.

[0062] Add an appropriate amount of titanium chloride to 50 ml of propanol to form a titanium chloride solution with a concentration of 0.5 M, at 80 o C under stirring to dissolve. Dissolve lithium hydroxide in 10 ml propanol to form a lithium hydroxide solution, add lithium hydroxide solution to the titanium chloride solution (the molar ratio of lithium hydroxide to titanium ions is 4:1, pH=12), and continue to Stir at 80°C for 4 h to form Ti(OH) 4 solution.

[0063] Subsequently, an appropriate amount of PFN was dissolved in propanol to form a 1.5 mg / ml PFN solution.

[0064] Finally, on the treated substrate, Ti(OH) 4 The solution was spin-coated with a coater and heated at 250 oC annealed to form TiO 2 layer; and drop the PFN solution onto the TiO 2 layer, and at 100 oC Annealed to form a film to form TiO 2 layer / PFN la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com