Organic light emitting diode modified by gold nanoparticle and graphene oxide composite structure and preparation method of organic light emitting diode

A composite technology of gold nanoparticles and graphene, which is applied in nanotechnology, nanotechnology, organic semiconductor devices, etc., to achieve the effects of improving electroluminescent performance, balancing the number of holes and electron pairs, and improving brightness and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

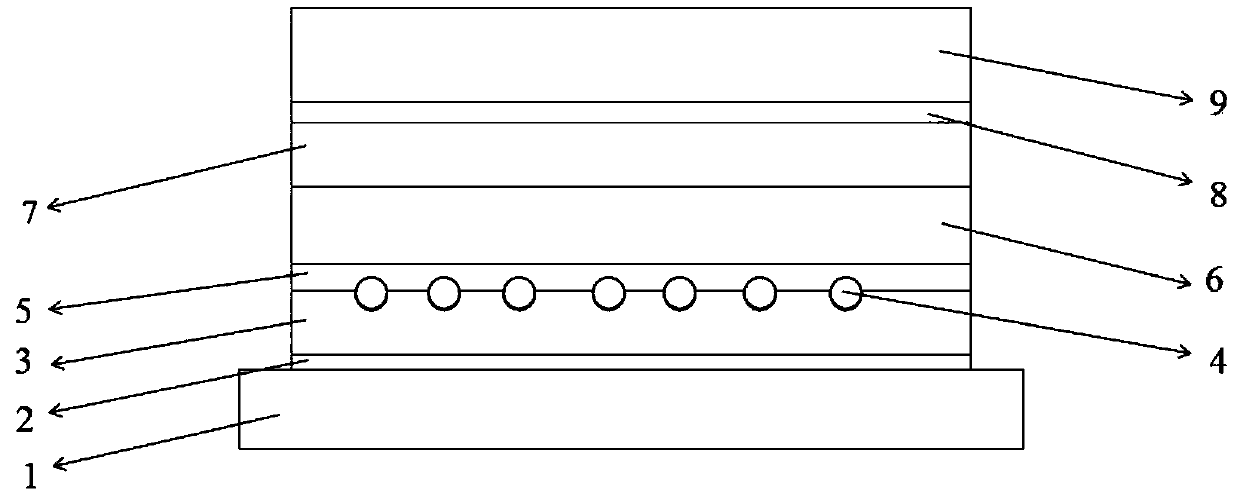

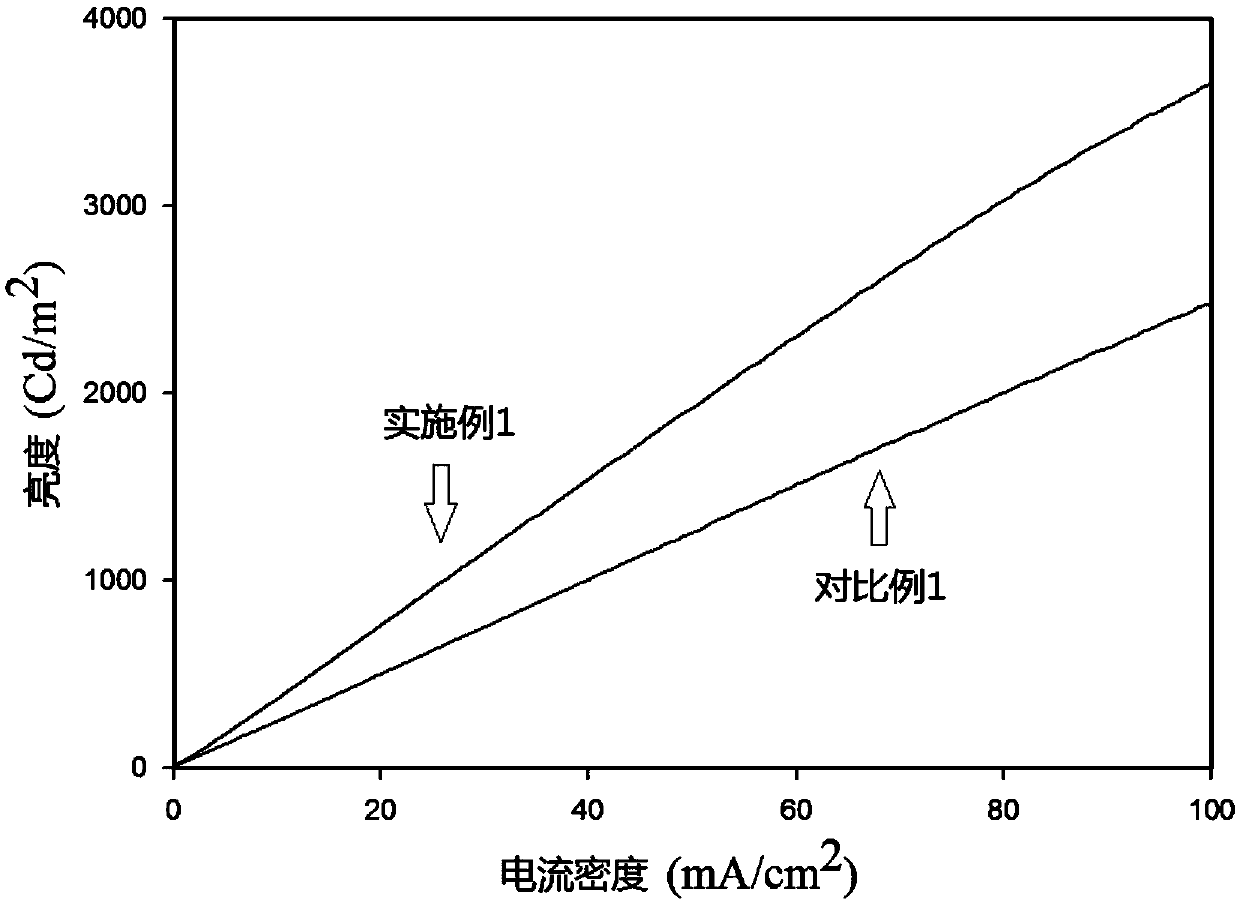

[0034] The invention provides an organic light-emitting diode (OLED) modified by gold nanoparticles based on graphene oxide as a hole injection layer and a preparation method thereof, such as figure 1 As shown, the organic light-emitting diode is in order from bottom to top: ITO glass substrate 1, graphene oxide layer 2, NPB hole transport layer 3, gold nanoparticle layer 4, NPB barrier layer 5, Alq 3 Luminescent layer 6, Alq 3 Electron transport layer 7, LiF electron injection layer 8, metal cathode 9. The preparation process is as follows:

[0035] (1) The ITO glass substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 minutes respectively, then dried with pure nitrogen gas, and finally treated with oxygen plasma for 5 minutes.

[0036] (2) Spin-coat the GO solution with a concentration of 0.25mg / ml on the cleaned glass substrate at a rotation speed of 6000-8000r / min, a time of 40-60S, and anneal at 70-130°C for 5-10min.

[0037] (...

Embodiment 2

[0043] The present invention also provides a kind of organic light-emitting diode (OLED) based on gold nanoparticle graphene oxide composite structure modification hole transport layer and preparation method thereof, and the method comprises the following steps:

[0044] (1) The ITO glass substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 minutes respectively, then dried with pure nitrogen gas, and finally treated with oxygen plasma for 5 minutes.

[0045] (2) Put the glass substrate in (1) into the thermal evaporation system, vacuumize, when the pressure is lower than 10 -7 After Torr, 30nm NPB was deposited on the substrate as a hole transport layer by thermal evaporation at a deposition rate of 0.05nm / s.

[0046] (3) With 20ml, 0.0025mol / l chloroauric acid solution is added 1.8ml under the condition of boiling water, the gold nanoparticle solution that 0.05g / ml trisodium citrate reacts for 10min and n-butylamine modified 1mg / ml ...

Embodiment 3

[0050] The present invention also provides a kind of organic light-emitting diode (OLED) and preparation method thereof based on gold nanoparticle graphene oxide composite structure as hole injection layer, and the method comprises the following steps:

[0051] (1) The ITO glass substrate was ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 5 minutes respectively, then dried with pure nitrogen gas, and finally treated with oxygen plasma for 5 minutes.

[0052] (2) With 20ml, 0.0025mol / l chloroauric acid solution is added 1.8ml under the condition of boiling water, the gold nanoparticle solution that 0.05g / ml trisodium citrate reacts for 10min and n-butylamine modified 1mg / ml of GO solution was mixed at a volume ratio of 1:1 and reacted at 80 °C for 12 h. The obtained mixed solution is diluted to 10% and spin-coated on the cleaned glass substrate at a rotation speed of 8000-10000r / min, a time of 40-60S, and annealing at 70-130°C for 5-10min.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com