A kind of sulfoaluminate cement prepared by utilizing copper, lead and zinc smelting wastewater sludge and preparation method thereof

A technology for sulfoaluminate cement and wastewater sludge, applied in cement production and other directions, can solve the problems of pollution, large amount of wastewater treatment sludge, high cost of hazardous waste, good freeze resistance and harmless treatment , good corrosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

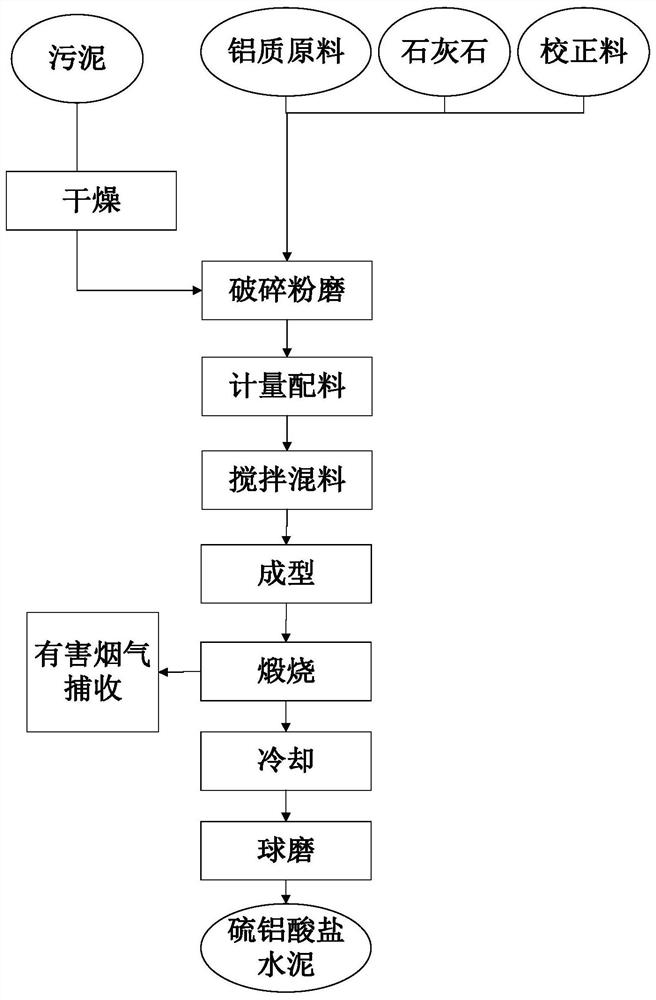

[0051] A method for preparing sulfoaluminate cement prepared by utilizing copper and lead-zinc smelting wastewater sludge, which comprises the steps of sludge drying, raw meal pulverization, calcined clinker pulverization, etc.

[0052] (a) Drying non-ferrous metal smelting waste;

[0053] Preferably, the drying temperature is 75-200°C, the drying temperature controls the calcium sulfate crystal water not to be dried, but becomes anhydrite, and the temperature is controlled so that the heavy metal components with low volatilization points in the sludge do not escape during the drying stage;

[0054] Preferably, the initial water content of the non-ferrous metal smelting waste is 10wt% to 50wt%;

[0055] (b) uniformly mixing the non-ferrous metal smelting waste after drying treatment in step (a) with pulverized limestone, bauxite and calibration raw materials to obtain a mixture and add water for granulation;

[0056] Preferably, the fineness of the crushed limestone and bauxi...

Embodiment 1

[0069] The preparation method of the sulfoaluminate cement provided by the present embodiment comprises the following steps:

[0070] (a) drying the non-ferrous metal smelting waste with an initial water content of 30wt% at 100°C;

[0071] (b) mixing the non-ferrous metal smelting waste after drying treatment in step (a) with pulverized limestone, bauxite and calibration raw materials, and it is 5 parts by weight of non-ferrous metal smelting waste and 45 parts of limestone. , 25 parts of bauxite and 25 parts of fly ash, obtain the mixture and add 6% water to carry out granulation;

[0072] Wherein, the fineness of the crushed limestone and bauxite is to pass through a 0.08mm square-hole sieve, and the sieve surplus is 8%;

[0073] (c) drying the pellets obtained in step (b) to a moisture content of less than 2%, then calcining at 1200° C. for 20 minutes, and in the process of calcining, adopting a flue gas collection system to collect copper, lead and zinc smelting wastewate...

Embodiment 2

[0078] The preparation method of the sulfoaluminate cement provided by the present embodiment comprises the following steps:

[0079] (a) drying the non-ferrous metal smelting waste with an initial water content of 10wt% at 75°C;

[0080] (b) mixing the non-ferrous metal smelting waste after drying treatment in step (a) with pulverized limestone, bauxite, and calibration raw materials, which are 8 parts of non-ferrous metal smelting waste and 42 parts of limestone by weight ratio. , 20 parts of bauxite and 32 parts of aluminum ash, obtain the mixture and add 15% water for granulation;

[0081] Wherein, the fineness of the crushed limestone and bauxite is to pass through a 0.08mm square-hole sieve, and the sieve surplus is 10%;

[0082] (c) drying the pellets obtained in step (b) to a moisture content of less than 2%, then calcining at 1400° C. for 45 minutes, and in the process of calcining, adopting a flue gas collection system to collect copper, lead and zinc smelting waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com