Polymer heavy oil emulsifying viscosity reducer and preparation method and application thereof

A high-molecular heavy oil, emulsification and viscosity-reducing technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as weak emulsification effect, poor temperature and salt resistance, and poor viscosity-reducing effect. Achieve the effect of solving poor viscosity reduction effect, high viscosity reduction rate and good emulsification viscosity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

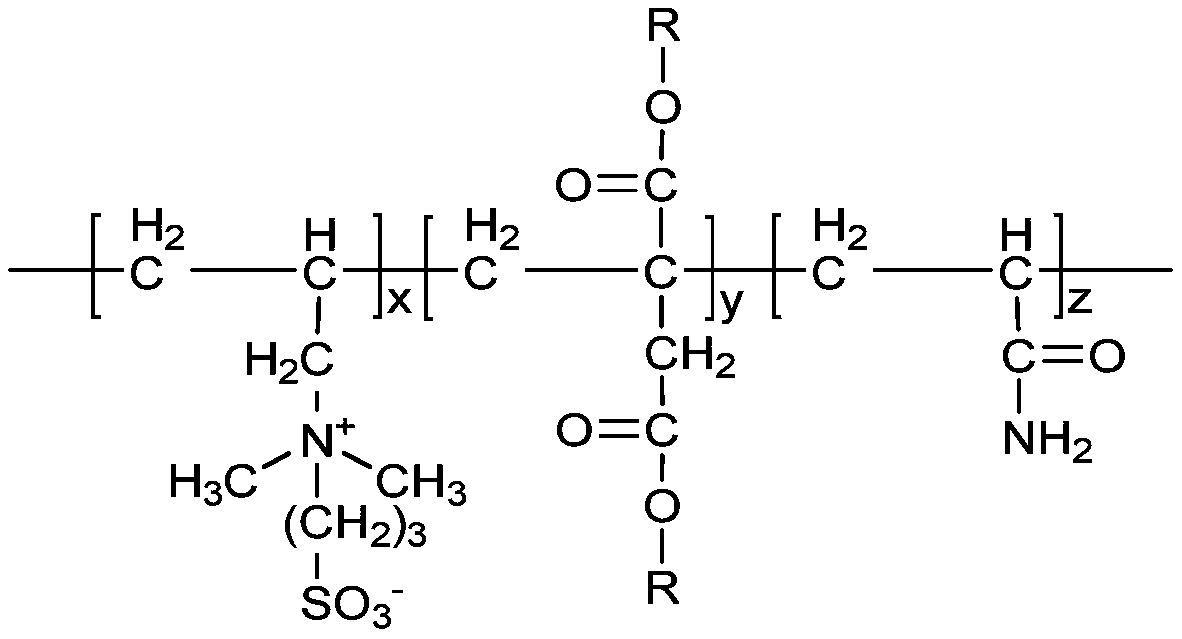

[0034] A preparation method of a polymer viscous oil emulsified viscosity reducer, comprising the following steps:

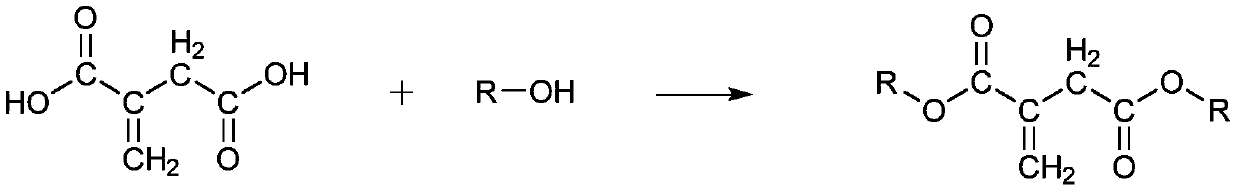

[0035] (1) Dissolve lauryl alcohol in petroleum ether, then add 1wt‰ hydroquinone, under the condition of nitrogen protection, add itaconic acid dropwise, react at 95°C for 4h, and then successively pass through at 80°C, 300r Rotary evaporation under the condition of 1 / min, recrystallization of acetone 3 times, vacuum drying at 40°C for 12 hours to obtain itaconic acid double long-chain ester monomer; the molar ratio of itaconic acid to dodecanol is 1:2.2;

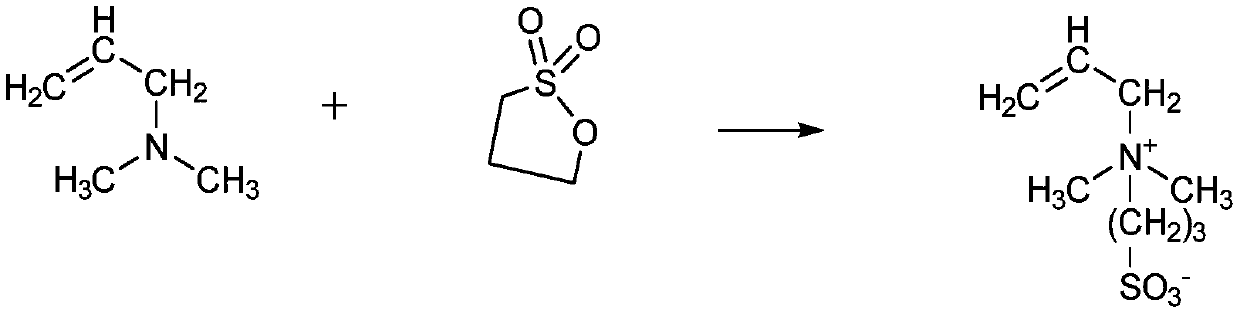

[0036] (2) Under the condition of nitrogen protection, dissolve propane sultone in tetrahydrofuran, then add dropwise in N,N-dimethylallylamine, react at 45°C for 4h, and then successively pass through at 80 ℃, 300r / min rotary evaporation, acetone recrystallization 3 times, vacuum drying at 40 ℃ for 12h to obtain sulfobetaine monomer; N,N-dimethylallylamine and propane sultone The ratio is 1:1;

[0037] (3...

Embodiment 2

[0039] A preparation method of a polymer viscous oil emulsified viscosity reducer, comprising the following steps:

[0040] (1) Dissolve myristyl alcohol in petroleum ether, then add 1wt‰ hydroquinone, add itaconic acid dropwise under the condition of nitrogen protection, react at 95°C for 5h, and then successively heat the mixture at 80°C, 300r Under the condition of rotary evaporation per minute, acetone recrystallization 4 times, and vacuum drying at 40°C for 12 hours, itaconic acid double long-chain ester monomer was obtained; the molar ratio of itaconic acid to myristyl alcohol was 1:2.4;

[0041] (2) Under the condition of nitrogen protection, dissolve propane sultone in tetrahydrofuran, then add dropwise in N,N-dimethylallylamine, react at 45°C for 4h, and then successively pass through at 80 ℃, 300r / min rotary evaporation, acetone recrystallization 3 times, vacuum drying at 40 ℃ for 12h to obtain sulfobetaine monomer; N,N-dimethylallylamine and propane sultone The rat...

Embodiment 3

[0044] A preparation method of a polymer viscous oil emulsified viscosity reducer, comprising the following steps:

[0045](1) Dissolve octadecyl alcohol in petroleum ether, then add 2wt‰ hydroquinone, under the condition of nitrogen protection, add itaconic acid dropwise, react at 100°C for 4h, and then successively pass through at 80°C, 300r Rotary evaporation under the condition of 1 / min, recrystallization of acetone 5 times, and vacuum drying at 40°C for 12 hours to obtain itaconic acid double long-chain ester monomer; the molar ratio of itaconic acid to stearyl alcohol was 1:2.5;

[0046] (2) Under the condition of nitrogen protection, dissolve propane sultone in tetrahydrofuran, then dropwise add it in N, N-dimethylallylamine, react at 55°C for 3h, and then successively pass through at 80 ℃, 300r / min rotary evaporation, acetone recrystallization 5 times, vacuum drying at 40 ℃ for 12h to obtain sulfobetaine monomer; N,N-dimethylallylamine and propane sultone The ratio is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com