Corrosion-resistant PE water supply pipe and preparation method thereof

A water supply pipe, corrosion-resistant technology, applied in the field of pipes, can solve the problems of reducing the service life of PE pipes, rotten electrochemical corrosion, limiting the scope of application, etc., to improve compatibility, improve corrosion resistance, and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

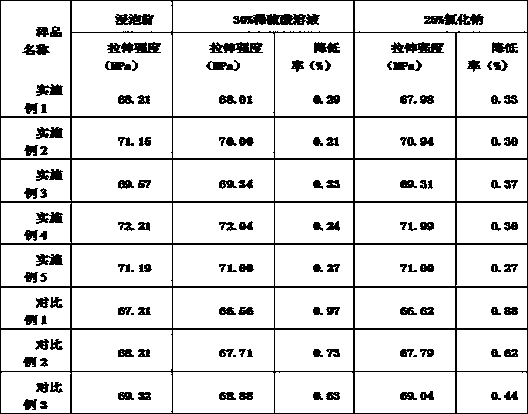

Examples

Embodiment 1

[0034] The corrosion-resistant PE water supply pipe of this embodiment is made of the raw materials with the following weight ratio:

[0035] 60 parts of PE resin powder, 20 parts of recycled polyethylene material, 10 parts of silicone rubber, 5 parts of polyacrylamide / nano-metal quantum dot composite material, 4 parts of modified nano-graphene, 3 parts of organic montmorillonite, polylactic acid fiber 2 parts, 1.5 parts of antioxidant, 1 part of silane coupling agent and 0.5 part of lubricant.

[0036] Wherein, the preparation method of the polyacrylamide / nano metal quantum dot composite material is:

[0037] (1) Put polyacrylamide in formic acid aqueous solution, carry out ultrasonic stirring, then raise the temperature to 80°C and carry out high-speed stirring until polyacrylamide is completely dissolved;

[0038] (2) Add a silane coupling agent to the above solution, heat it in a water bath at 130°C for 10 minutes under ultrasound, then distill off formic acid and water u...

Embodiment 2

[0054] The corrosion-resistant PE water supply pipe of this embodiment is made of the raw materials with the following weight ratio:

[0055] 60-80 parts of PE resin powder, 30 parts of recycled polyethylene material, 16 parts of silicone rubber, 10 parts of polyacrylamide / nano-metal quantum dot composite material, 8 parts of modified nano-graphene, 6 parts of organic montmorillonite, poly 4 parts of lactic acid fiber, 3.5 parts of antioxidant, 3 parts of silane coupling agent and 1 part of lubricant.

[0056] Wherein, the preparation method of the polyacrylamide / nano metal quantum dot composite material is:

[0057] (1) Put polyacrylamide in formic acid aqueous solution, carry out ultrasonic stirring, then raise the temperature to 90°C and carry out high-speed stirring until polyacrylamide is completely dissolved;

[0058] (2) Add a silane coupling agent to the above solution, heat it in a water bath at 130°C for 15 minutes under ultrasound, then distill under reduced pressu...

Embodiment 3

[0074] The corrosion-resistant PE water supply pipe of this embodiment is made of the raw materials with the following weight ratio:

[0075] 70 parts of PE resin powder, 25 parts of recycled polyethylene material, 13 parts of silicone rubber, 7.5 parts of polyacrylamide / nano-metal quantum dot composite material, 6 parts of modified nano-graphene, 4.5 parts of organic montmorillonite, polylactic acid fiber 3 parts, 2.5 parts of antioxidant, 2 parts of silane coupling agent and 0.7 part of lubricant.

[0076] Wherein, the preparation method of the polyacrylamide / nano metal quantum dot composite material is:

[0077] (1) Put polyacrylamide in formic acid aqueous solution, carry out ultrasonic stirring, then raise the temperature to 85°C and carry out high-speed stirring until polyacrylamide is completely dissolved;

[0078] (2) Add a silane coupling agent to the above solution, heat in a water bath at 130°C for 13 minutes under ultrasonic waves, then distill under reduced press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com