Heat-preservation and heat-insulation macromolecular environment-friendly material and preparation method thereof

An environmentally friendly material, thermal insulation technology, applied in the field of thermal insulation materials, can solve the problems of further improvement of environmental protection performance and generation of toxic smoke, etc., and achieve the effects of low preparation cost, good environmental protection, and good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

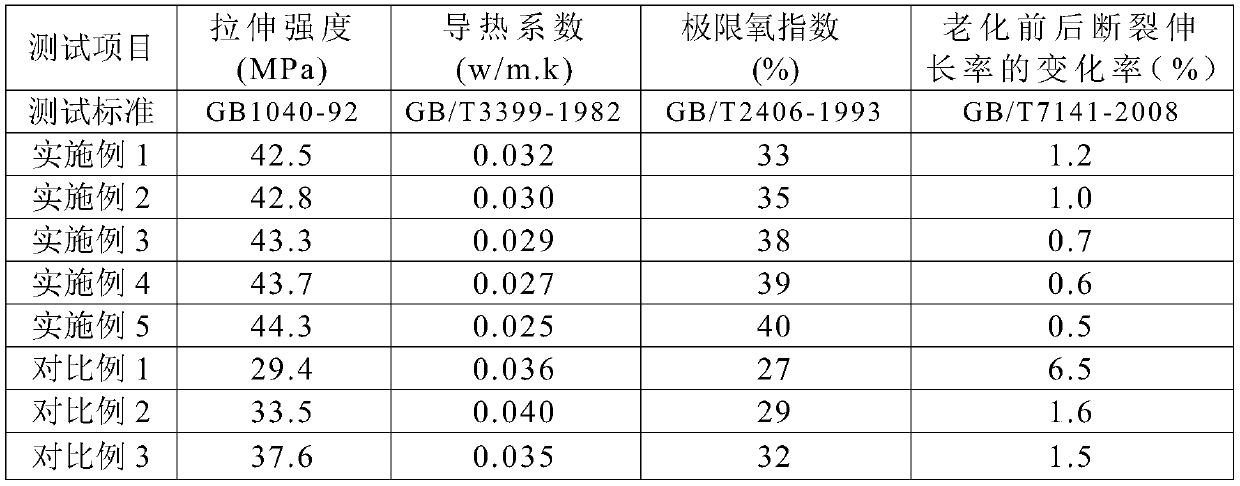

Examples

Embodiment 1

[0033] A thermal insulation polymer environmental protection material is made of the following raw materials in parts by weight: 80 parts of linear thermoplastic phenolic resin, 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(epoxy Ethylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / diniconazole / 1-(4- Chlorophenyl)vinyl borate pinacol ester / 4-triethoxysilyl vinyl benzocyclobutene copolymer 35 parts, AC blowing agent 5 parts, sodium carbonate 2 parts, antioxidant 10101 parts, cyclobutene 5 parts of oxygen soybean oil, 15 parts of solid waste-based porous material, 3 parts of cordierite powder, 2 parts of silane coupling agent KH5502.

[0034] The 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4 ,6(1H,3H,5H)-trione / diniconazole / 1-(4-chlorophenyl)vinylboronic acid pinacol ester / 4-triethoxysilylvinylbenzocyclobutene copolymer A preparation method comprising the steps of:

[0035] Ⅰ 1,3-bis(oxiran...

Embodiment 2

[0039] A thermal insulation polymer environmental protection material is made of the following raw materials in parts by weight: 85 parts of linear thermoplastic phenolic resin, 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(epoxy Ethylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / diniconazole / 1-(4- Chlorophenyl) vinyl borate pinacol ester / 4-triethoxysilyl vinyl benzocyclobutene copolymer 37 parts, ADC foaming agent 6 parts, cesium carbonate 2.5 parts, antioxidant 10761.5 parts, cyclobutene 6 parts of methyl oxyacetyllinoleate, 17 parts of solid waste-based porous material, 3.5 parts of cordierite powder, and 2.5 parts of silane coupling agent KH560.

[0040] The 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4 ,6(1H,3H,5H)-trione / diniconazole / 1-(4-chlorophenyl)vinylboronic acid pinacol ester / 4-triethoxysilylvinylbenzocyclobutene copolymer A preparation method comprising the steps of:

[00...

Embodiment 3

[0045] A thermal insulation polymer environmental protection material, which is made of the following raw materials in parts by weight: 90 parts of linear thermoplastic phenolic resin, 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(epoxy Ethylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / diniconazole / 1-(4- Chlorophenyl) vinyl borate pinacol ester / 4-triethoxysilyl vinyl benzocyclobutene copolymer 40 parts, AC blowing agent 6.5 parts, potassium carbonate 3.5 parts, antioxidant 2642 parts, cyclobutene 7.5 parts of butyl oxyfurfurate, 20 parts of solid waste-based porous material, 4 parts of cordierite powder, and 3.5 parts of silane coupling agent KH570.

[0046] The 4-chlorophenylchloromethyldimethylsilane modified 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4 ,6(1H,3H,5H)-trione / diniconazole / 1-(4-chlorophenyl)vinylboronic acid pinacol ester / 4-triethoxysilylvinylbenzocyclobutene copolymer A preparation method comprising the steps of:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com