System and method for preparing silane

A technology of silane and refined silane, which is applied in the system field of preparing electronic grade silane, can solve the problems of large consumption, high production cost, high energy consumption of sludge dehydration, etc., and achieve the effect of high yield and few reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

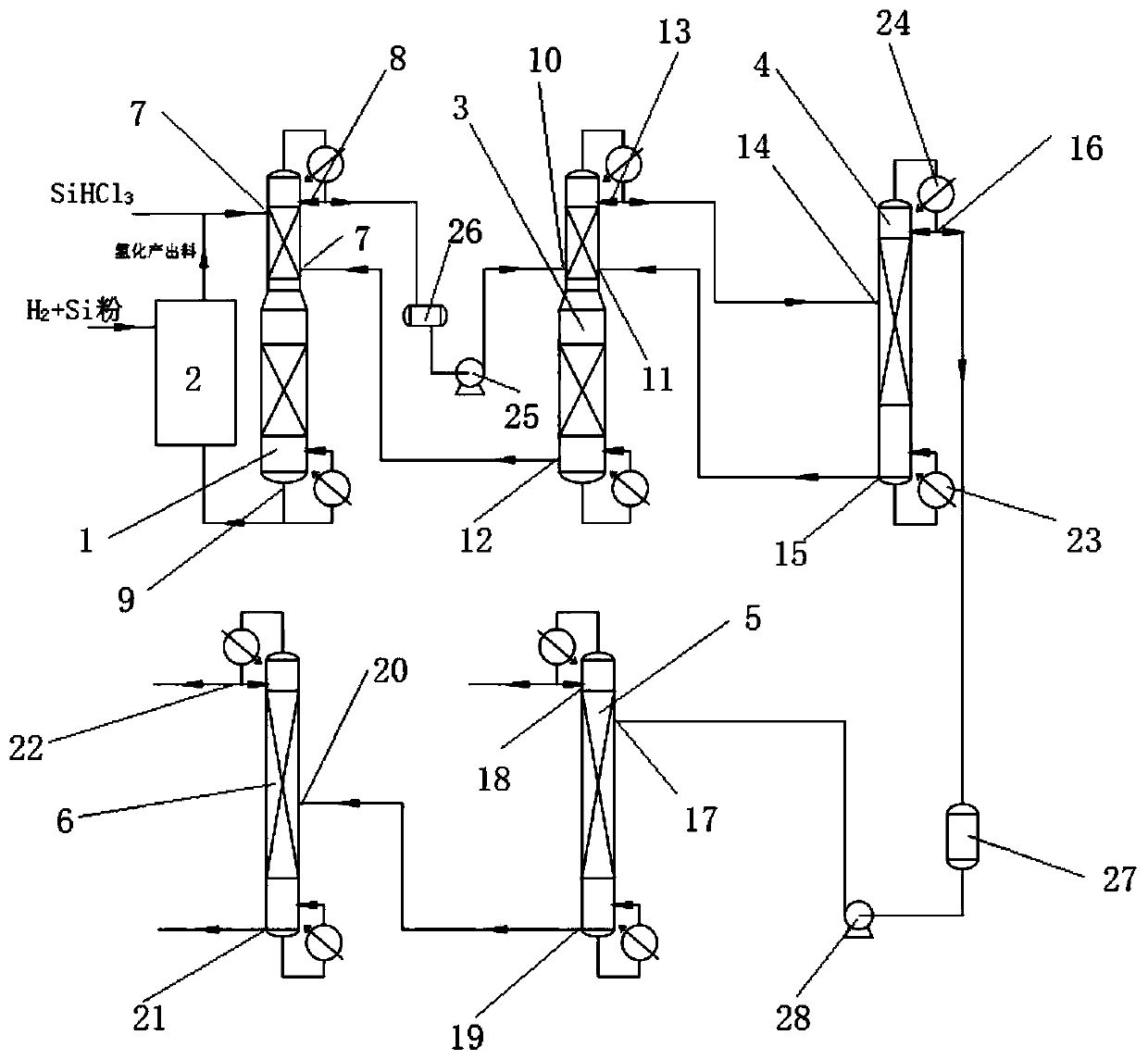

[0048] Embodiment 1 of the present invention discloses a system for preparing silane, comprising a first disproportionation reaction rectification tower 1, a tetrachlorosilane hydrogenation system 2, a second disproportionation reaction rectification tower 3, a silane crude distillation tower 4, a first silane refiner Distillation tower 5 and the second silane rectification tower 6; The first disproportionation reaction rectification tower 1 is connected with tetrachlorosilane hydrogenation system 2, and the first disproportionation reaction rectification tower 1 is connected with the second disproportionation reaction rectification tower 3 simultaneously; The disproportionation reaction rectification tower 3 is connected with the silane rectification tower 4; the downstream of the silane rectification tower 4 is sequentially connected with the first silane rectification tower 5 and the second silane rectification tower 6.

[0049] A system for preparing silane disclosed by the...

Embodiment 2~6

[0065] A kind of method for preparing silane, adopts a kind of system for preparing silane disclosed in embodiment 1, specifically comprises the following steps:

[0066] (1) Pass the hydrogenation output material or trichlorosilane into the first disproportionation reaction rectification tower, control the pressure of the first disproportionation reaction rectification tower to be 0.1-2MPa, the temperature is 20-150°C, and the feed amount of trichlorosilane Continuous reaction distillation of 200-50000Kg / h, disproportionation reaction occurs under the action of tertiary amine catalyst, and rectification separation is carried out at the same time to obtain dichlorosilane and tetrachlorosilane respectively;

[0067] (2) Tetrachlorosilane enters the tetrachlorosilane hydrogenation system to react with silicon powder and hydrogen to generate trichlorosilane and pass it into the first disproportionation reaction rectification tower for recycling;

[0068] (3) The dichlorosilane ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com