Pretreatment method of epothilone B fermentation liquor

A technology of epothilone and fermented liquid, applied in the direction of organic chemistry, etc., can solve the problems affecting the quality of epothilone B final product, cumbersome plate and frame filtration or centrifugation operation, easy to block resin column sieve plate, etc., and achieve improvement Extraction efficiency and yield, saving column time, saving organic solvent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

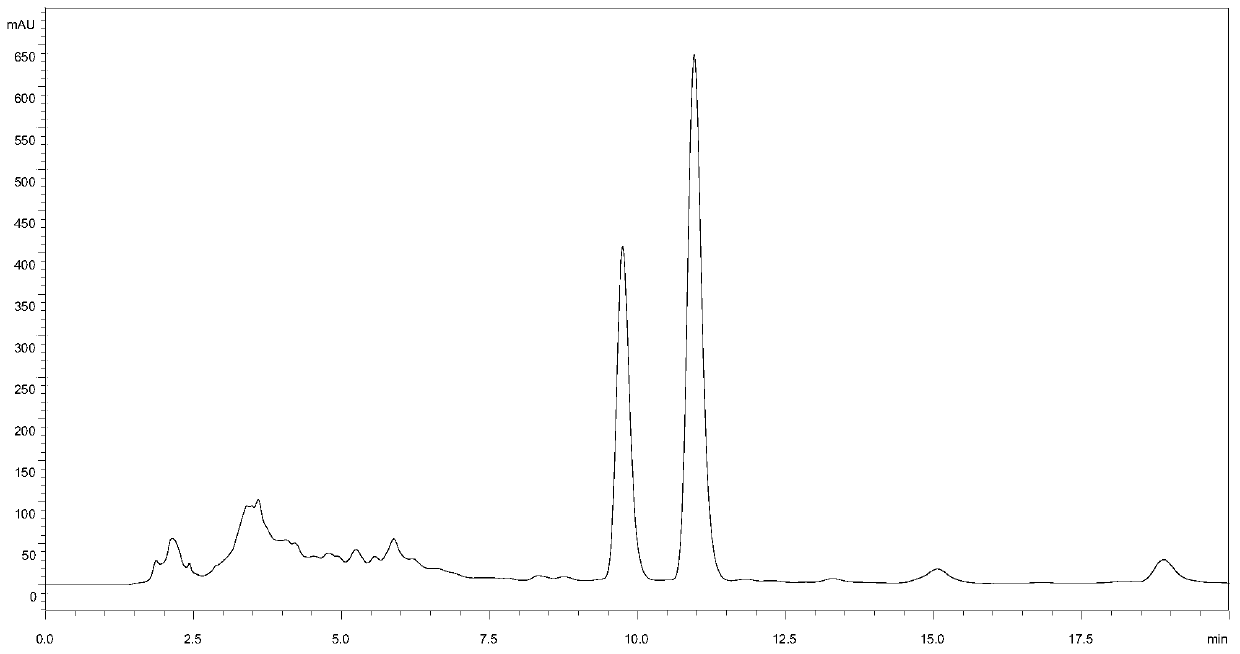

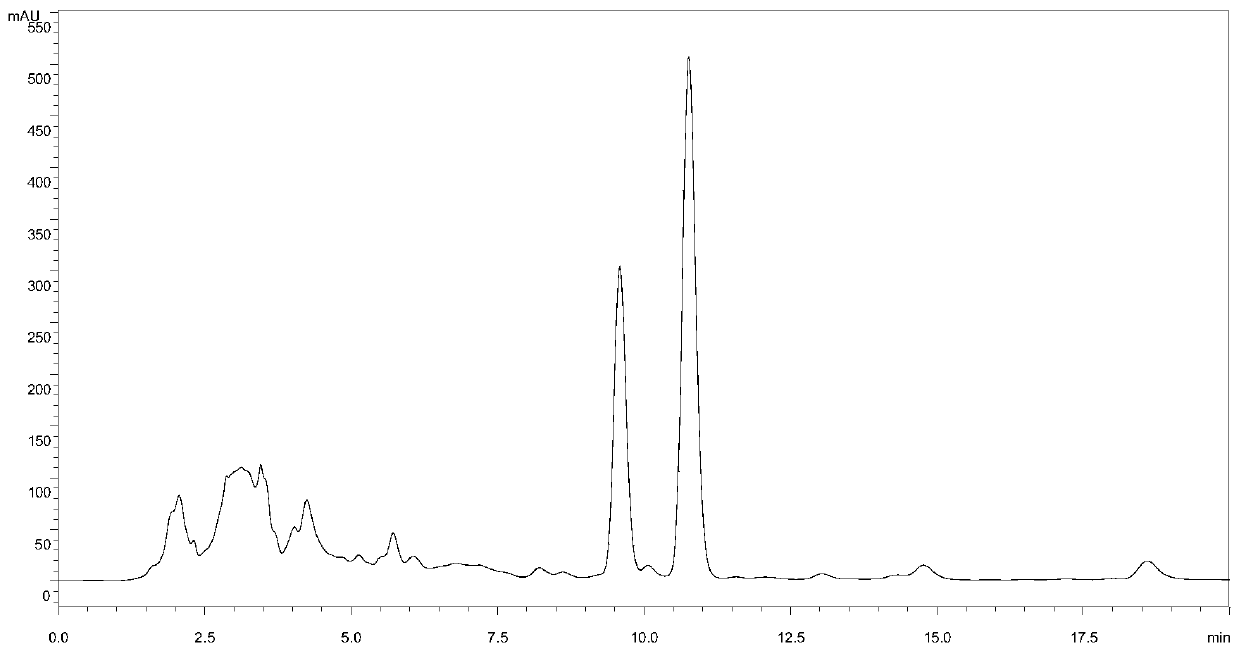

Image

Examples

Embodiment 1

[0043] 1.2m 3 Fermentation broth (epothilone B content 86.5mg / L) was left to stand for 30 minutes, and after the XAD-16N resin and bacteria settled, the fermentation broth was released from the upper layer for 1m 3 , the remaining 200L, add 40g of sodium chloride solid, stir slowly for 10min, after the sodium chloride solid is completely dissolved, take a sample to detect the remaining fermentation broth density 1.150g / cm 3 , stand still for 10-20 minutes, the bacteria are deposited in the lower layer, and the XAD-16N resin floats in the upper layer, and the fermentation broth with the bacteria is released from the lower layer, and 12Kg of the resin is collected and loaded into a stainless steel chromatography column.

[0044] Wash the stainless steel column with 50L purified water, then wash the stainless steel column with 75L volume fraction of 15% ethanol aqueous solution, and finally wash with absolute ethanol until the effluent does not contain epothilone B, and the washi...

Embodiment 2

[0046] 1.2m 3 Fermentation broth (epothilone B content 85.7mg / L) was left to stand for 30 minutes, and after the XAD-16N resin and bacteria settled, the fermentation broth was released from the upper layer for 1m 3 , the remaining 200L, add 50g of zinc sulfate heptahydrate solid, stir slowly for 10min, after the zinc sulfate heptahydrate solid is completely dissolved, take a sample to detect the remaining fermentation broth density 1.159g / cm 3 , stand still for 10-20 minutes, the bacteria are deposited in the lower layer, and the XAD-16N resin floats in the upper layer, and the fermentation broth with the bacteria is released from the lower layer, and 12Kg of the resin is collected and loaded into a polypropylene chromatography column.

[0047] Rinse the polypropylene chromatography column with 50L of purified water, then rinse the polypropylene chromatography column with 100L volume fraction of 10% ethanol aqueous solution, and finally rinse with 90% volume fraction of ethano...

Embodiment 3

[0049] 1.2m 3 Fermentation broth (epothilone B content 44.6mg / L) was left to stand for 30min, after the X-5 resin and bacteria settled, the fermentation broth was released from the upper layer for 1m 3 , the remaining 200L, add 60g of magnesium sulfate heptahydrate solid, stir slowly for 10min, after the magnesium sulfate heptahydrate solid is completely dissolved, take a sample to detect the remaining fermentation broth density 1.145g / cm 3 , stand still for 10-20 minutes, the bacteria are deposited in the lower layer, and the X-5 resin floats in the upper layer, and the fermentation broth with the bacteria is released from the lower layer, and 12Kg of the resin is collected and loaded into a polypropylene chromatography column.

[0050] Rinse the polypropylene chromatography column with 50L of purified water, then rinse the polypropylene chromatography column with 70L volume fraction of 20% methanol aqueous solution, and finally rinse with anhydrous methanol until the effluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com