Carbon nanofiber and metal composite electrode and application thereof

A nano-carbon fiber and metal composite technology, applied in battery electrodes, circuits, fuel cells, etc., can solve the problems of high electrode cost and unsuitable for large-scale application, achieve low price, improve electrocatalytic activity and electrochemical reversibility, Effects that are easy to mass produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

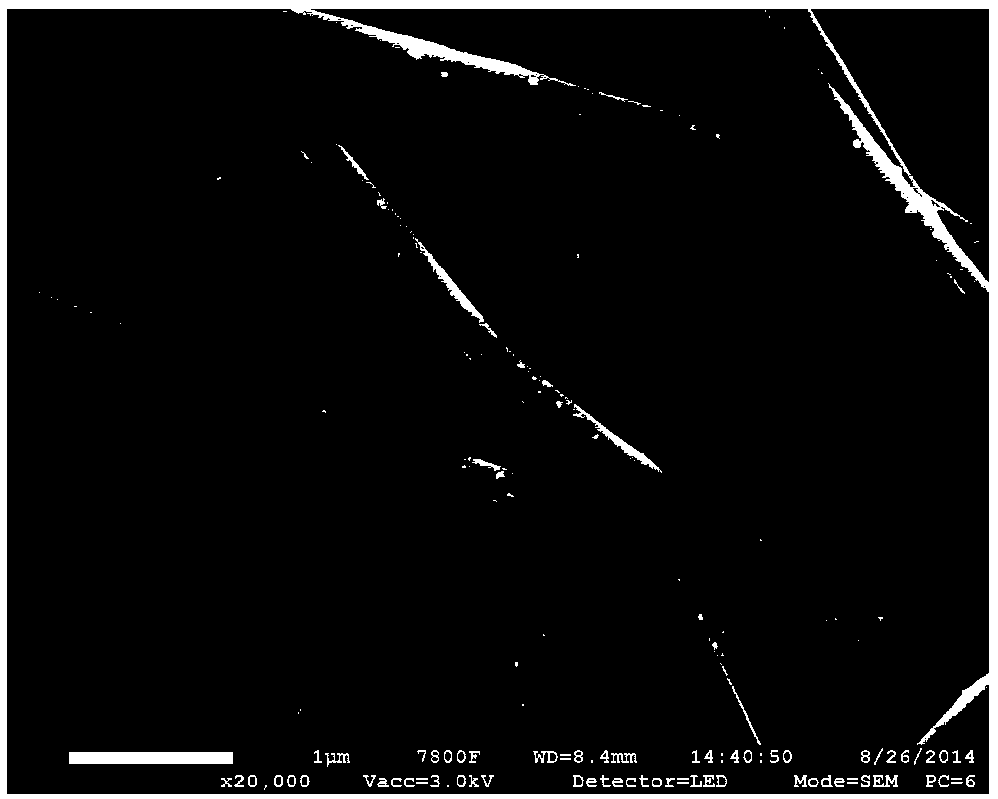

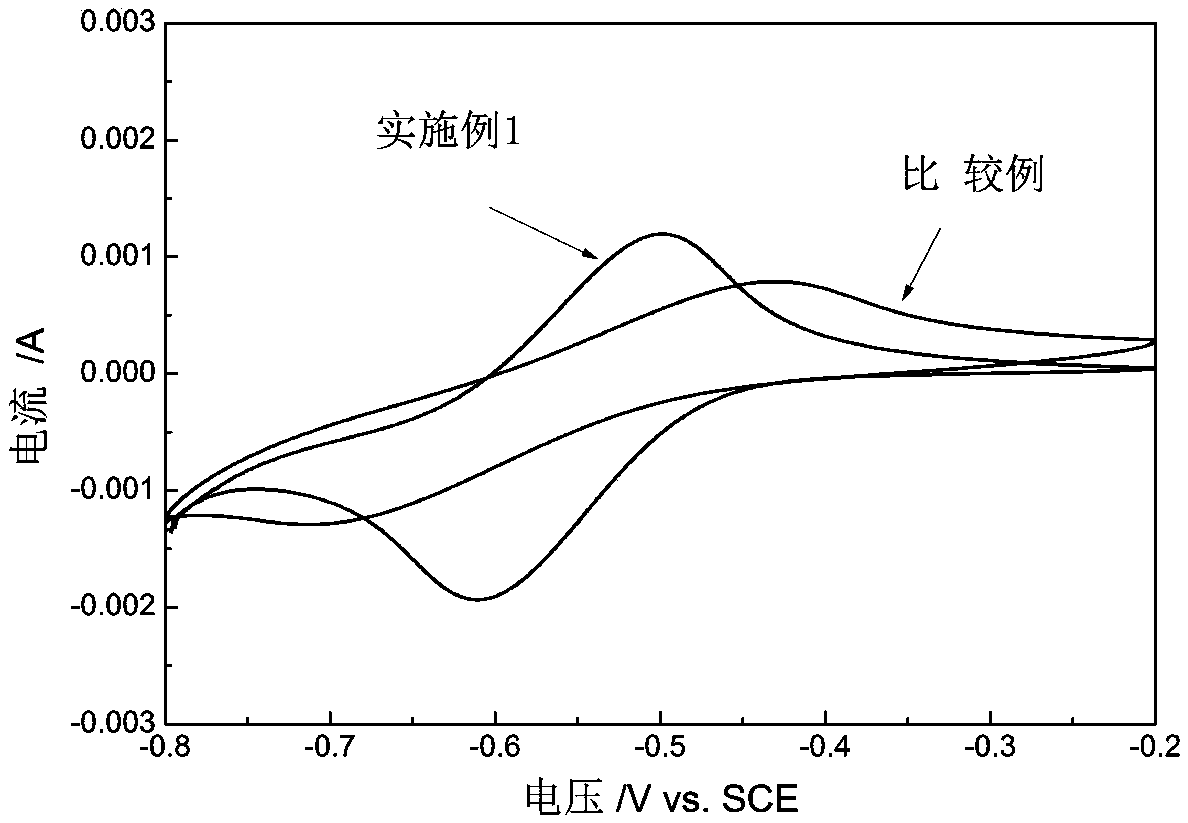

[0032] Weigh 0.5g Bi(NO 3 ) 3 ·5H 2 Dissolve O in 20g of N,N-dimethylformamide, ultrasonically disperse for 1 hour to completely dissolve, then add 2g of polyacrylonitrile powder, and stir at 70°C for 24 hours to fully dissolve. Then, 5 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 10KV voltage, 25° C., and 10% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 300°C for 2h, and then sintered at 1200°C for 2h in an argon atmosphere to reduce the metal salt in it to metal, and then cooled to room temperature, and then Oxidize in air at 450° C. for 2 h to remove the graphite sheets wrapped on the surface of Bi nanoparticles to prepare carbon nanofiber / Bi composite electrode materials. Such as figure 1 As shown, the SEM image of carbon nanofiber / Bi composite electrode material shows th...

Embodiment 2

[0035] Weigh 0.4g Pb(NO 3 ) 2 Dissolve in 20g of N,N-dimethylformamide, ultrasonically disperse for 1h to dissolve completely, then add 3g of polymethyl methacrylate powder, stir at 50°C for 24h to fully dissolve. Then, 10 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 15KV voltage, 25° C., and a relative humidity of 20%, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 280 °C for 2 h, and then sintered at 1400 °C for 2 h under an argon atmosphere to reduce the metal salt in it to metal Pb, then cooled to room temperature, and then It is oxidized in the air at 400° C. for 2 hours, and the graphite sheets wrapped on the surface of Pb nanoparticles are oxidized to remove the carbon nanofiber / Pb composite electrode material. The diameter of the carbon nanofibers in the obtained carbon nanofiber film is ab...

Embodiment 3

[0037] Weigh 0.1g of bismuth subsalicylate and disperse it in 20g of N,N-dimethylformamide, ultrasonically disperse for 1h to disperse evenly, then add 2g of polyacrylonitrile powder, stir at 60°C for 24h to fully dissolve and Mix well with bismuth subsalicylate. Then 10 mL of the above solution was placed in a syringe, and spinning was carried out under the conditions of 10KV voltage, 25° C., and 10% relative humidity, and the distance between the needle tip of the syringe and the receiving plate was 5 cm. The obtained polymer fiber / metal salt composite film was pre-oxidized in air at 280°C for 2h, and then sintered at 1400°C for 2h under an argon atmosphere to reduce the metal salt in it to metal Bi, and then cooled to room temperature, and then It is oxidized in the air at 500° C. for 1 h, and the graphite sheets wrapped on the surface of Bi nanoparticles are oxidized to remove the carbon nanofiber / Bi composite electrode material. The diameter of carbon nanofibers in the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com