Microneedle patch for losing weight and preparation method thereof

A micro-needle sticker and micro-needle technology, applied in the field of micro-needles, can solve the problems of affecting the mechanical properties of soluble micro-needles, unable to exert ideal efficacy, and low drug loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

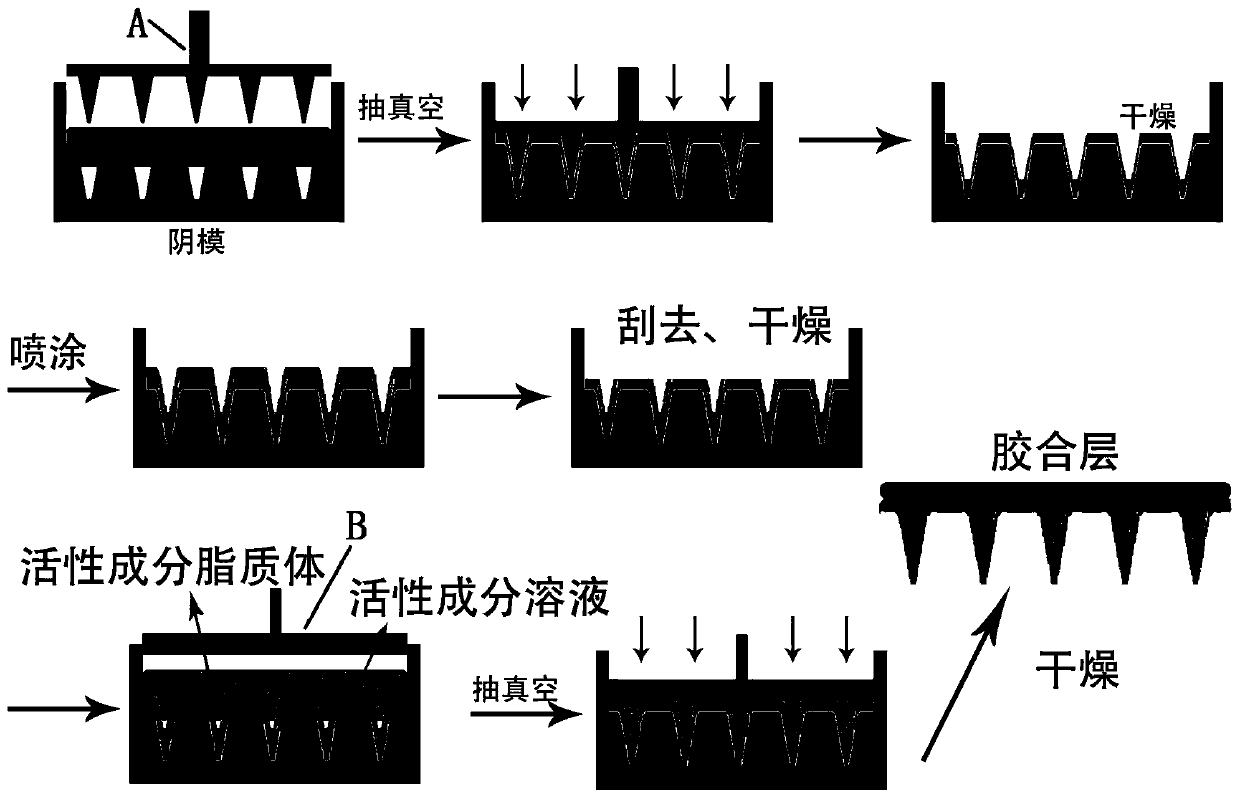

[0079] This embodiment provides a high-loaded microneedle patch for weight loss, including a microneedle body and a microneedle base, and its preparation method includes the following steps (the preparation flow chart is as follows: figure 1 shown):

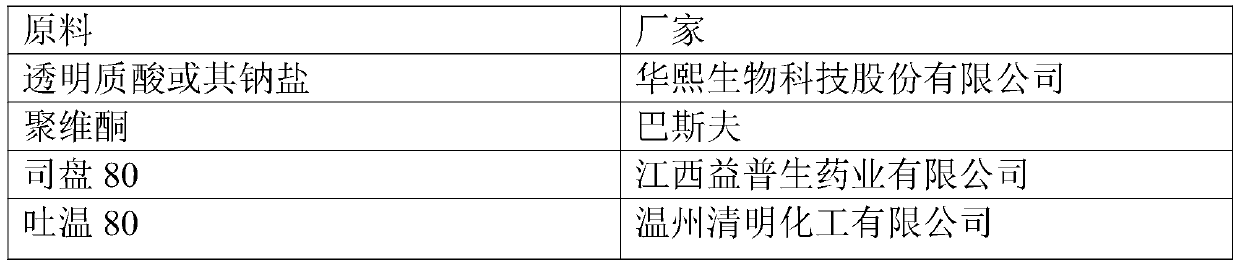

[0080] (1) Prepare the outer layer of the microneedle body: mix the raw materials according to the following parts by weight: 50 parts of sterile water, 12 parts of sodium hyaluronate (molecular weight: 28w), 309 parts of povidone K, 901 parts of povidone K, Stir well and centrifuge to remove air bubbles. Pour the resulting mixture into the microneedle female mold, vacuumize, press with metal platen A at room temperature, -0.06mpa vacuum degree, and 55% humidity, and dry at 45°C and 30% humidity for 12 hours to obtain The outer layer of the microneedle body.

[0081] (2) Spray emulsifier coating: Mix 0.1 part of Span 80 (Span 80) and 0.3 part of Tween 80 (Tween80) in a weight ratio of 1:3 to obtain an emulsion. The inner surfa...

Embodiment 2

[0088] This embodiment provides a high-loaded microneedle patch for weight loss, including a microneedle body and a microneedle base, and its preparation method includes the following steps (the preparation flow chart is as follows: figure 1 shown):

[0089] (1) Prepare the outer layer of the microneedle body: mix the raw materials according to the following parts by weight: 50 parts of sterile water, 12 parts of sodium hyaluronate (molecular weight: 28w), 309 parts of povidone K, 901 parts of povidone K, Stir well and centrifuge to remove air bubbles. Pour the resulting mixture into the microneedle female mold, vacuumize, press with metal platen A at room temperature, -0.06mpa vacuum degree, and 55% humidity, and dry at 45°C and 30% humidity for 12 hours to obtain The outer layer of the microneedle body.

[0090] (2) Spray emulsifier coating: Mix 0.1 part of Span 80 (Span 80) and 0.3 part of Tween 80 (Tween80) in a weight ratio of 1:3 to obtain an emulsion. The inner surfa...

Embodiment 3

[0096] This embodiment provides a high-loaded microneedle patch for weight loss, including a microneedle body and a microneedle base, and its preparation method includes the following steps (the preparation flow chart is as follows: figure 1 shown):

[0097] (1) Prepare the outer layer of the microneedle body: mix the raw materials according to the following parts by weight: 50 parts of sterile water, 12 parts of sodium hyaluronate (molecular weight: 28w), 309 parts of povidone K, 901 parts of povidone K, Stir well and centrifuge to remove air bubbles. Pour the resulting mixture into the microneedle female mold, vacuumize, press with metal platen A at room temperature, -0.06mpa vacuum degree, and 55% humidity, and dry at 45°C and 30% humidity for 12 hours to obtain The outer layer of the microneedle body.

[0098] (2) Spray emulsifier coating: Mix 0.1 part of Span 80 (Span 80) and 0.3 part of Tween 80 (Tween80) in a weight ratio of 1:3 to obtain an emulsion. The inner surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com