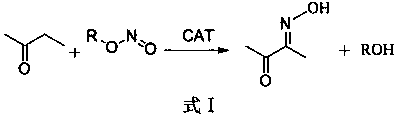

Production method of diacetyl monoxime

A production method, diacetyl technology, applied in chemical instruments and methods, oxime preparation, chemical/physical/physicochemical processes, etc., can solve the problems of high toxicity of exhaust gas, excessive ethyl nitrite, complicated operation steps, etc. Achieve the effect of meeting the needs of large-scale continuous production, shortening the reaction time, and increasing the product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 7.2kg methyl ethyl ketone and 1kg catalyst were pre-mixed and preheated to 40°C, 7.65kg ethyl nitrite was preheated to 40°C respectively and pumped into the microtube reactor at the same time through the metering pump and the gas metering pump. The reaction was carried out under the pressure of 0.4MPa, and the reaction time was 45 seconds. After the reaction was completed, samples were taken for detection, and the butanone content was 1.36%, and the diacetyl monoxime content was 83.44%.

Embodiment 2

[0027] Pre-mix 7.2kg of methyl ethyl ketone and 1kg of catalyst, preheat to 40°C, and preheat 10.8kg of tert-butyl nitrite to 40°C, and pump them into the microtube reactor at the same time through metering pump and gas metering pump respectively. The reaction was carried out under a pressure of 0.4 MPa, and the reaction time was 45 seconds. After the reaction was completed, samples were taken for detection, and the butanone content was 1.64%, and the diacetyl monoxime content was 82.47%.

Embodiment 3

[0029] 7.2kg methyl ethyl ketone and 1kg catalyst were pre-mixed and preheated to 40°C, 7.65kg ethyl nitrite was preheated to 40°C respectively and pumped into the microtube reactor at the same time through the metering pump and the gas metering pump. The reaction was carried out under the pressure of 0.5 MPa, and the reaction time was 60 seconds. After the reaction was completed, samples were taken for detection, and the butanone content was 0.85%, and the diacetyl monoxime content was 85.32%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com