A kind of neutral silicone oil silicone grease cleaning agent and its preparation method and application

A cleaning agent, silicone oil technology, applied in the directions of surface active detergent composition, detergent composition, detergent compounding agent, etc. Excellent cleaning or protection, low cost, improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

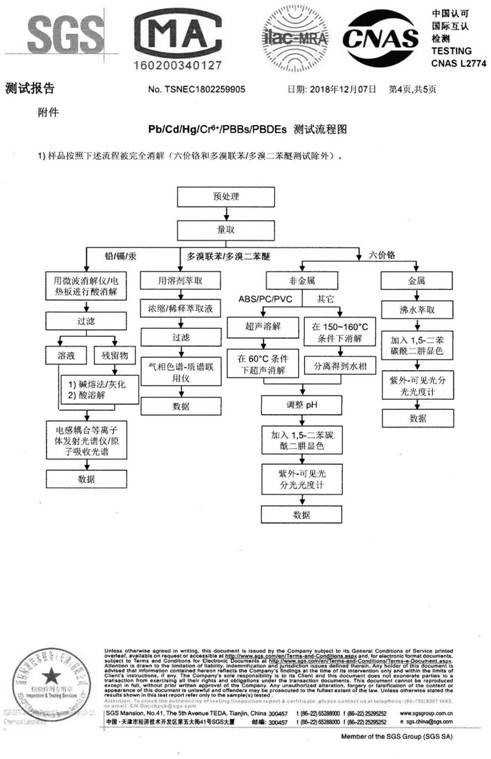

Image

Examples

preparation example Construction

[0052] The preparation method of neutral silicone oil and silicone grease cleaning agent as above, the steps are as follows:

[0053] (1) Add water into the production kettle, raise the temperature to 20-40°C, add builders and complexing agents, keep the temperature at 20-40°C, and stir for 20-30 minutes to ensure that the builders and complexing agents are completely dissolved;

[0054] (2) Then add penetrating agent, copper corrosion inhibitor, aluminum corrosion inhibitor and steel rust inhibitor to the production kettle in sequence, keep the temperature of the production kettle at 20-40°C, and fully stir for 30-60 minutes to form a uniform transparent solution;

[0055] (3) Finally, add solubilizer, nonionic surfactant and mixed surfactant to the production kettle, keep the temperature of the production kettle at 20-40°C, and stir thoroughly for 30-60 minutes until it is uniform and transparent, which is neutral silicone oil and silicone grease cleaning agent.

[0056] Th...

Embodiment 1

[0058] The raw materials of the embodiments of the present invention are all commercially available raw materials.

[0059] A kind of neutral silicone oil and silicone grease cleaning agent, its composition is (taking 1000g neutral silicone oil and silicone grease cleaning agent as example):

[0060]

[0061]

[0062] The preparation method of above-mentioned neutral silicone oil and silicone grease cleaning agent, the steps are as follows:

[0063] ⑴Put an appropriate amount of water into the production kettle, raise the temperature to 20-40°C, add the production amount of sodium carbonate and methyl glycine diacetic acid, keep the temperature at 20-40°C, and stir for 20-30 minutes to ensure that they are completely dissolved;

[0064] (2) Then add the formula JFC-2G, methyl benzotriazole, DK-80, triethanolamine borate, amidocarboxylic acid rust inhibitor to the production kettle in sequence, keep the temperature of the production kettle at 20-40°C, fully Stir for 30-6...

Embodiment 2

[0067] A kind of neutral silicone oil and silicone grease cleaning agent, its composition is (taking 1000g neutral silicone oil and silicone grease cleaning agent as example):

[0068]

[0069] The preparation method of the above-mentioned neutral silicone oil and silicone grease cleaning agent The preparation method, the steps are as follows:

[0070] ⑴Put water into the production kettle, heat up to 20-40°C, add potassium carbonate, sodium benzoate and methyl glycine diacetic acid, keep the temperature at 20-40°C, stir for 20-30 minutes to ensure that the builder and complexing agent are completely dissolve;

[0071] (2) Then add maleic acid di-sec-octyl sodium sulfonate, tolyltriazole, 2-mercaptobenzothiazole, anycoat TM-3, monoethanolamine borate, amide Carboxylic acid anti-rust agent, keep the temperature of the production kettle at 20-40°C, and stir thoroughly for 30-60 minutes to form a uniform and transparent solution;

[0072] (3) Finally, add ethoquad c / 25, poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com