Necteromyces rattus and method for treating high-ammonia-nitrogen biogas slurry by using necteromyces rattus to produce single cell protein

A technology for honey yeast and biogas slurry, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as secondary pollution and waste of resources, and achieve the effects of good growth, convenient operation and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment one: the screening of bacterial strain

[0048] 1. The present invention has tested dozens of strains that may be used in the treatment of high-ammonia nitrogen biogas slurry. In this embodiment, 14 representative strains are selected for display. The names, sources and culture conditions of each strain are as follows: Table 1 shows.

[0049] Table 1 shows the status of each strain

[0050]

[0051]

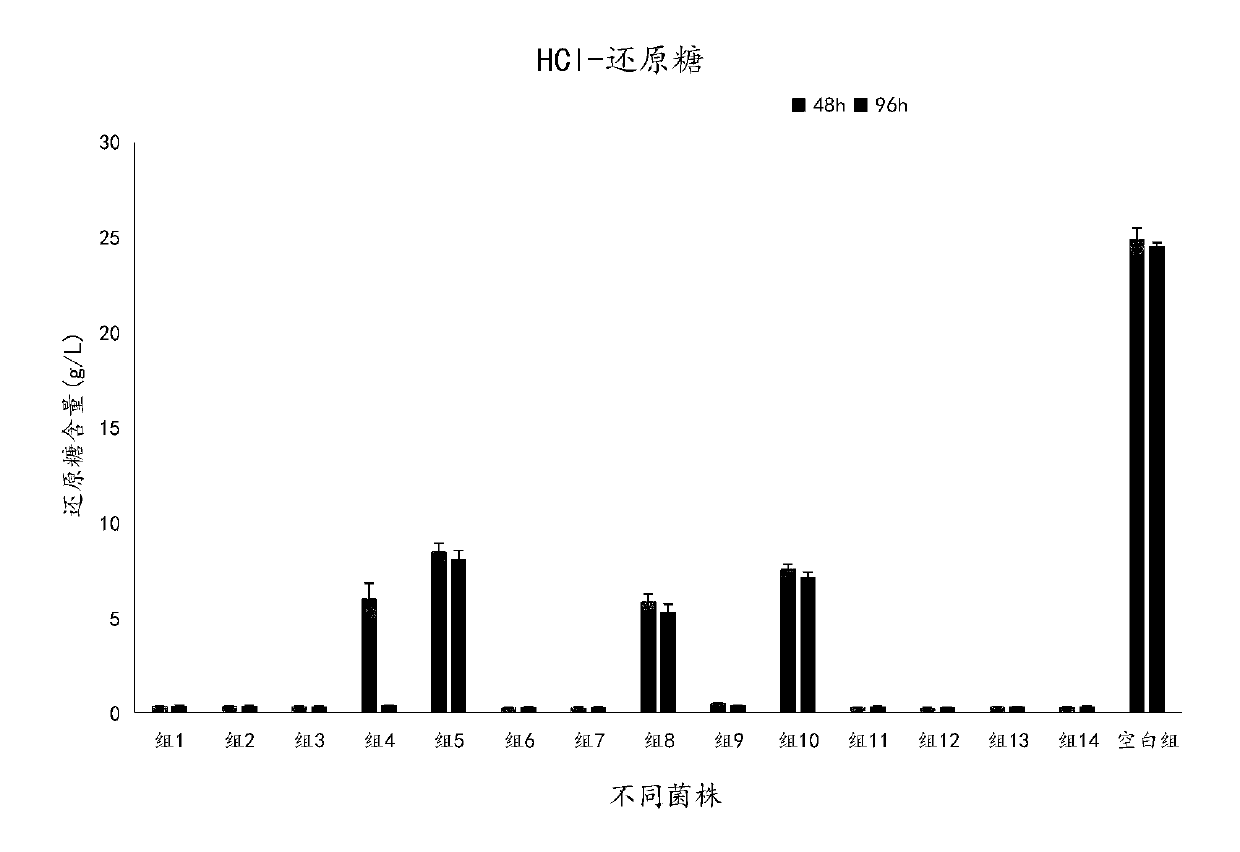

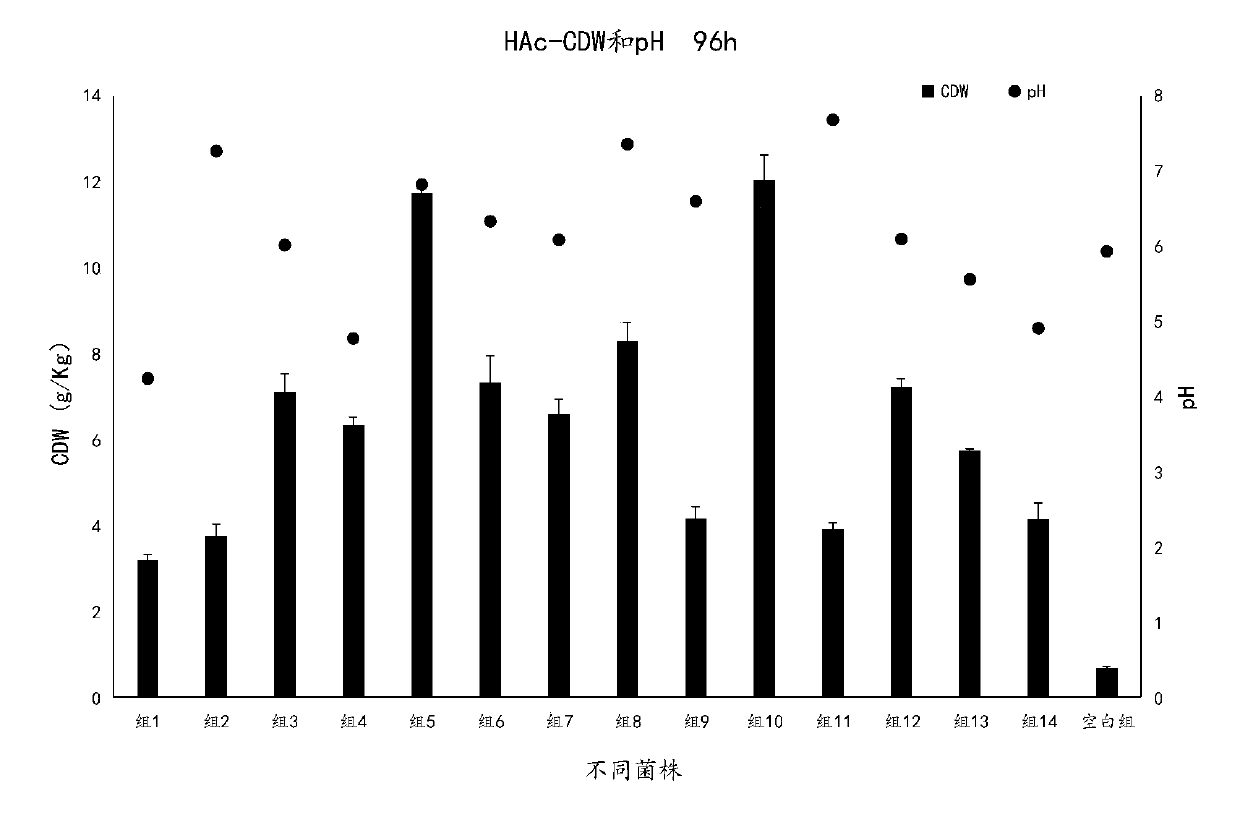

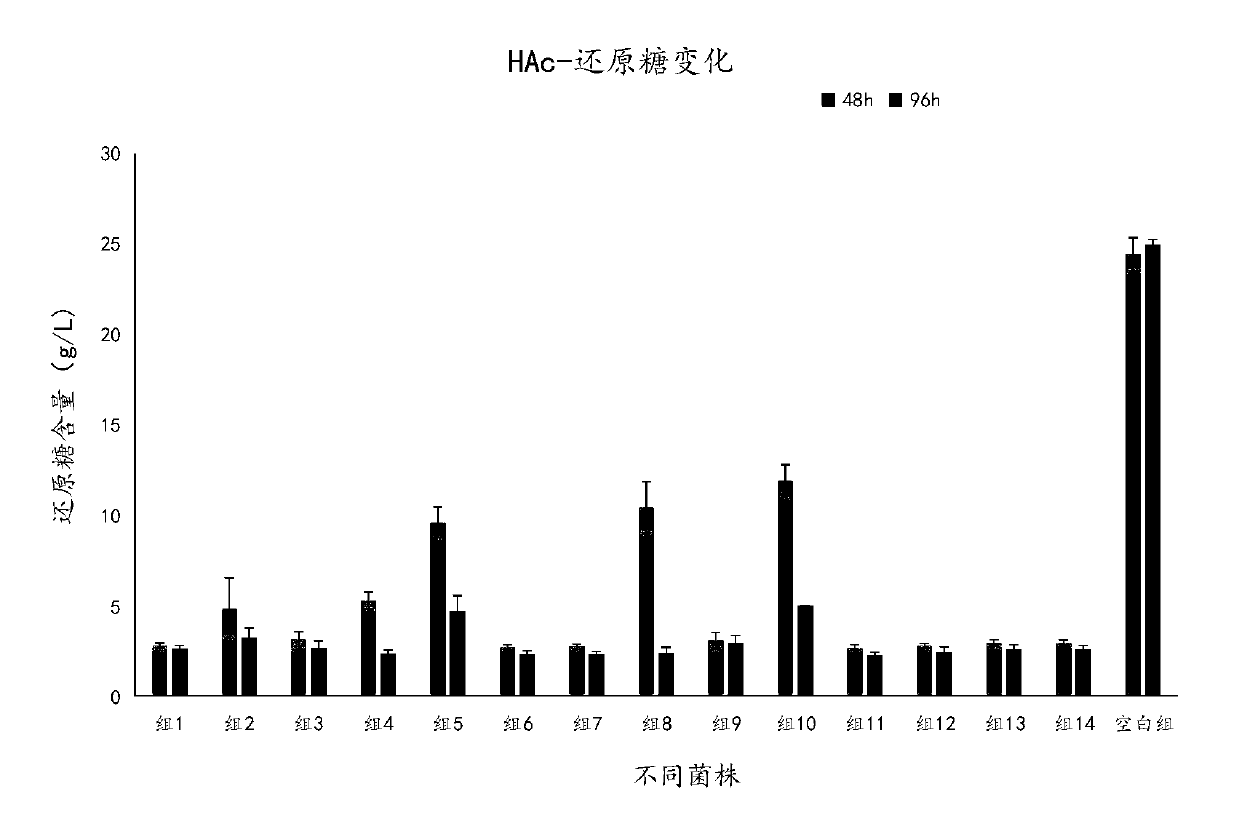

[0052]2. Display of the growth of each strain in chicken manure biogas slurry medium. The 14 kinds of bacteria in Table 1 were inoculated into the chicken manure biogas slurry medium with an ammonia nitrogen content of 1000mg / L (the ammonia nitrogen content was determined using Nessler's reagent photometry), using glucose to adjust C:N=10:1, using HCl Adjust the pH to 7.0, and set 3 parallels in each group. Under the same conditions and the same medium, no strain was used as the blank control group (CK). When cultured to 2 days and 4 days, the culture ...

Embodiment 2

[0068] Example 2: Obtaining, Purifying and Identification of Honey Yeast Strains

[0069] A sample of chicken manure from a chicken farm in Shandong Province was put into a conical flask with 80 mL of sterile water, and cultured on a shaker at 160 rpm at 28 °C. After culturing for 12 hours, the concentration of 10 1 ~10 7 gradient dilution. Choose a dilution of 10 6 and 10 7 Dilutions were spread on solid yeast medium for more than three times. After culturing for 24 hours, pick a single colony with an inoculation loop, and then isolate and purify a single colony by streaking on a plate. Repeatedly pick a single colony and separate and purify it more than three times until the colony has the same shape, and the purified strain is obtained by microscopic examination, and finally transferred to the test tube of solid yeast medium.

[0070] The isolated and purified strains were observed under a microscope, and the results were as follows: Figure 11 Shown: the bacterium i...

Embodiment 3

[0072] Example 3: Effect of adding different carbon sources on fermentation

[0073] Select No. 5 Cha's culture medium as the selection medium, replace the carbon source (glucose) therein with xylose, sodium lactate, sodium acetate, sucrose containing xylose, sodium lactate, sodium acetate, sucrose (the same amount of carbon source specifically refers to equimolar quality C). The cell concentration was 0.5×10 10 Take 2.5ml of CFU / mL honey yeast seed solution (ie 4% inoculum size) and inoculate them into the above-mentioned No. 5 Chapei medium containing different carbon sources, and cultivate them at 30°C. parallel. It should be noted that the inoculation mentioned in the whole text refers to the inoculation of microorganisms grown to the logarithmic phase, and the % of the inoculum amount refers to the percentage of the volume of the bacteria to the volume of the inoculation substrate. Unless otherwise specified in the full text, the inoculation volume is the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com