Selenium-rich lactic acid bacteria preparation and preparation method thereof

A technology of lactic acid bacteria and preparations, applied in the directions of biochemical equipment and methods, microorganism-based methods, bacteria, etc., can solve problems such as limited guiding significance, and achieve the effect of increasing the content of selenium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

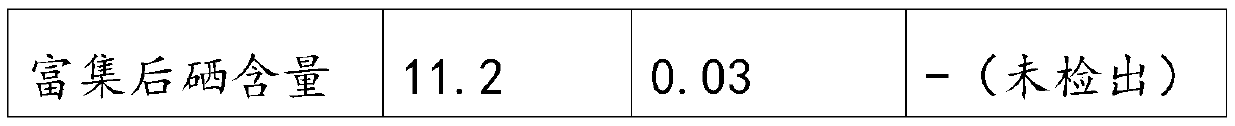

Embodiment 1

[0029] A preparation method for selenium-enriched lactic acid bacteria preparation, comprising the following steps:

[0030] (1) Activated strains: Inoculate the cryopreserved Lb.plantarum ST-III strains in MRS liquid medium, culture anaerobically at 37°C for 18-22 hours, subculture 2-3 times in a cycle, and obtain bacterial cultures Wherein the composition of MRS liquid medium is as follows: 10g peptone, 10g beef extract, 5g yeast extract powder, 20g glucose, 2g dipotassium hydrogen phosphate, 5g sodium acetate, 2g trisodium citrate, 1g Tween 80, 200mg magnesium sulfate, 54mg of manganese sulfate and 1000mL of distilled water, adjust the pH to 6.5, and sterilize at 121°C for 15 minutes;

[0031] (2) Preparation of Enshi selenium-enriched tea extract: Weigh 2g of Enshi selenium-enriched tea sample, add Soak in 100mL of pure water for 10min, take the supernatant, filter it through a 0.44μm sterile filter membrane, and get Enshi selenium-enriched tea extract;

[0032] (3) Con...

Embodiment 2

[0040] A preparation method for selenium-enriched lactic acid bacteria preparation, comprising the following steps:

[0041] (1) Activated strains: Inoculate the cryopreserved Lb.plantarum ST-III strains in MRS liquid medium, culture anaerobically at 37°C for 18-22 hours, subculture 2-3 times in a cycle, and obtain bacterial cultures Wherein the composition of MRS liquid medium is as follows: 10g peptone, 10g beef extract, 5g yeast extract powder, 20g glucose, 2g dipotassium hydrogen phosphate, 5g sodium acetate, 2g trisodium citrate, 1g Tween 80, 200mg magnesium sulfate, 54mg of manganese sulfate and 1000mL of distilled water, adjust the pH to 6.5, and sterilize at 121°C for 15 minutes;

[0042] (2) Preparation of ordinary green tea (Liu'an Guapian) extract: Weigh 2g of ordinary green tea (Liu'an Guapian) sample, add Soak in 100mL of pure water for 10min, take the supernatant, and filter through a 0.44μm sterile filter membrane to obtain ordinary green tea extract;

[0043...

Embodiment 3

[0049] A preparation method for selenium-enriched lactic acid bacteria preparation, comprising the following steps:

[0050] (1) Activated strains: freeze-preserved Lb.plantarum ATCC14917 strains (Whole-genome sequencing reveals the mechanisms for evolution of streptomycin resistance in Lactobacillus plantarum. Zhang F, Gao J, Wang B, Huo D, Wang Z, Zhang J, Shao Y.JDairy Sci.2018Apr; 101(4):2867-2874) was inoculated in MRS liquid medium, cultured anaerobically at 37°C for 18-22 hours, and subcultured 2-3 times in a cycle to obtain bacterial cultures; The composition of MRS liquid medium is as follows: 10g peptone, 10g beef extract, 5g yeast extract powder, 20g glucose, 2g dipotassium hydrogen phosphate, 5g sodium acetate, 2g trisodium citrate, 1g Tween 80, 200mg magnesium sulfate, 54mg sulfuric acid Manganese and 1000mL distilled water, adjust the pH to 6.5, and sterilize at 121°C for 15min;

[0051] (2) Preparation of Enshi selenium-enriched tea extract: Weigh 2g of Enshi s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com