Preparation method, product and application of solar energy-assisted air water production material

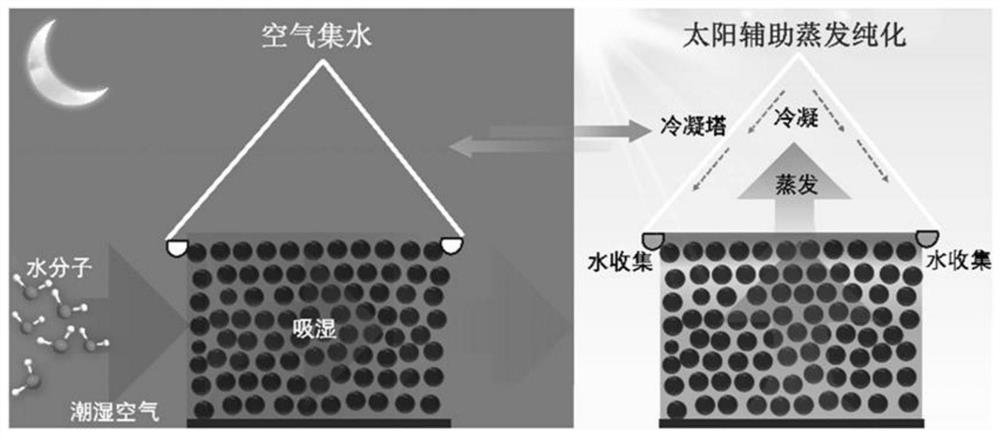

A technology for assisting air and solar energy, applied in the directions of solar thermal energy, solar thermal power generation, solar thermal collectors, etc., can solve the problems of cumbersome preparation process of air water maker and secondary water pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Such as figure 1 Shown, the preparation schematic diagram of the solar energy assisted air water production material prepared in this embodiment;

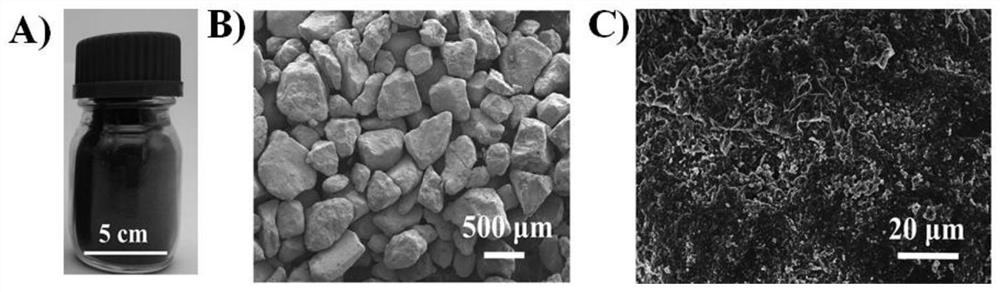

[0052] (1) Set the volume to 500cm 3 Sea sand particles with a roughness of 1% and a particle size of 100-500 μm were immersed in a sodium hydroxide solution with a concentration of 20 mg / mL for 10 minutes, and then dried at 25 ° C for 2 hours to obtain the treated sea sand particles. sand particle A;

[0053] (2) Immerse sea sand particles A in 5mg / ml ferric chloride aqueous solution, soak at 30°C for 0.5h, and then dry at 20°C for 3h to obtain treated sea sand particles B;

[0054] (3) Immerse the sea sand particles B in a chloroform solution of 2.5 mg / mL polypyrrole with a molecular weight of 12000, soak at 50°C for 9 hours, and then dry at 20°C for 3 hours to obtain the treated sea sand particles C ;

[0055] (4) The sea sand particles C in step C were immersed in 5 mg / ml ferric chloride aqueous solution, soaked at 3...

Embodiment 2

[0064] (1) Set the volume to 500cm 3 Sea sand particles with a roughness of 1% and a particle size of 100-500 μm were immersed in a potassium hydroxide solution with a concentration of 20 mg / mL for 10 minutes, and then dried at 25 ° C for 2 hours to obtain the treated sea sand particles. sand particle A;

[0065] (2) Immerse sea sand particles A in 5mg / ml ferric chloride aqueous solution, soak at 30°C for 0.5h, and then dry at 20°C for 3h to obtain treated sea sand particles B;

[0066] (3) Immerse the sea sand particles B in a chloroform solution of 2.5 mg / mL polypyrrole with a molecular weight of 12000, soak at 50°C for 9 hours, and then dry at 20°C for 3 hours to obtain the treated sea sand particles C ;

[0067] (4) The sea sand particles C in step C were immersed in 5 mg / ml ferric chloride aqueous solution, soaked at 30° C. for 2 hours, and then dried at 20° C. for 3 hours to obtain the solar-assisted air-based water production material.

[0068] The properties of the ...

Embodiment 3

[0072] (1) Set the volume to 500cm 3 Sea sand particles with a roughness of 1% and a particle size of 100-500 μm were immersed in a sodium hydroxide solution with a concentration of 20 mg / mL for 10 minutes, and then dried at 25 ° C for 2 hours to obtain the treated sea sand particles. sand particle A;

[0073] (2) Immerse sea sand particles A in a 5 mg / ml potassium permanganate aqueous solution, soak at 30°C for 0.5h, and then dry at 20°C for 3h to obtain treated sea sand particles B;

[0074] (3) Immerse the sea sand particles B in a chloroform solution of 2.5 mg / mL polypyrrole with a molecular weight of 12000, soak at 50°C for 9 hours, and then dry at 20°C for 3 hours to obtain the treated sea sand particles C ;

[0075] (4) The sea sand particles C in step C were immersed in 5 mg / ml ferric chloride aqueous solution, soaked at 30° C. for 2 hours, and then dried at 20° C. for 3 hours to obtain the solar-assisted air-based water production material.

[0076] The properties ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com