A kind of capsule wall degradable small molecule antioxidant microcapsule emulsion and its preparation method and application

An anti-aging agent and microcapsule technology, which is applied in the field of small molecule anti-aging agent microcapsule emulsion and its preparation, can solve the problems of aggregation instability, narrow application range, high cost, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

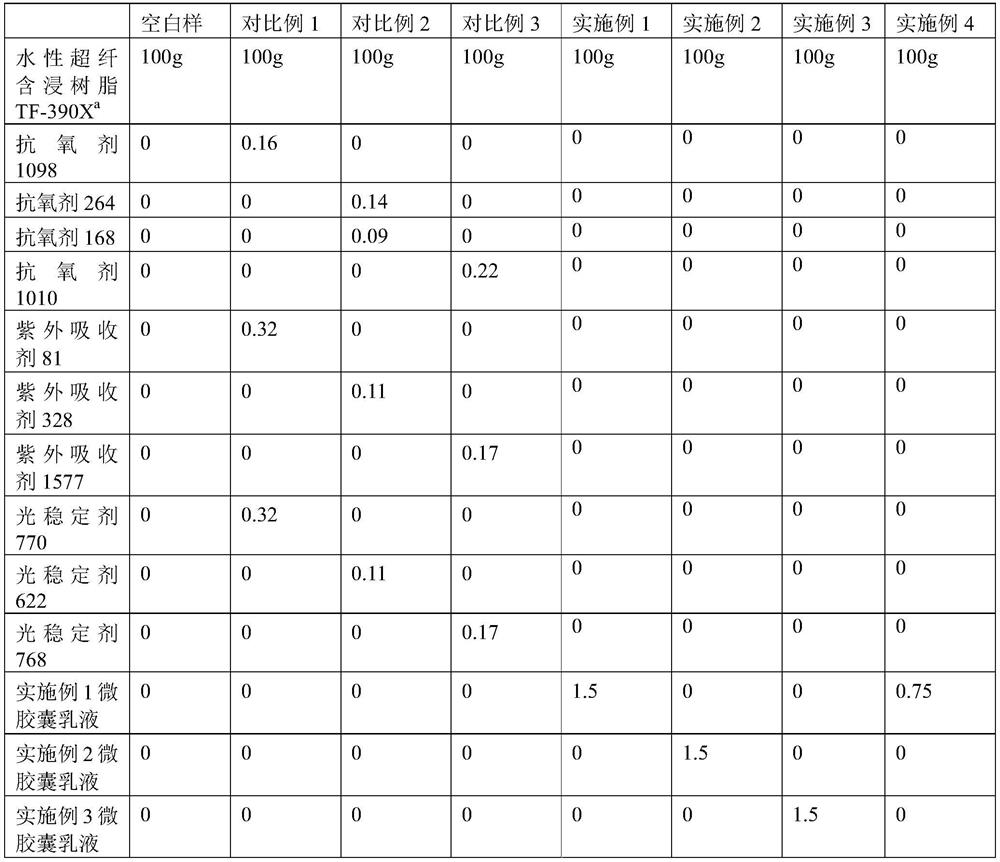

Examples

Embodiment 1

[0025] Weigh 80g of poly-1,6-hexanediol adipate with a molecular weight of 2000, add it to a four-necked flask equipped with a stirring paddle and nitrogen protection, heat up to 120°C, vacuum dehydrate for 30min, cool down to 55°C and add 33.6g mass parts of HMDI, stirred evenly under the protection of nitrogen, reacted at 85°C for 1h, then added 0.01g mass portion of stannous octoate as a catalyst, and reacted at 60°C for 3h to obtain a clear and transparent reactant A, adding 5.3 g dimethylol propionic acid, 1.5g neopentyl glycol, 20g methyl ethyl ketone, reacted for 2h at 75°C; cooled to 45°C to obtain a clear and viscous shell resin prepolymer B, which was re-produced according to step 1) Reactant A of 32g mass parts, after it is mixed with 13g HMDI homogeneously as dissolution medium, add 28.8g antioxidant 1098 (N,N'-bis-(3-(3,5-di-tert-butyl-4 hydroxyl Phenyl) propionyl) hexamethylene diamine), 57.6g UV absorber CHIMASSORB 81, 57.6g light stabilizer TINUVIN 770, under s...

Embodiment 2

[0027]Weigh 120g of poly(1,4-butylene adipate) with a molecular weight of 3000, add it into a four-necked flask equipped with a stirring paddle and nitrogen protection, heat up to 100°C, vacuum dehydrate for 90min, cool down to 75°C and add 28.7g parts by mass of IPDI, stirred evenly under the protection of nitrogen, reacted at 90°C for 0.5h, then added 0.05g parts by mass of dibutyltin dilaurate as a catalyst, reacted at 85°C for 2.5h, and obtained 148.7g of clear and transparent Reactant A, add 4.5g dimethylol propionic acid, 2g 1,4-butanediol, 30g acetone, react at 75°C for 2h; cool down to 45°C to obtain clear and viscous shell resin prepolymer B, press Step 1) make reactant A of 47g mass parts again, after it is mixed with 5.4g IPDI homogeneously as dissolution medium, add 40g antioxidant (wherein antioxidant 264 2,6-di-tert-butyl-4-methyl Base phenol 25g, antioxidant 168 tris (2,4-di-tert-butylphenyl) phosphite 15g), 20g UV absorber TINUVIN 328, 20g light stabilizer TINU...

Embodiment 3

[0029] Weigh 40g of polyethylene adipate with a molecular weight of 1000, add it to a four-necked flask equipped with a stirring paddle and nitrogen protection, heat up to 120°C, vacuum dehydrate for 60min, and add 16g parts by mass of TDI, stirred evenly under the protection of nitrogen, reacted at 85°C for 0.5h, then added 0.01g of dibutyltin dilaurate as a catalyst, reacted at 85°C for 2.5h, obtained a clear and transparent reactant A, added 4g of hexyl Diol, 10g acetone, react at 75°C for 2h; cool down to 45°C, add 2.5g sodium ethylenediaminoethanesulfonate to obtain a clear and viscous shell resin prepolymer B, and then prepare it according to step 1) The reactant A of 20g mass parts, after it is mixed with 4.2g IPDI as dissolution medium, add 20g antioxidant 1010 (tetrakis (β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid ) pentaerythritol ester), 15g of UV absorber TINUVIN 1577, 15g of light stabilizer 765, heated up to 65°C under stirring, and after fully dissolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com