Molybdenum carbide nanorod for catalyst and preparation method and application thereof

A technology of nanorods and molybdenum carbide, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, carbides, etc., can solve problems such as unsuitability for industrial production, differences in catalyst verticality, and reduced catalytic efficiency. Transport, increase reaction kinetics, increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing molybdenum carbide nanorods for catalysts, comprising the following steps:

[0036] Ultrasonic disperse molybdenum trioxide and hypoxanthine in deionized water at a molar ratio of 1:1 to obtain a dispersion. The mass concentration of molybdenum trioxide in the dispersion is 3.33g / L, and the resulting dispersion is put into a reaction kettle , hydrothermal reaction at 110°C for 12 hours, then naturally cooled to room temperature, centrifuged, and the obtained product was washed three times with deionized water and ethanol, respectively, and then vacuum-dried at 70°C for 6 hours to obtain precursor nanorods. The obtained precursor nanorods were heated to 850°C at a heating rate of 5°C / min in a nitrogen atmosphere, calcined at 850°C for 2 hours, and the nitrogen flow rate was 200 sccm, and then naturally cooled to room temperature to obtain molybdenum carbide nanorods.

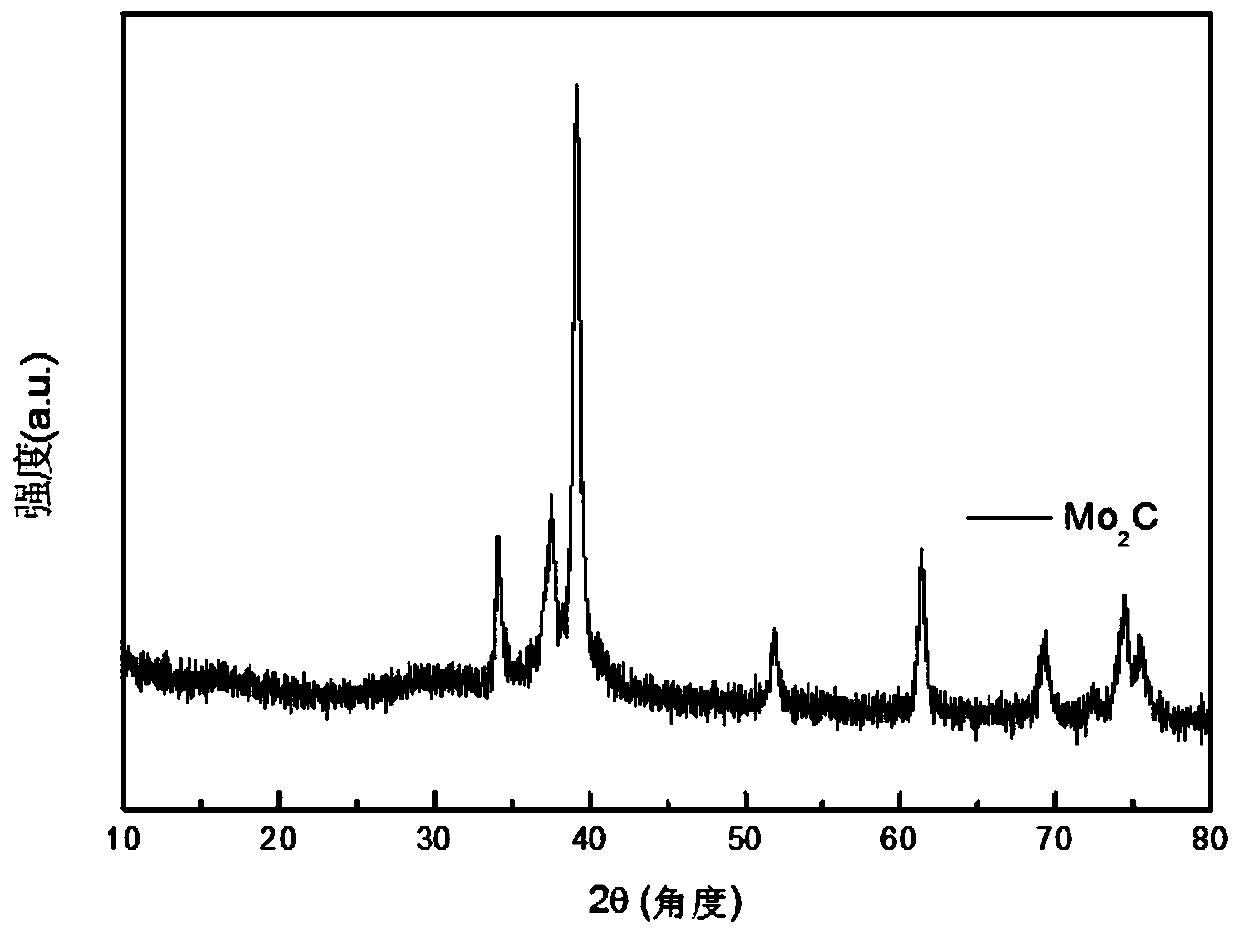

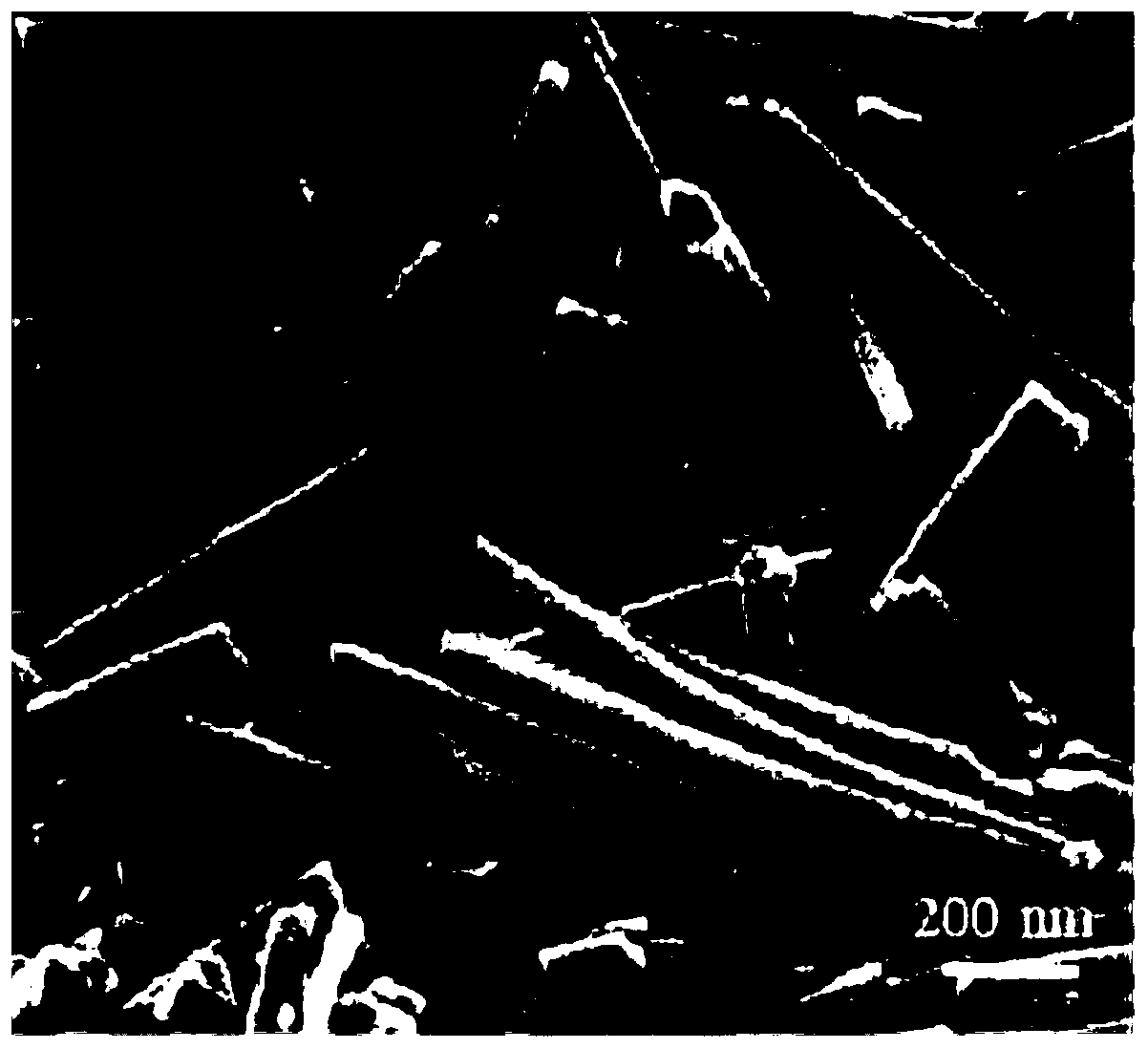

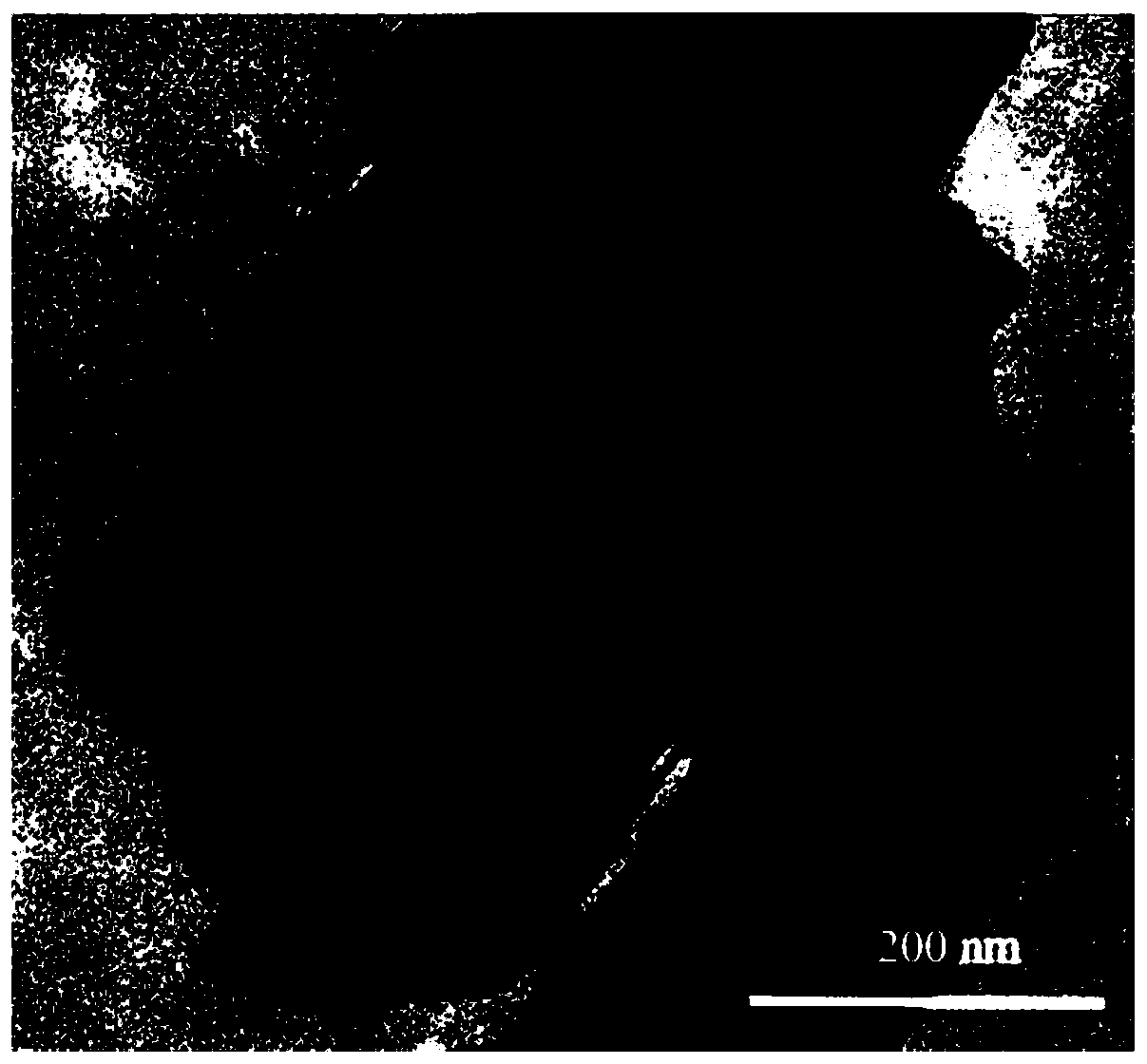

[0037] The X-ray diffraction pattern of the molybdenum carbide nanorod prepared ...

Embodiment 2

[0044] A method for preparing molybdenum carbide nanorods for catalysts, comprising the following steps:

[0045] Ultrasonic disperse molybdenum trioxide and hypoxanthine in deionized water at a molar ratio of 1:1 to obtain a dispersion. The mass concentration of molybdenum trioxide in the dispersion is 3.33g / L, and the resulting dispersion is put into a reaction kettle , hydrothermal reaction at 110°C for 12 hours, then naturally cooled to room temperature, centrifuged, and the resulting product was washed three times with deionized water and ethanol, respectively, and then vacuum-dried at 70°C for 6 hours to obtain precursor nanorods. The obtained precursor nanorods were heated to 750°C at a heating rate of 5°C / min in a nitrogen atmosphere, calcined at 750°C for 2 hours, and the nitrogen flow rate was 200 sccm, and then naturally cooled to room temperature to obtain molybdenum carbide nanorods.

Embodiment 3

[0047] A method for preparing molybdenum carbide nanorods for catalysts, comprising the following steps:

[0048] Ultrasonic disperse molybdenum trioxide and hypoxanthine in deionized water at a molar ratio of 1:0.72 to obtain a dispersion. The mass concentration of molybdenum trioxide in the dispersion is 3.33g / L, and the resulting dispersion is placed in a reactor , hydrothermal reaction at 110°C for 12 hours, then naturally cooled to room temperature, centrifuged, and the resulting product was washed three times with deionized water and ethanol, respectively, and then vacuum-dried at 70°C for 6 hours to obtain precursor nanorods. The obtained precursor nanorods were heated to 750°C at a heating rate of 5°C / min in a nitrogen atmosphere, calcined at 750°C for 2 hours, and the nitrogen flow rate was 200 sccm, and then naturally cooled to room temperature to obtain molybdenum carbide nanorods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com