Method for preparing zinc cobaltate nanoparticles by reverse microemulsion method

A nano-zinc cobaltate and solution technology, applied in nanotechnology, chemical instruments and methods, cobalt compounds, etc., can solve the problems of reproducibility of introduced impurities, poor product crystallinity, etc., and achieve high phase composition purity and crystallinity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

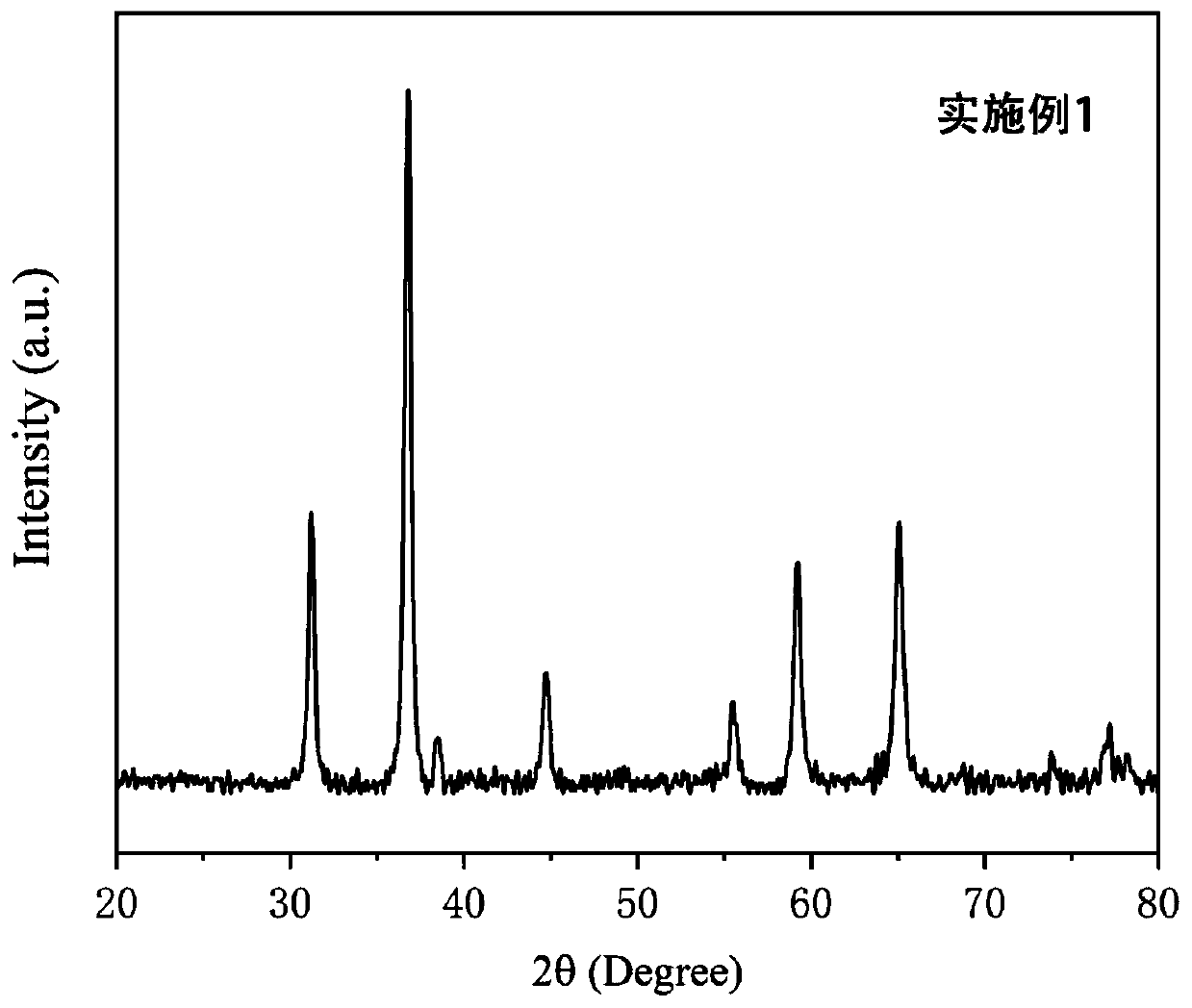

Embodiment 1

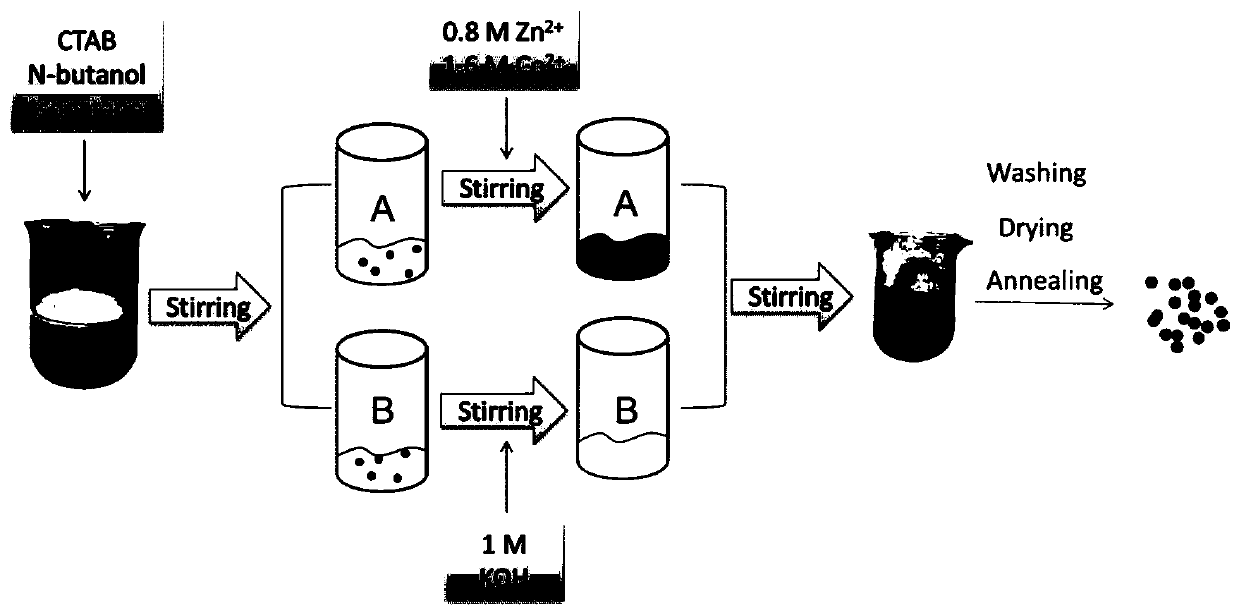

[0022] The preparation method of this embodiment is as figure 1 shown, including the following steps:

[0023] (1) Measure 10g of isooctane and 4g of n-butanol into a beaker, put it into the rotor, and place it on a magnetic stirrer for continuous stirring. At the same time, weigh 3 g of cetyltrimethylammonium bromide, slowly Pour into the solution, and continue to stir until the solution has no obvious large particles;

[0024] (2) Divide the solution into two parts and mark them as solution A and solution B respectively. At this time, the solution is relatively turbid;

[0025] (3) Configure 1 M KOH solution, add 6 mL dropwise to the A solution obtained in step (2), and keep stirring until the solution becomes transparent and clear;

[0026] (4) Weigh zinc nitrate and cobalt nitrate and add them into the beaker according to the molar ratio of 1:2. The concentration of zinc nitrate is 0.8 mol / L, and the concentration of cobalt nitrate is 1.6 mol / L. Add 1.5 mL to the B solu...

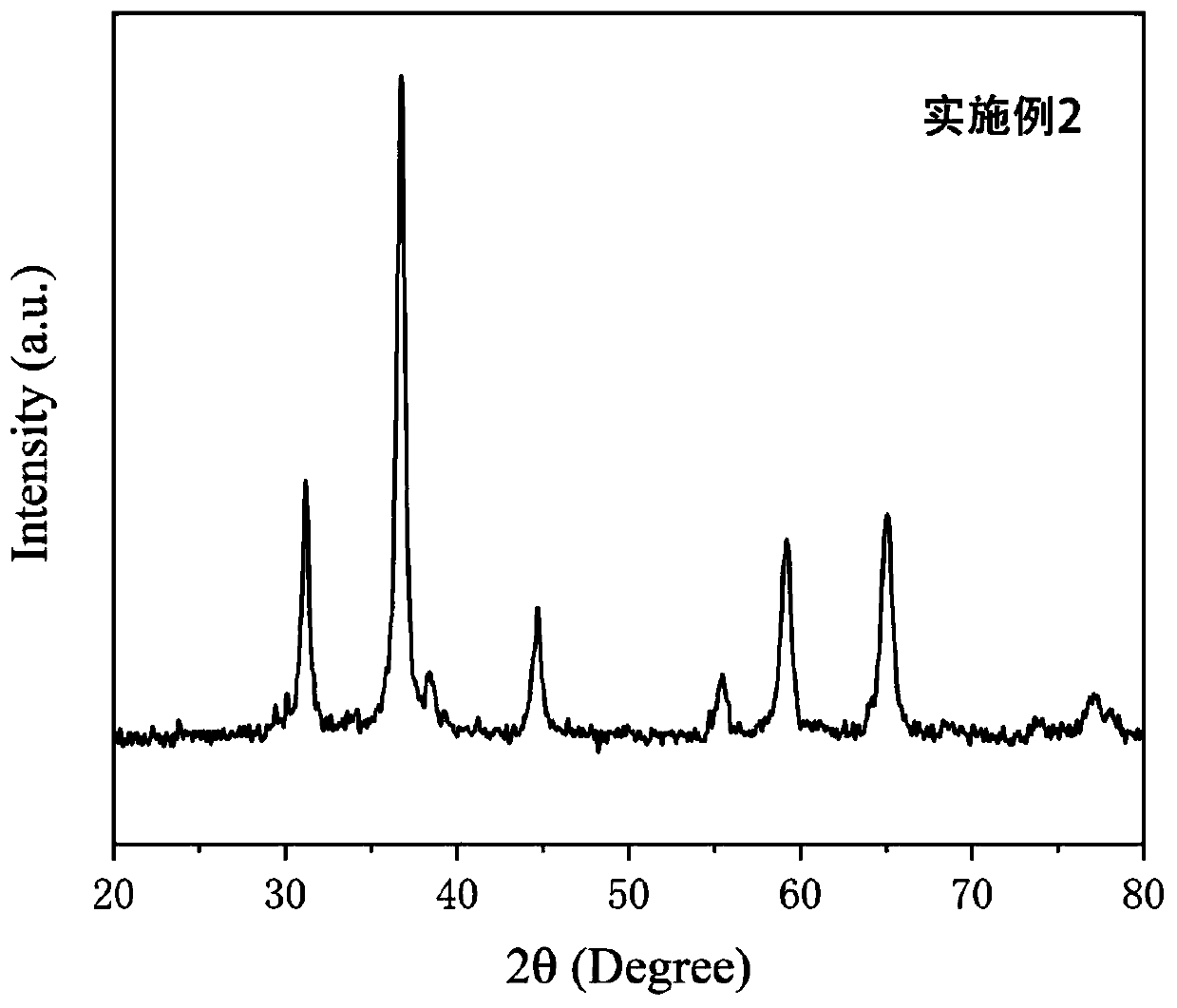

Embodiment 2

[0032] The preparation method of the present embodiment comprises the following steps:

[0033] (1) Measure 8g of isooctane and 4g of isopropanol into a beaker, put it into the rotor, and place it on a magnetic stirrer for continuous stirring. At the same time, weigh 3 g of cetyltrimethylammonium bromide, slowly Pour into the solution, and continue to stir until the solution has no obvious large particles;

[0034] (2) Divide the solution into two parts and mark them as solution A and solution B respectively. At this time, the solution is relatively turbid;

[0035] (3) Configure 1.5 M NaOH solution, add 4 mL dropwise to the A solution obtained in step (2), and keep stirring until the solution becomes transparent and clear;

[0036] (4) Weigh zinc nitrate and cobalt nitrate into the beaker according to the molar ratio of 1:2, and prepare the concentration of zinc nitrate to be 0.8mol / L and the concentration of cobalt nitrate to be 1.6mol / L. Take 1.2mL and add it to the B sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com