Isonaringin extraction and separation process

A technology of isonaringin and process, which is applied in the field of extraction and separation technology of isnaringin, can solve the problems of no report on isonaringin extraction and separation process, no report on refining, etc., and achieves improved commercial value, low cost, raw material easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

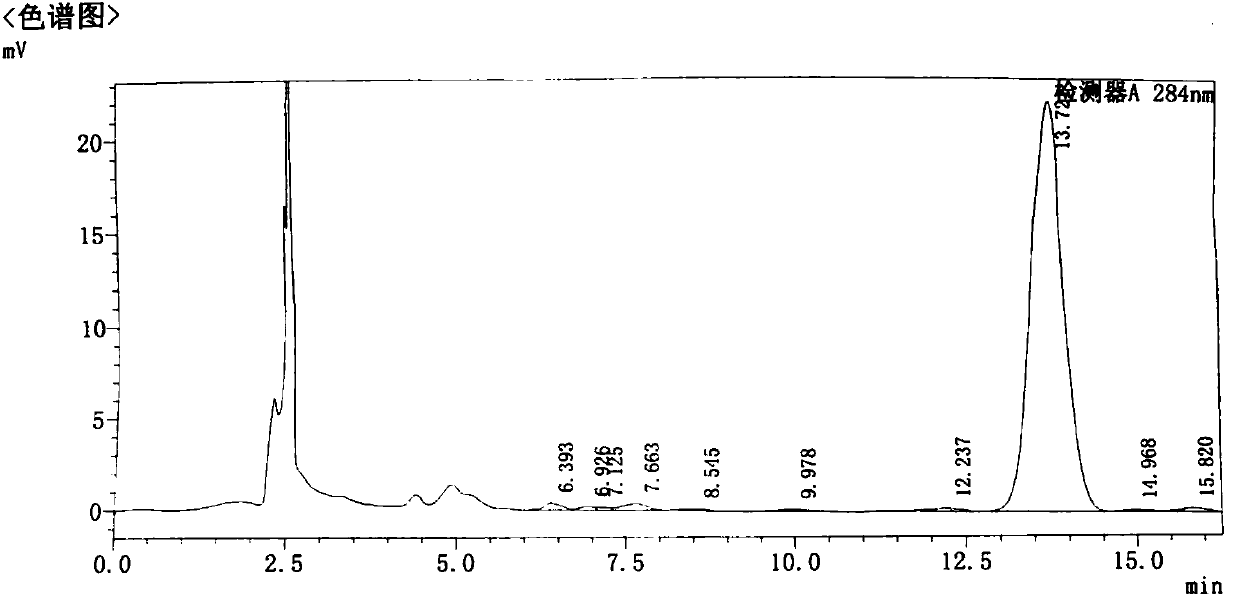

Image

Examples

Embodiment 1

[0045]Take young citrus fruit, dry until the water content is lower than 15%, crush it through a 30-mesh sieve after drying, take 200g of young citrus fruit powder, add 1200mL of 73% ethanol aqueous solution, then adjust the pH to 9 with 20% NaoH solution, and reflux at 60°C Extract for 2 hours, collect the filtrate by filtration, and then reflux the filtrate with 1000mL of 73% ethanol aqueous solution with a pH of 9 at 60°C for 2 times, each time for 1 hour, combine the filtrate three times for a total of 3000mL, recover ethanol with a rotary evaporator to obtain 600mL of flavonoids and concentrate liquid; the citrus flavonoids concentrated solution was adjusted to ph with hydrochloric acid to be 8, stirred evenly, left to stand for 3h and then suction filtered, and the mother liquor was taken, and continued to be adjusted to ph with hydrochloric acid to be 6.5, after stirring, crystallization for 8h and suction filtration to obtain 8g of isonaringin crude product (Crude produ...

Embodiment 2

[0048] Such as figure 1 , take young citrus fruit, dry until the water content is lower than 15%, crush it through a 30-mesh sieve after drying, take 200g of young citrus fruit powder, add 1200mL of 75% ethanol aqueous solution, and then adjust the pH to 9.5 with 20% NaoH solution; Extract under reflux for 2 hours, and collect the filtrate by filtration; the filter material is refluxed again with 1000 mL of 73% ethanol aqueous solution with a pH of 9.5 at 75 ° C for 2 times, each time for 1 hour, and the filtrates are combined for a total of 3100 mL, and the ethanol is recovered by a rotary evaporator to obtain 650 mL Concentrated flavonoids: use hydrochloric acid to adjust the ph of citrus flavonoids to 8, stir evenly, let stand for 3 hours, then filter with suction, take the mother liquor, continue to use hydrochloric acid to adjust the pH to 6.5, stir evenly, crystallize for 8 hours, and then filter with suction to obtain 6g of isopomelo peel Glycoside crude product (crude ...

Embodiment 3

[0055] Take young citrus fruit, dry until the water content is lower than 15%, crush it through a 25-mesh sieve after drying, take 200g of young citrus fruit powder, add 1200mL of 70% ethanol aqueous solution, then adjust the pH to 10 with 20% NaoH solution, and reflux at 75°C Extract for 2 hours, collect the filtrate by filtration, and then reflux the filtrate with 1000mL of 70% ethanol aqueous solution with a pH of 10 at 75°C for 2 times, each time for 1 hour, combine the filtrate three times for a total of 3000mL, recover ethanol with a rotary evaporator to obtain 600mL of flavonoids and concentrate liquid; the citrus flavonoid concentrated solution is adjusted to 7.5 with hydrochloric acid, stirred evenly, and suction filtered after standing for 3 hours, and the mother liquor was taken, and continued to be adjusted to 6.5 with hydrochloric acid, and the crystallization after stirring for 8 hours was obtained by suction filtration to obtain 8g of isonaringin crude product (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com