Manufacturing method of target material assembly

A production method and target technology, which are applied in the direction of manufacturing tools, metal material coating process, ion implantation plating, etc., can solve the problems of non-wetting, physical property mismatch, metallurgical incompatibility, etc., and achieve good wetting The effect of high performance and fluidity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

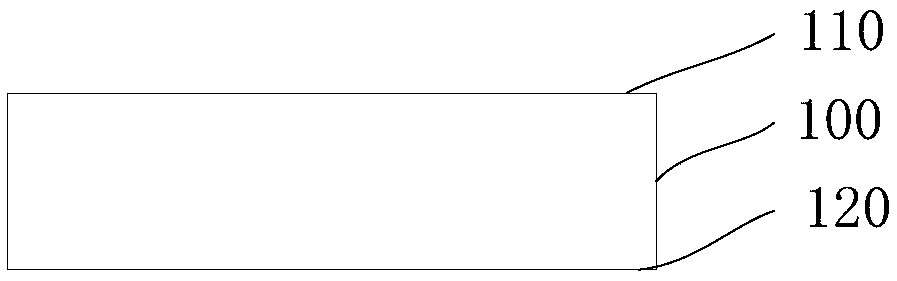

[0022] At present, in the production process of target components, electroplating process or vacuum evaporation process is usually used to form a nickel layer on the target welding surface of the silica target, and then the silica target and the metal back are bonded by hot fusion welding. The plates are welded together to form the target assembly.

[0023] After analysis, the inventor found that the target assembly prepared by the above method of forming the target assembly has poor quality of the nickel layer formed by electroplating, and the bonding force with the silicon dioxide target is small, and it is easy to fall off, resulting in the metal being in the second layer during hot-melt welding. Poor wetting of the silicon oxide surface results in low welding bonding rate and low welding bonding strength between the silicon dioxide target and the metal back plate, which cannot meet the requirements of use.

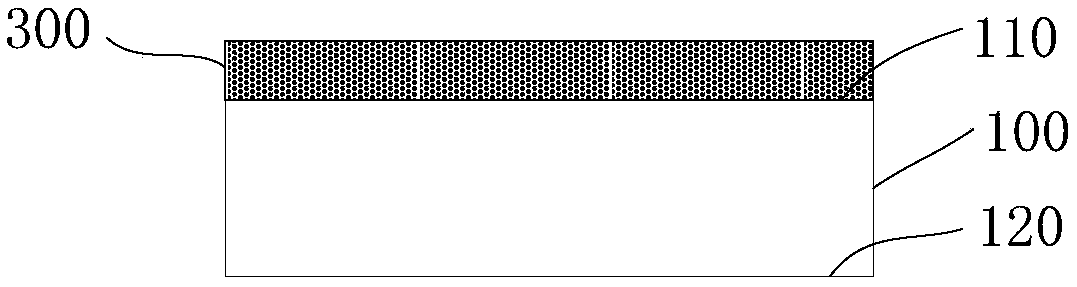

[0024] The inventor found through research that the plasma sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com