Hydrotalcite-loaded palladium catalyst for preparing styrene through selective hydrogenation of phenylacetylene and preparation method thereof and application

A technology for selective hydrogenation and styrene production, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. It can solve the problems of cumbersome preparation process and low catalytic performance. Achieve the effects of simple preparation process, high industrial value and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

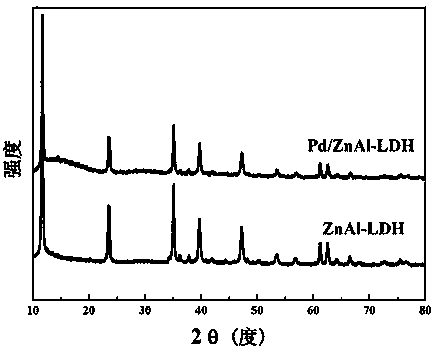

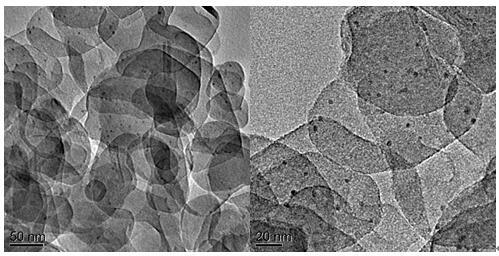

[0035] A. Preparation of ZnAl hydrotalcite

[0036] The hydrotalcite support was prepared by co-precipitation method, and the molar ratio of Zn / Al was 2:1. Prepare 0.08 mol / L Zn(NO 3 ) 2 and 0.04 mol / L Al(NO 3 ) 3 100 mL of mixed salt solution, and 0.56 mol / L CO(NH 2 ) 2 50 mL of weak base solution. At room temperature, the above mixed salt and weak base solution were slowly added dropwise into a three-neck flask filled with 50 mL of deionized water. After the dropwise addition was completed, after stirring for 1 h, the resulting mixed slurry was transferred to a hydrothermal kettle, and reacted at 140° C. for 48 h. After the kettle was taken out and cooled to room temperature, the precipitate was washed with deionized water until the pH of the supernatant was about 7. The obtained precipitate was dried at 60 °C for 6 h, and the powder sample obtained by grinding was ZnAl-LDH.

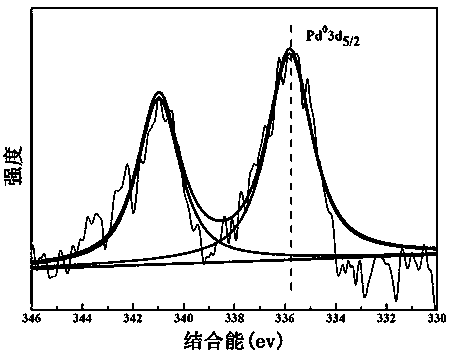

[0037] B1. Preparation of 0.35wt% Pd / ZnAl-LDH

[0038] Weigh 1.0 g of the prepared zinc-a...

Embodiment 2

[0058] A. Preparation of NiAl hydrotalcite

[0059] The hydrotalcite carrier was prepared by co-precipitation method, and the molar ratio of Ni / Al was 2 / 1. Prepare 0.08 mol / L Ni(NO 3 ) 2 and 0.04 mol / L Al(NO 3 ) 3 100 mL of mixed salt solution, and 0.56 mol / L CO(NH 2 ) 2 50 mL of weak base solution. At room temperature, into a three-necked flask filled with 50 mL of deionized water, the mixed salt and weak base solution were slowly added dropwise at the same time. After the dropwise addition was completed, after stirring for 1 h, the resulting mixed slurry was transferred to a hydrothermal kettle, and reacted at 130° C. for 48 h. After the kettle was taken out and cooled to room temperature, the precipitate was washed with deionized water until the pH of the supernatant was about 7. After the obtained precipitate was dried at 60 °C for 8 h, the powder sample obtained by grinding was NiAl-LDH.

[0060] B. Preparation of 0.68wt% Pd / NiAl-LDH

[0061] Weigh 1.0 g of the ...

Embodiment 3

[0063] A. Preparation of NiFe hydrotalcite

[0064]The hydrotalcite carrier was prepared by co-precipitation method, and the molar ratio of Ni / Fe was 2 / 1. Prepare 0.08 mol / L Ni(NO 3 ) 2 and 0.04 mol / L Fe(NO 3 ) 3 100 mL of mixed salt solution, and 0.56 mol / L CO(NH 2 ) 2 40mL of weak base solution. At room temperature, into a three-necked flask filled with 50 mL of deionized water, the mixed salt and weak base solution were slowly added dropwise at the same time. After the dropwise addition was completed, after stirring for 1 h, the resulting mixed slurry was transferred to a hydrothermal kettle, and reacted at 140°C for 48 h. After the kettle was taken out and cooled to room temperature, the precipitate was washed with deionized water until the pH of the supernatant was about 7. After the obtained precipitate was dried at 60 °C for 6 h, the powder sample obtained by grinding was NiFe-LDH.

[0065] B. Preparation of 0.73wt% Pd / NiFe-LDH

[0066] Weigh 1.0 g of the prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com