Method for preparing aquatic animal activated carbon by hydrothermal method

A technology of activated carbon and hydrothermal method, which is applied in the field of activated carbon, can solve the lagging problems of aquatic product processing and comprehensive utilization, and achieve the effects of increasing industrial economic benefits, realizing resource utilization, and improving adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

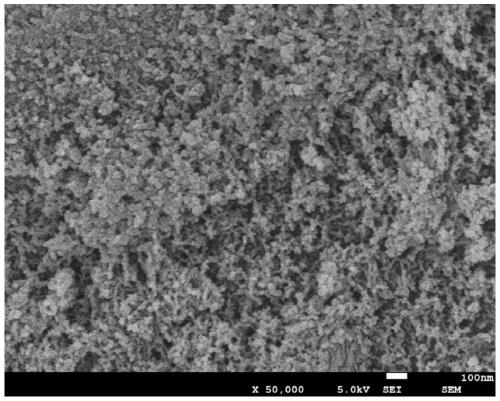

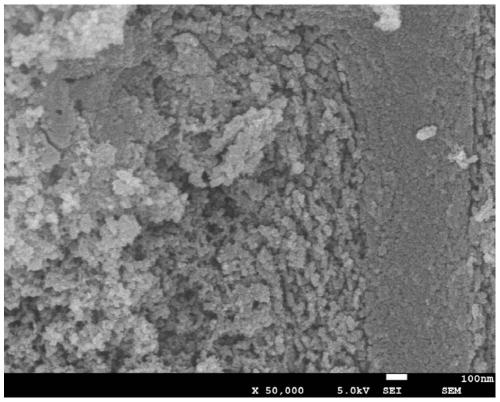

Image

Examples

no. 1 example

[0030] Activated carbon is prepared by using shrimp shells, crab shells, and processed waste from aquaculture shrimp and crabs as animal materials, including the following steps:

[0031] 1. After rinsing with tap water, use deionized water to further rinse waste such as shrimp and crab shells. After cleaning the surface impurities, put them into a grinder while adding a small amount of liquid nitrogen to crush and grind. Among them, the larger crab shells are first cleaned with hard The tools are initially crushed into small pieces and then crushed and ground. The maximum particle size after treatment is not more than 0.3mm.

[0032] 2. Using citric acid as the pore-forming activator, prepare an aqueous solution of citric acid with a mass concentration of 7.5%, mix the ground animal material and the pore-forming activator at a ratio of 1:3, stir evenly and let stand for 25 minutes. Then put it into a closed high-pressure reactor, control the temperature at 180° C., and carry...

no. 2 example

[0035] Adopting fish bone as animal matter material to prepare activated carbon comprises the following steps:

[0036] 1. After rinsing with tap water, use deionized water to further rinse the fish bones. After cleaning the surface impurities, place them in a low-temperature freezer at -10°C for 2 hours, take out the cut pieces, and put them into a pulverizer for crushing. The particles are not larger than 0.2 mm, and a paste biomass is obtained.

[0037] 2. Using acetic acid as the pore-forming activator, it is configured into an aqueous solution of acetic acid with a mass concentration of 5%. The pasty biomass in step (1) is mixed with the pore-forming activator according to the ratio of mass ratio 1:1.5, and the mixture is stirred evenly and left to stand. Set it aside for 20 minutes, then put it into a closed high-pressure reactor, control the temperature at 200°C, and carry out hydrothermal carbonization with a reaction time of 10 hours.

[0038] 3. After the reaction, ...

no. 3 example

[0040] The preparation of activated carbon by using fish scales, fish viscera or waste fish offal processed in aquaculture as animal matter materials includes the following steps:

[0041] 1. After rinsing with tap water, use deionized water to further rinse fish scales, fish viscera, and fish offal. After cleaning the surface impurities, put them into a meat grinder and grind them. The maximum particle size after grinding is not greater than 0.1mm.

[0042] 2. Using ammonium bicarbonate as the pore-forming activator, prepare an aqueous solution of ammonium bicarbonate with a mass concentration of 7.5%, mix the ground animal material with the pore-forming activating solution at a ratio of 1:2, stir well and then let stand After 20 minutes, put it into a closed high-pressure reactor, control the temperature at 220°C, and carry out hydrothermal carbonization with a reaction time of 8 hours.

[0043]4. After the reaction is over, let the reaction kettle cool down to room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com