Preparation method of compact crystal form small-particle-size spherical cobalt carbonate

A cobalt carbonate, small particle size technology, applied in the direction of cobalt carbonate, positive electrode, active material electrode, etc., can solve the problems of unsatisfactory sphericity and tap density of cobalt trioxide, serious agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

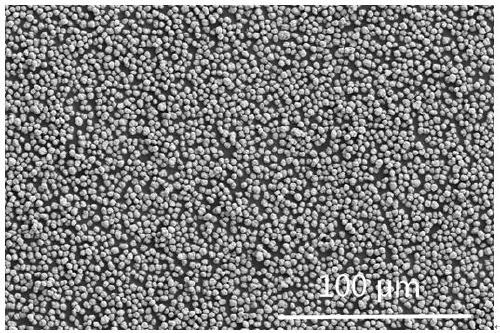

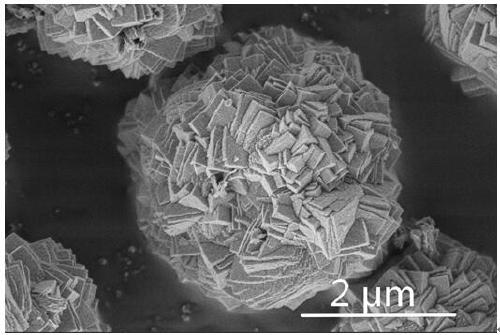

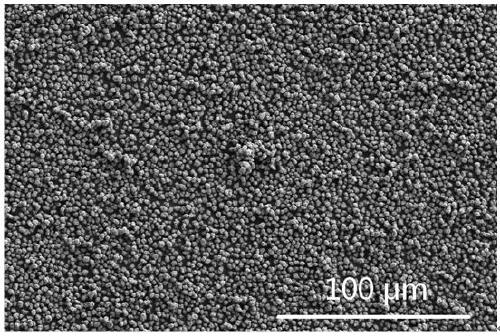

Image

Examples

Embodiment 1

[0029] Step 1. Preparation of solution: Weigh soluble aluminum salt and cobalt salt and add them into pure water to prepare a mixed salt solution containing aluminum as a raw material. The concentration of cobalt salt is 2 mol / L, and the mass ratio of aluminum to cobalt is 0.0063; The concentration is 2.9 mol / L ammonium bicarbonate solution;

[0030] Step 2, cobalt carbonate synthesis:

[0031] (1) Inject pure water and ammonium bicarbonate solution into the reactor as the bottom liquid, the ammonium bicarbonate concentration of the bottom liquid is 1.5 mol / L, the total bottom liquid volume accounts for 30% of the reactor volume, and sodium hexametaphosphate is added as a dispersant , the concentration is 3 g / L, and the pH value of the bottom solution is controlled at 8.5;

[0032] (2) In the first stage of liquid phase precipitation, firstly pump the mixed salt solution configured in step 1 into the second stage of liquid phase precipitation at a stirring speed of 280rpm for...

Embodiment 2

[0037] Step 1. Preparation of solution: Weigh soluble aluminum salt and cobalt salt and add them into pure water to prepare a mixed salt solution containing aluminum as a raw material. The concentration of cobalt salt is 1.7 mol / L, and the mass ratio of aluminum to cobalt is 0.013; The concentration is 2.2 mol / L ammonium bicarbonate solution;

[0038] Step 2, cobalt carbonate synthesis:

[0039] (1) Inject pure water and ammonium bicarbonate solution into the reactor as the bottom liquid, the concentration of the bottom liquid ammonium bicarbonate is 0.5 mol / L, the total bottom liquid volume accounts for 40% of the reactor volume, and add sodium hexametaphosphate as a dispersant , the concentration is 7 g / L, and the pH value of the bottom solution is controlled at 8.2;

[0040](2) In the first stage of liquid phase precipitation, firstly pump the mixed salt solution configured in step 1 separately for 2 hours at a stirring speed of 300 rpm, the reaction temperature is 45°C, a...

Embodiment 3

[0045] Step 1. Preparation of solution: Weigh soluble aluminum salt and cobalt salt and add them into pure water to prepare a mixed salt solution containing aluminum as a raw material. The concentration of cobalt salt is 2mol / L, and the mass ratio of aluminum to cobalt is 0.0067; 2.5mol / L ammonium bicarbonate solution;

[0046] Step 2, cobalt carbonate synthesis:

[0047] (1) Inject pure water and ammonium bicarbonate solution into the reactor as the bottom liquid, the concentration of the bottom liquid ammonium bicarbonate is 1.0 mol / L, the total bottom liquid volume accounts for 50% of the reactor volume, and add sodium hexametaphosphate as a dispersant , the concentration is 10 g / L, and the pH value of the bottom solution is controlled at 8.2;

[0048] (2) In the first stage of liquid phase precipitation, first pump the mixed salt solution prepared in step 1 separately for 1.5 hours at a stirring speed of 320rpm, and the reaction temperature is 30°C. After feeding until th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com