Electrochromic device with asymmetric electrode structure, preparation method thereof and application thereof

An electrochromic device and electrode structure technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve complex structure and packaging problems, affect the industrialization process, and slow device response speed, etc., to reduce the environment and human body damage, excellent electrochromic properties, the effect of good electrochromic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

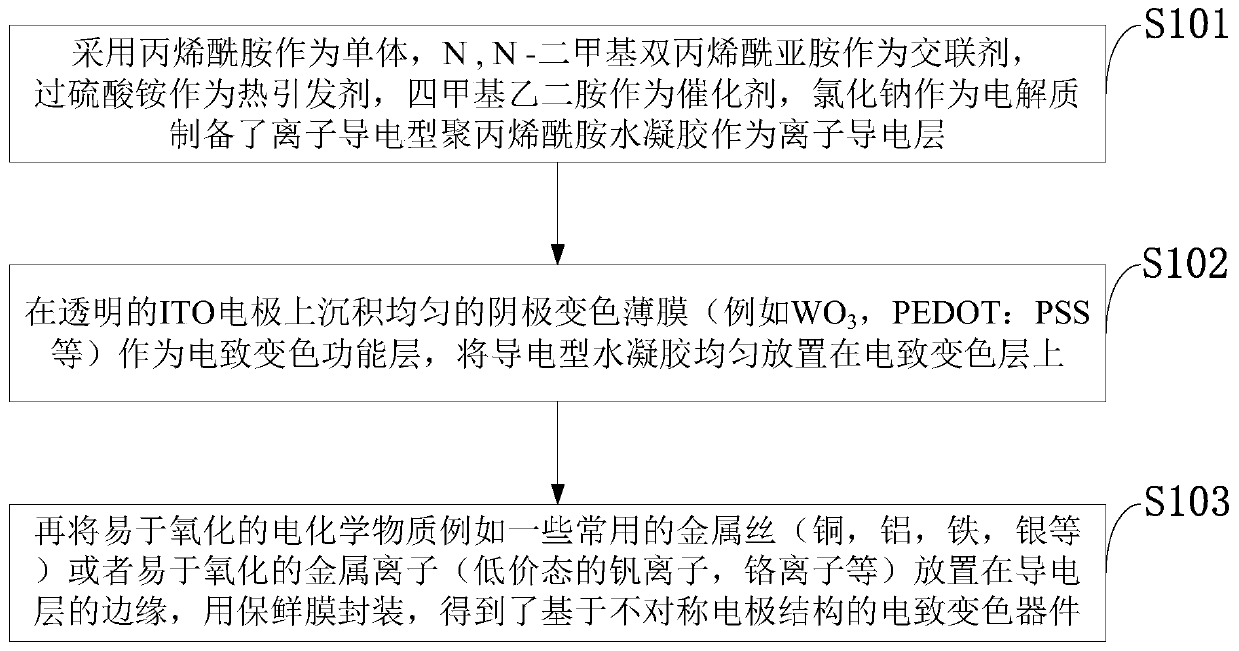

[0031] Such as figure 1 As shown, the preparation method of the electrochromic device with an asymmetric electrode structure provided by the embodiment of the present invention includes the following steps:

[0032] S101: Using acrylamide as a monomer, N,N-dimethylbisacrylimide as a crosslinking agent, ammonium persulfate as a thermal initiator, tetramethylethylenediamine as a catalyst, and sodium chloride as an electrolyte Ion-conducting polyacrylamide hydrogel as ion-conducting layer;

[0033] S102: Deposit a uniform cathodic color film (such as WO 3 , PEDOT: PSS, etc.) as the electrochromic functional layer, the conductive hydrogel is evenly placed on the electrochromic layer;

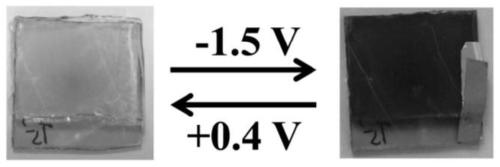

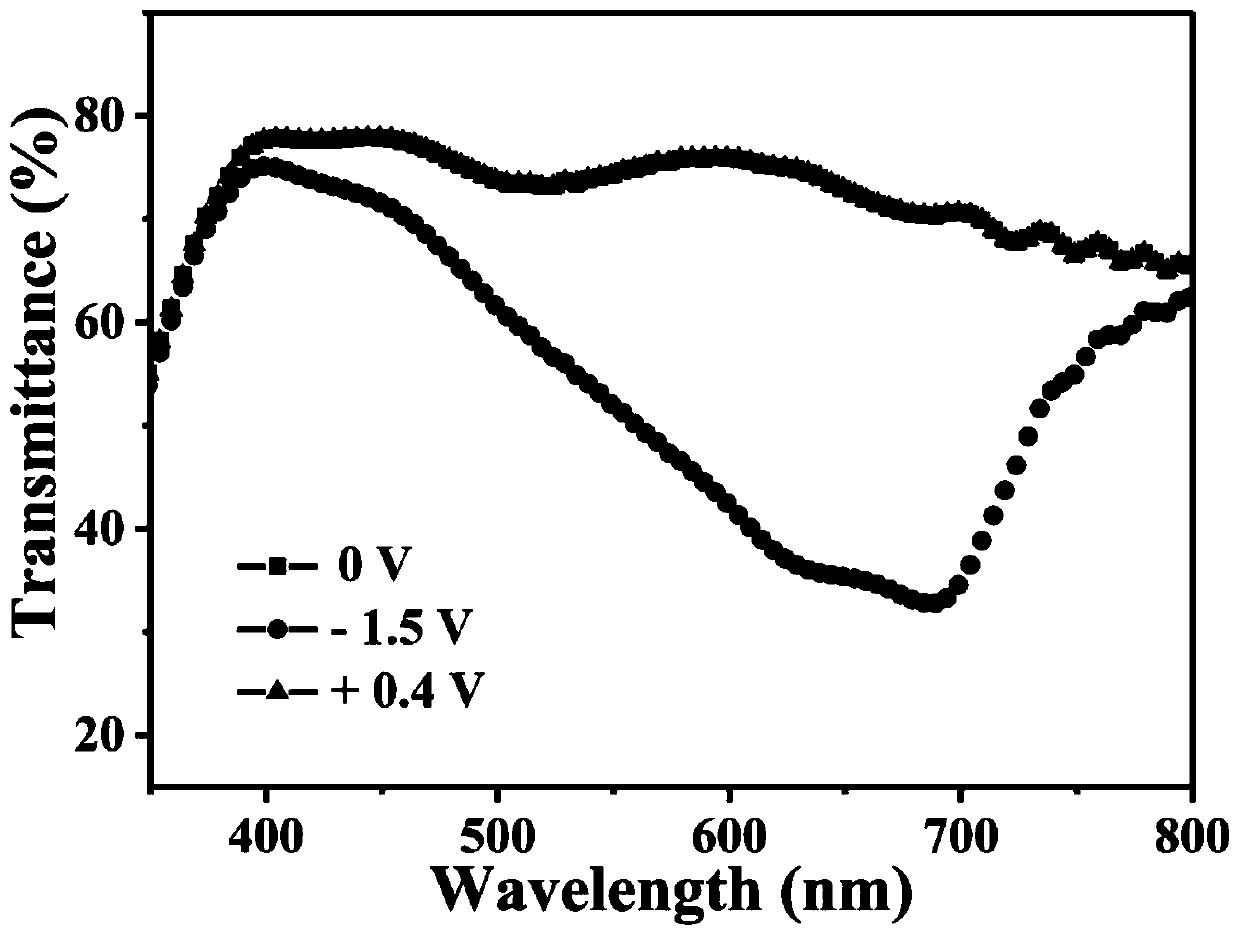

[0034] S103: Place easily oxidizable electrochemical substances such as some commonly used metal wires (copper, aluminum, iron, silver, etc.) or easily oxidizable metal ions (low-valence vanadium ions, chromium ions, etc.) on the edge of the conductive layer , and packaged with plastic wrap, an ...

Embodiment 1

[0041] The preparation method of the electrochromic device with an asymmetric electrode structure provided by the embodiment of the present invention specifically includes the following steps:

[0042] (1) Synthesis of ion-conducting layer material: The ion-conducting layer material here is a hydrogel doped with an electrolyte. Dissolve 4.773g of acrylamide monomer in 30mL of deionized water, add 5mg of N,N-dimethylbis Acrylimide, 10mg ammonium persulfate, 2g sodium chloride and 20mg tetramethylethylenediamine. The obtained solution was sealed and placed in a blast oven, and placed at 60° C. for 12 hours to obtain a colorless and transparent polyacrylamide hydrogel, which was washed with deionized water several times to remove residual monomers.

[0043] (2) Preparation of an electrode with an electrochromic functional layer: An electrochromic material (commercialized PEDOT:PSS dispersion) with cathodic coloring capability was deposited on an ITO electrode by spin coating to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com