Cyclohexene-based hexamethylenediamine preparation process

A preparation process and technology of cyclohexene, which are applied in the direction of reductive alkylation preparation, ozone oxidation preparation of carboxylic acid, catalyst activation/preparation, etc., can solve the problems of dependence on imports, high toxicity of adiponitrile, high price, etc. Effects of cleaning, improved selectivity and catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Cyclohexene oxidation is adipaldehyde in embodiment 1' microchannel reactor

[0061] 50 g of cyclohexene and 116 g of acetone were mixed to prepare a cyclohexene solution with a mass concentration of 30%, and 7.89 g of vanadyl acetylacetonate was added to the cyclohexene solution, and the mixed solution was obtained after ultrasonic vibration and uniform mixing;

[0062] A pump is used to inject the mixed solution into the microchannel reactor, and the flow rate of the mixed solution is 10g / min. At the same time, the mixed gas is injected into the microchannel reactor through a mass flow meter, and the flow rate of the mixed gas is controlled to be 15.1L / min. Composed of ozone, the ozone concentration is 100mg / L;

[0063] The reaction temperature in the microchannel reactor was 10° C., the reaction pressure was 0.10 MPa, and the materials were collected after 10 minutes of reaction, and analyzed by gas chromatography.

Embodiment 2

[0064] Cyclohexene is oxidized to adipaldehyde in embodiment 2'-11' microchannel reactor

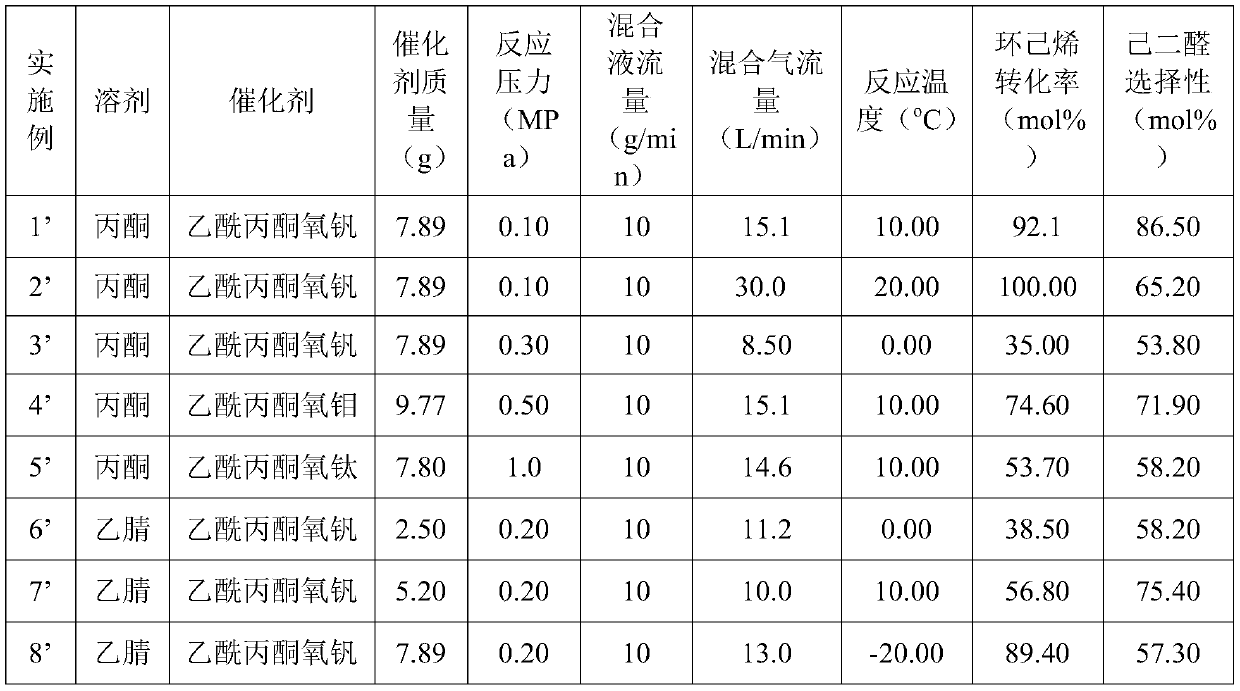

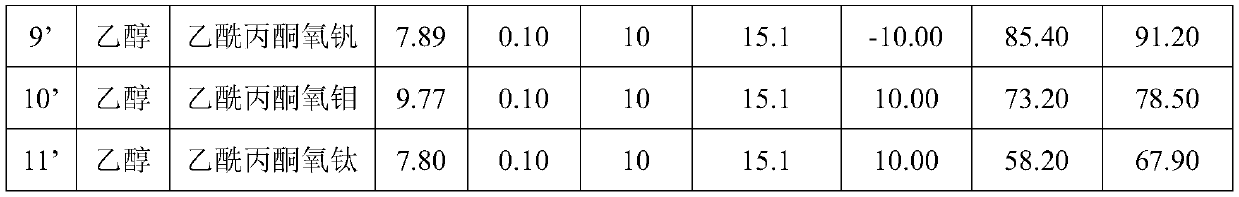

[0065] Adopt the described operation of embodiment 1 ', change the pressure of reaction, solvent, catalyzer and temperature of reaction to react, concrete reaction condition and result are shown in Table 1.

[0066] Table 1 Reaction conditions and result list of cyclohexene oxidation to adipaldehyde in microchannel reactor

[0067]

[0068]

[0069] As can be seen from Table 1, in the preparation process provided by the application, adipaldehyde generally has higher selectivity, and the selectivity of adipaldehyde can reach more than 53.8%, the highest can reach 91.2%, and the conversion rate of cyclohexene can reach 35.2% above, up to 100%.

Embodiment 1-10

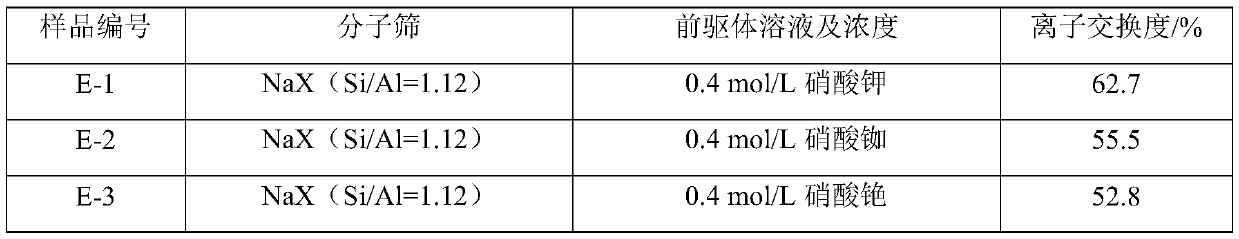

[0070] The preparation of embodiment 1-10 basic molecular sieve

[0071] Step 1): dissolving an alkali metal salt in water to obtain a precursor solution with a concentration of 0.2-0.6 mol / L, the alkali metal salt being selected from one of potassium nitrate, rubidium nitrate, and cesium nitrate;

[0072] Step 2): Weighing 30g molecular sieves, the molecular sieves are selected from one of NaX, NaY, KL, and NaBeta molecular sieves;

[0073] Step 3) According to the solid-to-liquid ratio of 10:1, use the alkali metal ion precursor solution in step 1) to carry out ion exchange on the molecular sieve weighed in step 2), exchange at 80°C for 4 hours, suction filter and wash 1. After drying, the obtained solid is roasted at 550° C. in a muffle furnace for 6 hours;

[0074] Step 4) Change the object of ion exchange in step 3) from the molecular sieve weighed in step 2) to the molecular sieve obtained after roasting, repeat step 3) twice to obtain a basic molecular sieve sample, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com