Preparation method of super-dispersed nano white carbon black

A nano-silica, ultra-dispersion technology, applied in chemical instruments and methods, dyeing polymer organic compound treatment, fibrous fillers, etc., can solve problems such as easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

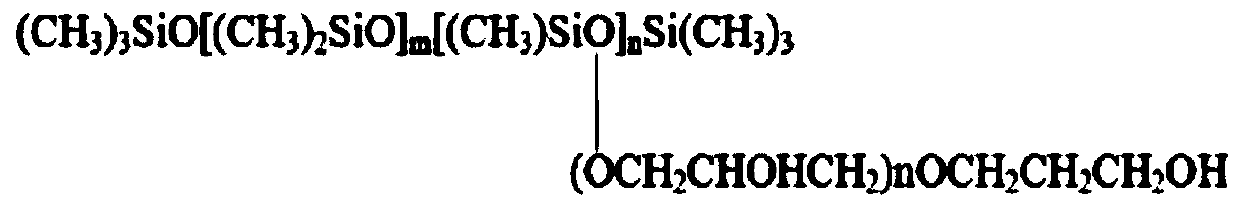

[0043] (1) Preparation of silicone / polyether polyol copolymer: first add 100 parts of KH-550 and 100 parts of cyclohexane into the reactor, stir for 1.0 hr, then add 10 parts of PPG, continue stirring and heating the reactor When the temperature reaches 95°C, 1.0 parts of potassium hydroxide is quickly added under stirring condition, and after reacting for 11 hours, it is depressurized and distilled to obtain KH-550 / PPG copolymer a.

[0044] (2) Preparation of haloacylated solution-polymerized styrene-butadiene mortar: first add 100 parts of solution-polymerized styrene-butadiene glue SSBR2564s and 100 parts of cyclohexane into the polymerization kettle, stir and heat, and when the temperature of the polymerization kettle reaches 40°C, Quickly add 0.08 part of AlCl under stirring condition 3 , until the system turns orange red, add 5 parts of phthalic anhydride, stir for 1 hr, then add 4 parts of liquid bromine, and drop 0.1 parts of HCl-CH 3 OH solution (the molar concentrat...

Embodiment 2

[0047] (1) Preparation of organosilicon / polyether polyol copolymer: same as Example 1.

[0048] (2) Preparation of haloacylated solution-polymerized styrene-butadiene mortar: same as in Example 1.

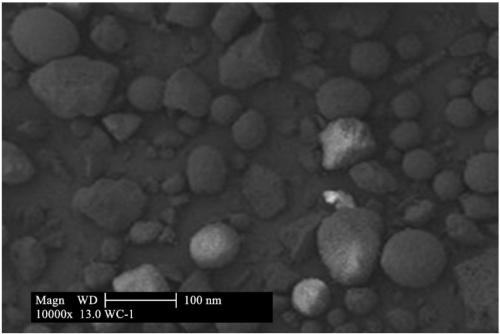

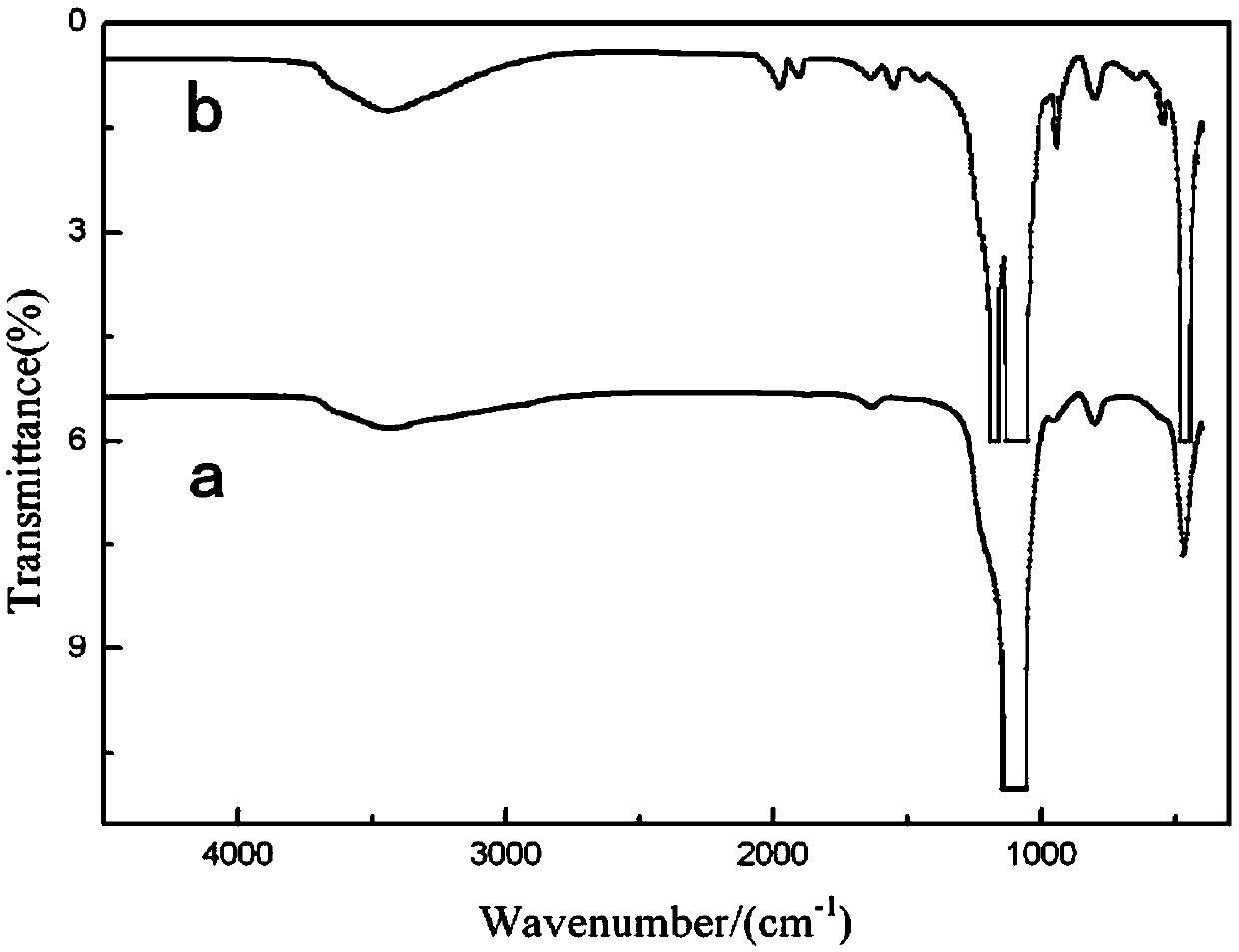

[0049] (3) Preparation of ultra-dispersed nano-silica: Take 100 parts of nano-silica (40nm), 6 parts of KH-550 / PPG copolymer a, and 230 parts of cyclohexane into the polymerization kettle, and heat up to 45°C , stirring and reacting for 1.5hr; then adding 7 parts of haloacylated solution polystyrene-butadiene mortar a, stirring and reacting for 2.6hr, and then flashing, drying and grinding to obtain ultra-dispersed nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0051] (1) Preparation of organosilicon / polyether polyol copolymer: same as Example 1.

[0052] (2) Preparation of haloacylated solution-polymerized styrene-butadiene mortar: same as in Example 1.

[0053] (3) Preparation of ultra-dispersed nano-silica: Take 100 parts of nano-silica (40nm), 7 parts of KH-550 / PPG copolymer a, and 270 parts of cyclohexane into the polymerization kettle, and heat up to 48°C , stirring and reacting for 1.8hr; then adding 9 parts of haloacylated solution polystyrene-butadiene mortar a, stirring and reacting for 2.9hr, and then flashing, drying and grinding to obtain ultra-dispersed nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com