Titanium dioxide/polyhexaaza-naphthalene triphenylamine core-shell structure composite film as well as preparation method and application of titanium dioxide/polyhexaaza-naphthalene triphenylamine core-shell structure composite film

A technology of naphthalene triphenylamine and titanium dioxide, which is applied in the field of titanium dioxide/polyhexaazanaphthalene triphenylamine core-shell structure composite film and its preparation field, can solve the problem that the performance of single-layer electrochromic film can not meet the requirements, polyhexaazapine Naphthalene triphenylamine has problems such as poor stability and limited application of electrochromic materials to achieve excellent electrochromic performance, low cost and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

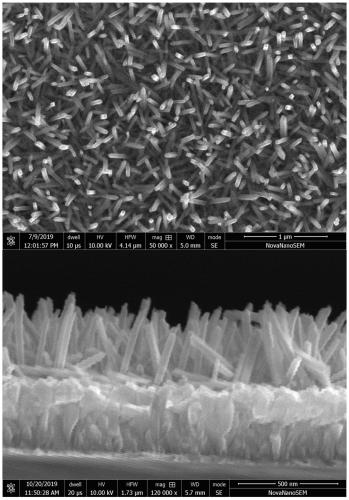

[0045] (1) Clean the FTO conductive glass substrate in an ultrasonic instrument, and dry it with nitrogen gas for later use. Measure 100ml of deionized water and 100ml of concentrated hydrochloric acid into a 250ml clean Erlenmeyer flask and stir for 10 minutes, then add 2.5ml of tetrabutyl titanate and stir for 15 minutes. After the solution is clear, transfer it to the lining of a polytetrafluoroethylene reactor , and then put the FTO conductive glass into the lining. Finally, put the lining in a stainless steel reaction kettle, put it in an oven at 150°C, and heat it for 3 hours. After the reaction, cool down to room temperature naturally, transfer the FTO, rinse the surface with deionized water and absolute ethanol, and dry it in an oven at 60°C for 2 hours to obtain FTO / TiO 2 electrode. The microscopic morphology of the surface was examined by scanning electron microscopy, such as figure 1 shown.

Embodiment 2

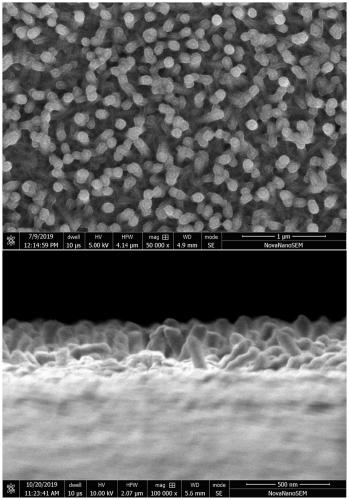

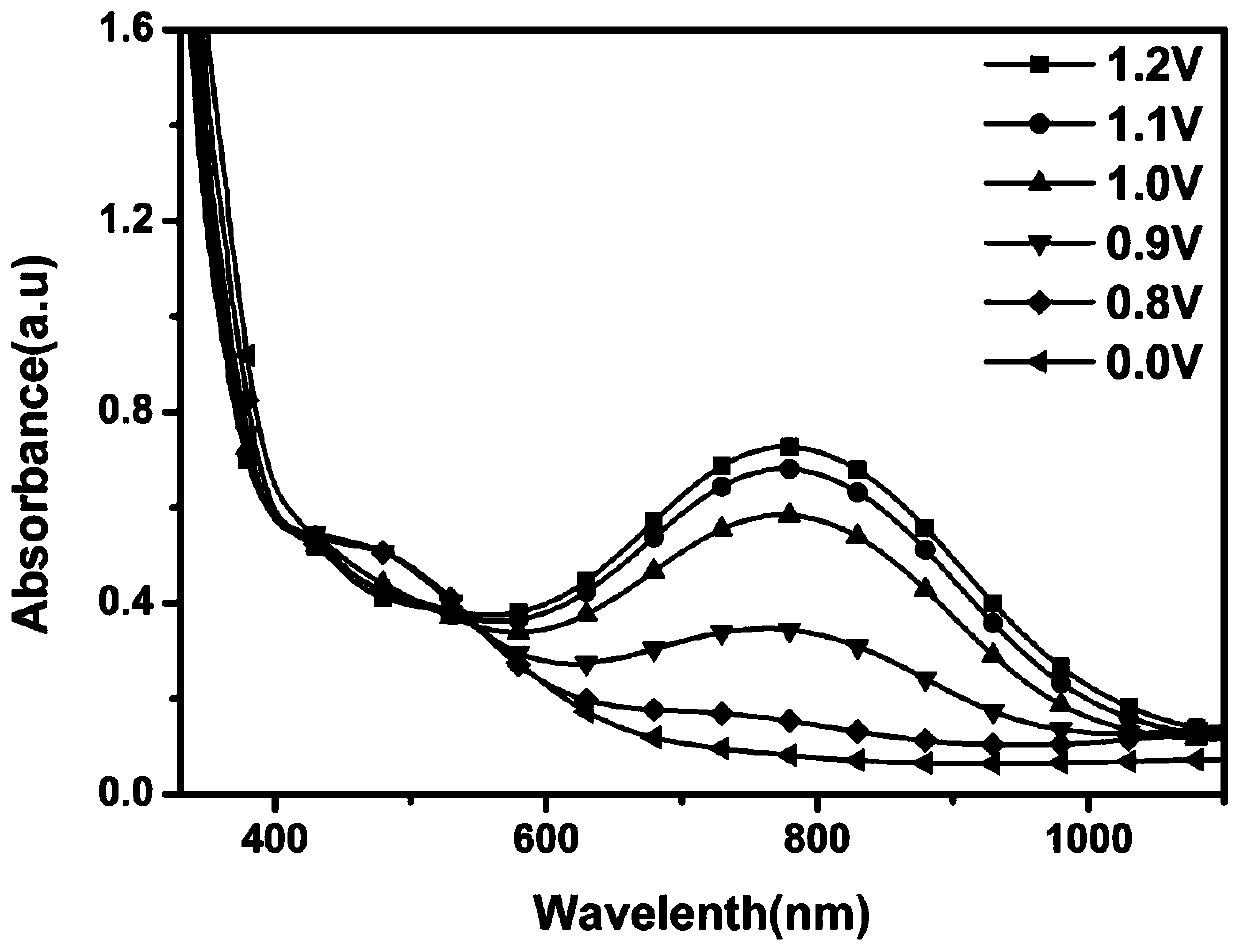

[0047] (1) In the three-electrode system electrolytic cell system, TPA-HATN (10.24mg, 0.0006mmol) was used as the monomer, tetra-n-butylammonium perchlorate (0.8548g, 0.0025mol) was used as the supporting electrolyte, and dichloro Methane (25mL) is electrolytic solvent, is mixed with monomer concentration 40mmol / L, the mixed solution 25mL of supporting electrolyte concentration 0.1mol / L, with the FTO / TiO in embodiment 1 2 The electrode is the working electrode, the platinum electrode is the auxiliary electrode, the silver / silver chloride electrode is the reference electrode, the saturated potassium chloride aqueous solution is the first liquid junction, and the electrolytic solution of the present invention is the second liquid junction. . At room temperature, use cyclic voltammetry -1.1 ~ 1.4V to carry out electrochemical polymerization reaction, the number of polymerization circles is 4 circles, and FTO / TiO 2 The orange-red polymer film on the working electrode was rinsed w...

Embodiment 3

[0050] (1) In the three-electrode system electrolytic cell system, TPA-HATN (10.24mg, 0.0006mmol) was used as the monomer, tetra-n-butylammonium perchlorate (0.8548g, 0.0025mol) was used as the supporting electrolyte, and dichloro Methane (25mL) is electrolytic solvent, is mixed with monomer concentration 40mmol / L, the mixed solution 25mL of supporting electrolyte concentration 0.1mol / L, with the FTO / TiO in embodiment 1 2 The electrode is the working electrode, the platinum electrode is the auxiliary electrode, the silver / silver chloride electrode is the reference electrode, the saturated potassium chloride aqueous solution is the first liquid junction, and the electrolytic solution of the present invention is the second liquid junction. . At room temperature, use cyclic voltammetry -1.1 ~ 1.4V to carry out electrochemical polymerization reaction, the number of polymerization circles is 4 circles, and FTO / TiO 2 The orange-red polymer film on the working electrode was rinsed w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coloring time | aaaaa | aaaaa |

| Coloring time | aaaaa | aaaaa |

| Coloring time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com