High-power and high-voltage-resistant lithium ion battery electrolyte and preparation method thereof

A lithium-ion battery and electrolyte technology, which is used in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, electrolytes, etc. Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention discloses a method for preparing a high-voltage lithium-ion battery electrolyte, comprising the following steps:

[0028] In an inert environment full of argon, ethylene carbonate, ethyl methyl carbonate, and dimethyl carbonate were respectively added to a container to form a mixed non-aqueous organic solvent; then lithium hexafluorophosphate was dissolved in the mixed non-aqueous organic solvent, and then Add film-forming functional additives vinylene carbonate and difluoroethylene carbonate to prepare an electrolyte solution, and finally seal the prepared electrolyte solution and store it for 24 hours.

Embodiment 1

[0031] In an inert environment filled with argon, ethylene carbonate, ethyl methyl carbonate, and dimethyl carbonate were added to the container at a volume ratio of 4:2:1 to form a mixed non-aqueous organic solvent, and then lithium hexafluorophosphate was dissolved in In the mixed non-aqueous organic solvent, then add film-forming functional additives vinylene carbonate and difluoroethylene carbonate at a mass ratio of 1:10 to prepare an electrolyte solution containing 1.1M lithium hexafluorophosphate, wherein the mass percentage of each raw material is composed of : Non-aqueous organic solvent accounts for 84%, lithium salt accounts for 14%, and film-forming functional additive accounts for 2%. Finally, the prepared electrolyte is sealed and stored for 24 hours. The electrical conductivity of the obtained electrolytic solution was 9.5 mS / cm.

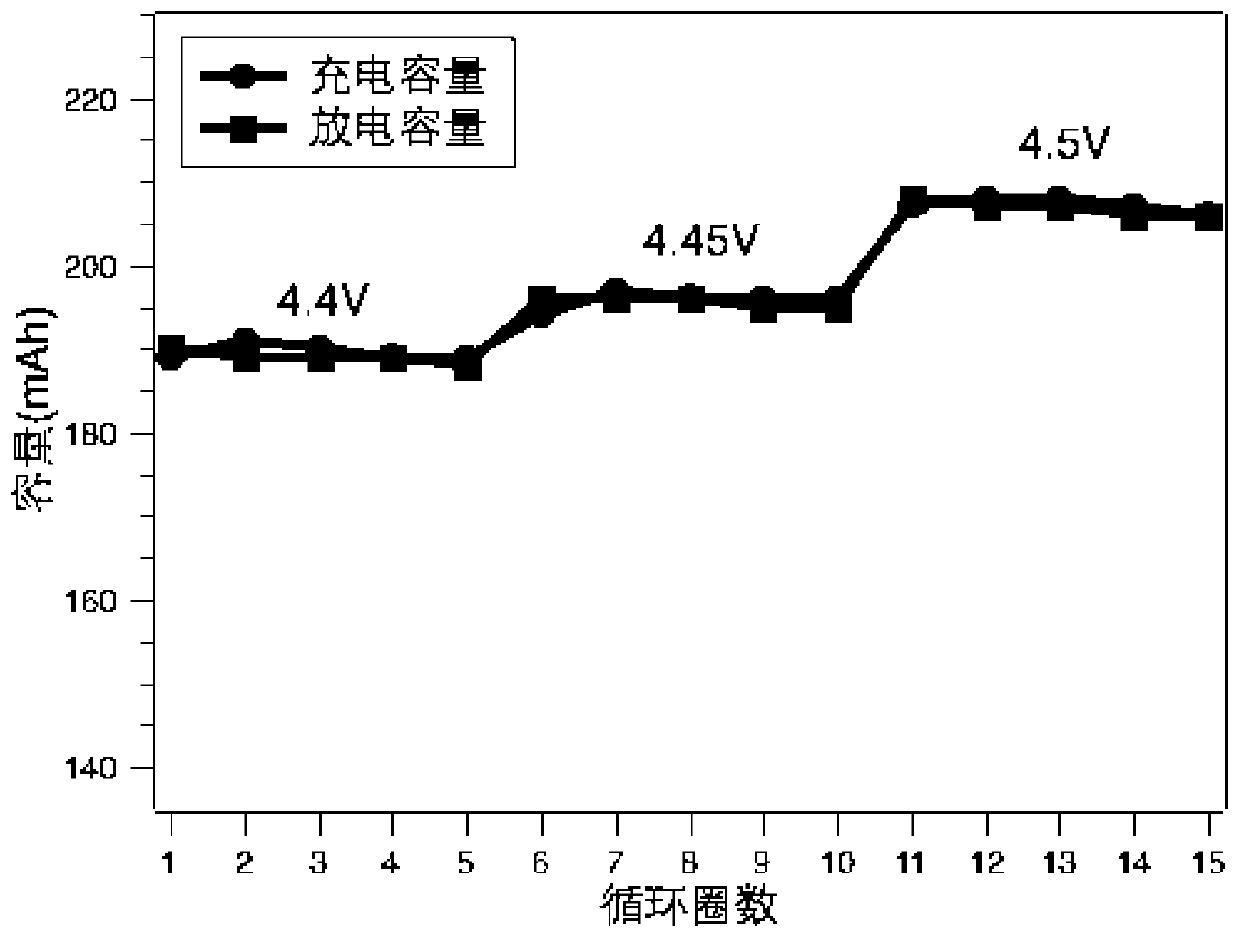

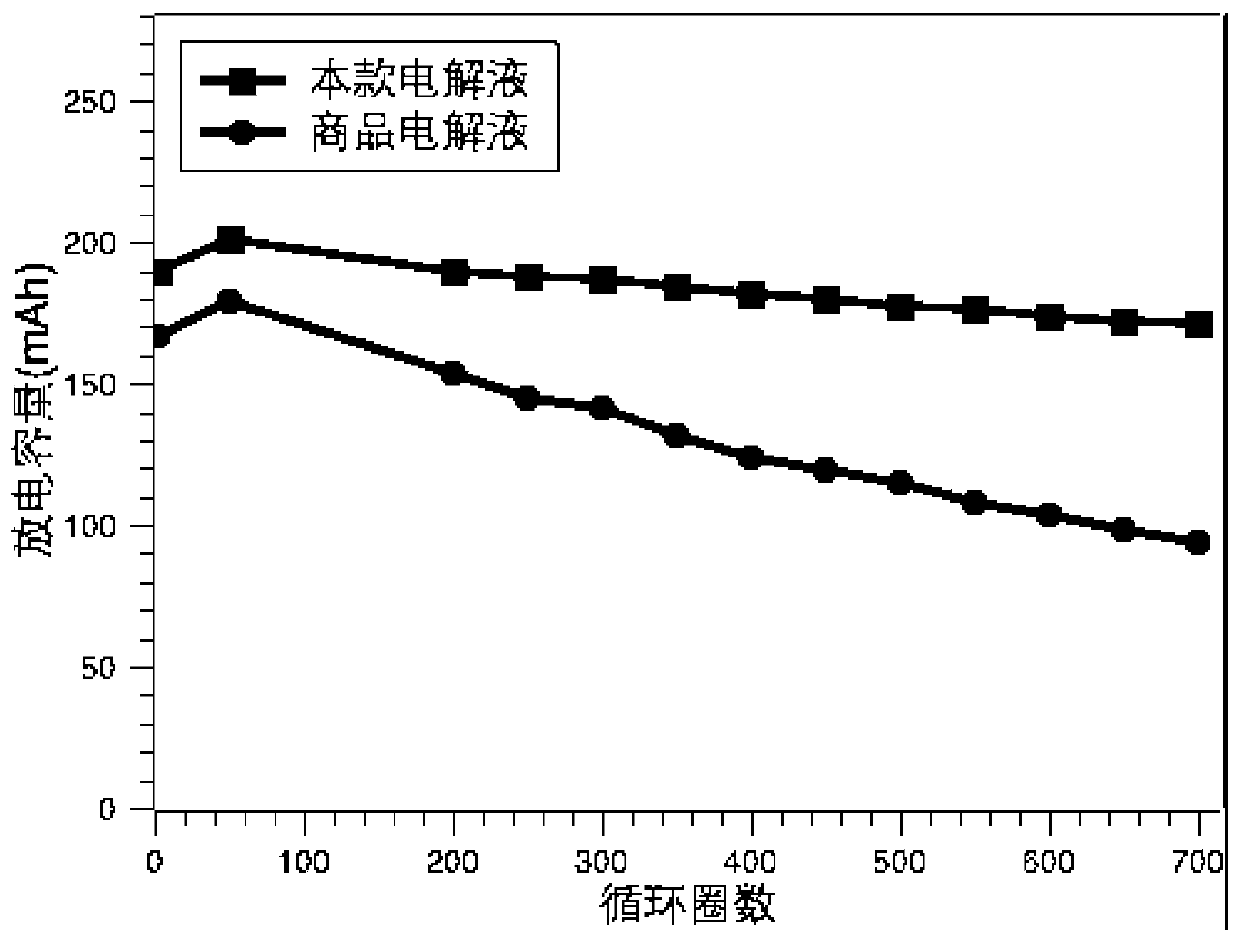

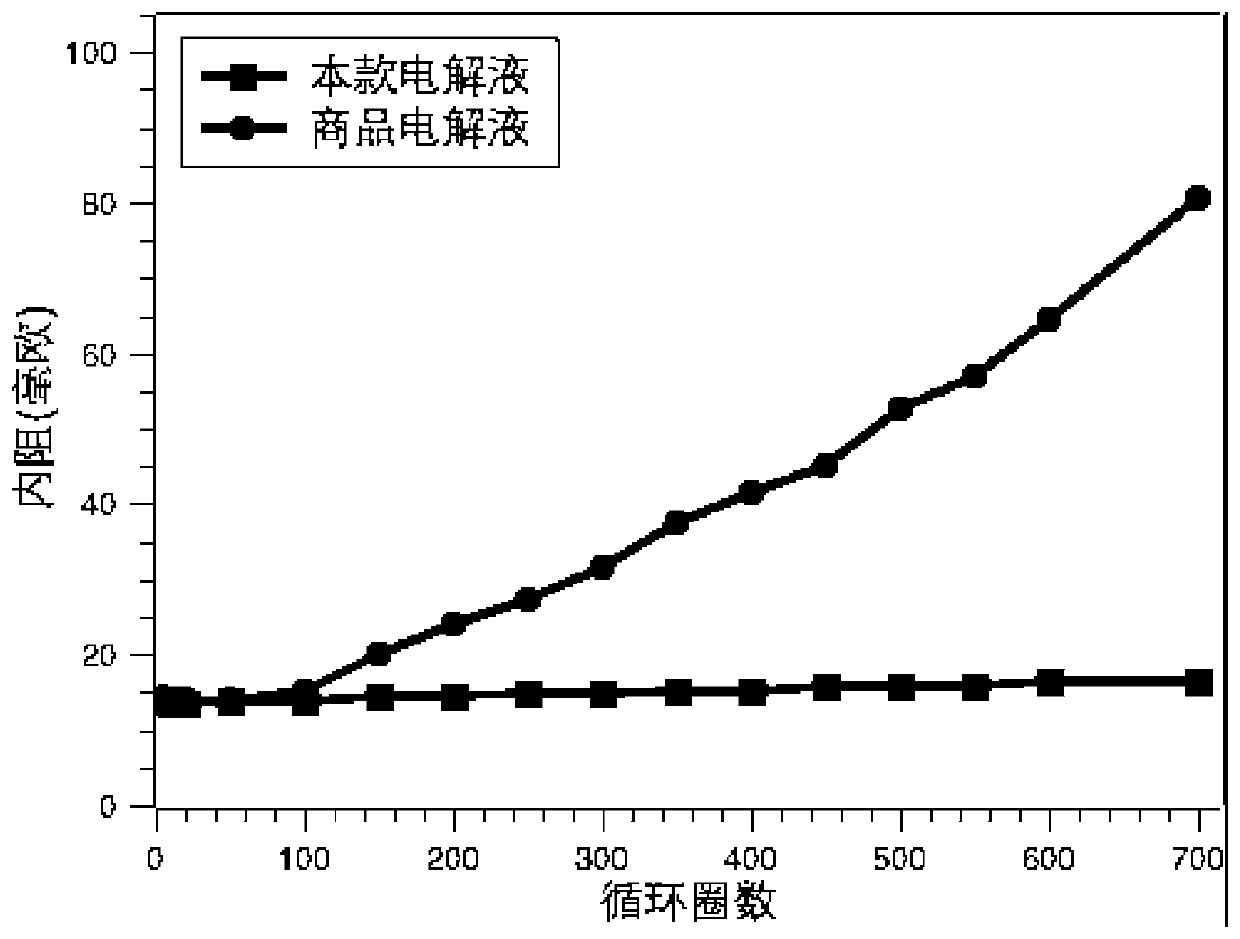

[0032] Prepare the positive pole of high-voltage lithium cobaltate, the negative pole of graphite + hard carbon, and a test soft-pac...

Embodiment 2

[0035] In an inert environment filled with argon, ethylene carbonate, ethyl methyl carbonate, and dimethyl carbonate were added to the container at a volume ratio of 6:3:2 to form a mixed non-aqueous organic solvent, and then lithium hexafluorophosphate was dissolved in In the mixed non-aqueous organic solvent, then add film-forming functional additives vinylene carbonate and difluoroethylene carbonate in a mass ratio of 3:20 to prepare an electrolyte containing 1.2M lithium hexafluorophosphate, wherein the mass percentage of each raw material is composed of : Non-aqueous organic solvent accounts for 80%, lithium salt accounts for 16%, and film-forming functional additive accounts for 4%. Finally, the prepared electrolyte solution is sealed and stored for 24 hours. The electrical conductivity of the obtained electrolytic solution was 10.1 mS / cm.

[0036] Prepare the positive pole of high-voltage lithium cobalt oxide, the negative pole of graphite + hard carbon, and a test soft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com