Process for removing vanadium from crude titanium tetrachloride

A crude titanium tetrachloride and process technology, applied in the direction of titanium tetrachloride, titanium halide, etc., can solve the problem of residues affecting heat transfer and the like, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

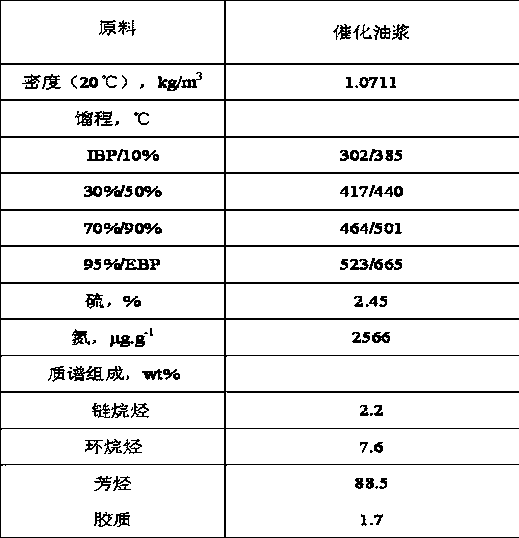

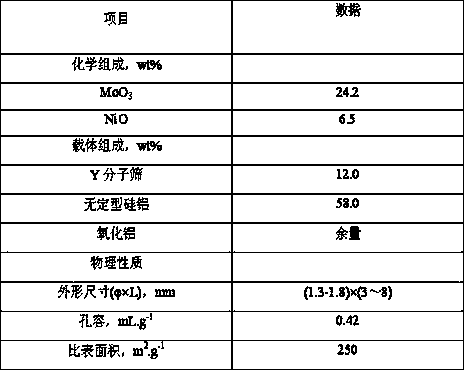

[0033]The catalytic cracking diesel in Table 1 is used as the raw material, the hydrogenation catalyst listed in Table 2 is used as the catalyst, and the catalyst is sulfided according to the conventional method before implementation. The raw material enters a hydrogenation reaction zone filled with a hydrogenation catalyst, and the hydrogenation reaction is carried out under the condition of hydrogen, and the liquid phase material obtained after fractional distillation of the reaction product is used as a vanadium removal reagent. The hydrogenation reaction process conditions are: reaction temperature 393°C, reaction pressure 10.0MPa, hydrogen to oil volume ratio 1100, volume space velocity 0.85h -1 . The properties of the obtained liquid phase material are specifically shown in Table 3.

Embodiment 2

[0035] The catalytic cracking diesel in Table 1 is used as the raw material, the hydrogenation catalyst listed in Table 2 is used as the catalyst, and the catalyst is sulfided according to the conventional method before implementation. The raw material enters a hydrogenation reaction zone filled with a hydrogenation catalyst, and the hydrogenation reaction is carried out under the condition of hydrogen, and the liquid phase material obtained after fractional distillation of the reaction product is used as a vanadium removal reagent. The hydrogenation reaction process conditions are: reaction temperature 400°C, reaction pressure 16.0MPa, hydrogen to oil volume ratio 1300, volume space velocity 1.0h -1 . The properties of the obtained liquid phase material are specifically shown in Table 3.

[0036] Table 3 Properties of liquid phase materials

[0037] Example 1 Example 2 Distillation range / ℃ >250 >250 Composition, wt% Paraffins 7.3 14.0 ...

Embodiment 3

[0039] The liquid phase material prepared in Example 1 is used as a vanadium removal reagent, and the vanadium removal of crude titanium tetrachloride is carried out in an evaporation tower. The evaporation tower has 15 trays, and the pressure at the top of the evaporation tower is 101KPa-110KPa. The crude titanium tetrachloride preheated to 135°C enters the 13th tray in the middle and lower part of the evaporation tower, and the vanadium removal composition heated to 362°C enters the third tray in the upper part of the evaporation tower. The mass ratio of vanadium removal reagent to crude titanium tetrachloride is 2.5:100. The two streams are countercurrently contacted in the evaporation tower to remove vanadium, and the steam at the top of the evaporation tower is condensed to be refined titanium tetrachloride, which is analyzed by ICP spectrometer, and the vanadium oxytrichloride content is less than 0.001wt%. The generated residue is discharged from the lower part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com